In today's competitive healthcare landscape, medical device manufacturers face mounting pressure to reduce production costs while maintaining the highest quality standards. Custom OEM molding services have emerged as a strategic solution for companie...

VIEW MORESelecting the appropriate medical-grade tubing and catheters for complex surgical procedures represents one of the most critical decisions healthcare professionals make in their practice. The complexity of modern surgical interventions demands materi...

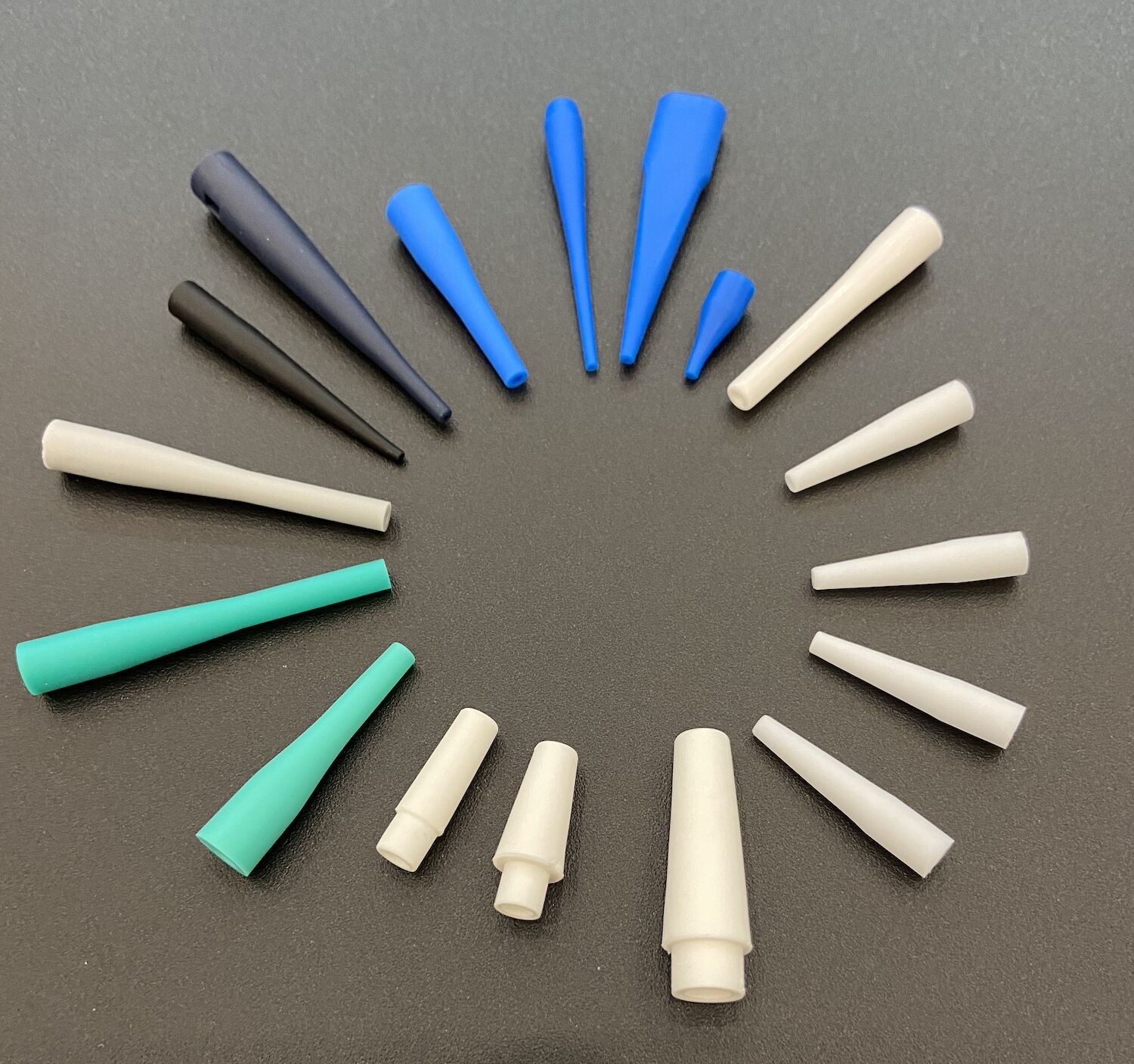

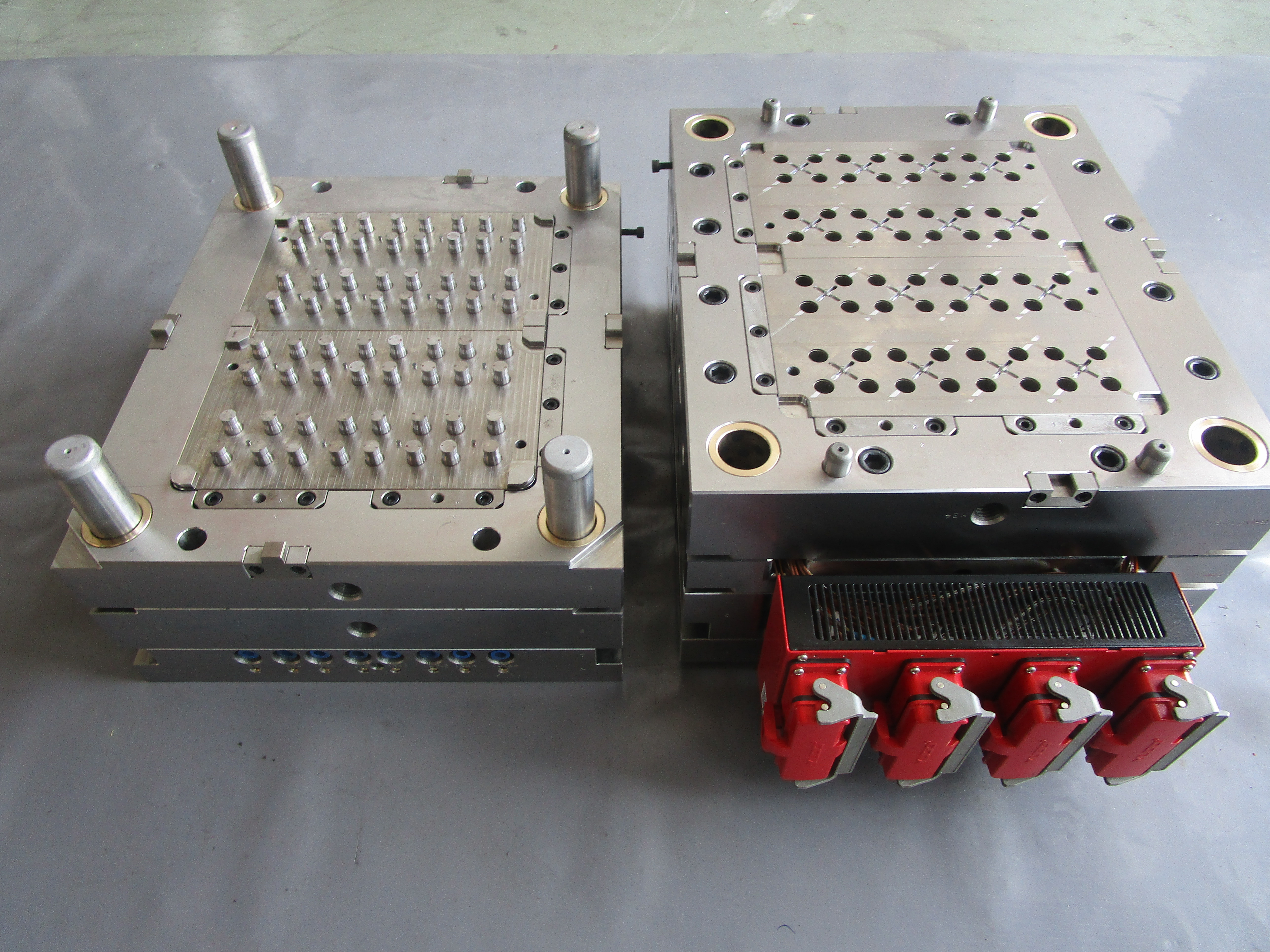

VIEW MOREThe manufacturing of life-saving medical devices demands unwavering precision, safety, and reliability at every stage of production. At the heart of this critical process lies the medical plastic injection mold, a sophisticated manufacturing tool tha...

VIEW MOREMedical device manufacturing demands precision, compliance, and reliability at every stage of production. When selecting a partner for custom mold development and OEM molding services, healthcare companies must evaluate multiple critical factors that...

VIEW MOREThe healthcare industry continues to evolve at an unprecedented pace, driven by technological advancements and increasing patient care demands. Modern healthcare facilities require sophisticated medical equipment that not only meets current clinical ...

VIEW MORE

Manufacturing efficiency has become the cornerstone of competitive advantage in today's industrial landscape. Companies across various sectors are discovering that traditional manufacturing approaches often fall short of meeting modern demands for pr...

VIEW MORE

Insert injection molding represents a revolutionary manufacturing process that seamlessly combines different materials, particularly metals and plastics, to create composite components with enhanced functionality and durability. This advanced techniq...

VIEW MORE

Manufacturing companies across industries increasingly rely on custom mold solutions to create precise, high-quality components that meet their specific requirements. The decision to invest in custom mold fabrication represents a significant strategi...

VIEW MORE

Manufacturing industries across the globe rely heavily on precision components that meet exact specifications and performance standards. When standard off-the-shelf products cannot deliver the required functionality, companies turn to specialized man...

VIEW MORE

Selecting the right supplier for your custom mold and OEM molding projects represents one of the most critical decisions in manufacturing. The success of your product development, production timelines, and overall profitability directly depends on pa...

VIEW MORE

The manufacturing landscape has witnessed remarkable transformations over the past decades, with injection moulding emerging as one of the most critical production processes across multiple industries. From automotive components to medical devices, c...

VIEW MORESelecting the right injection manufacturer is a critical decision that can significantly impact your product quality, production timelines, and overall business success. Whether you're developing medical devices, automotive components, or consumer pr...

VIEW MORE