The manufacturing landscape for injection molding has evolved dramatically over the past decade, with companies facing increasing demands for precision, efficiency, and cost-effectiveness. As industries ranging from automotive to medical devices requ...

VIEW MORE

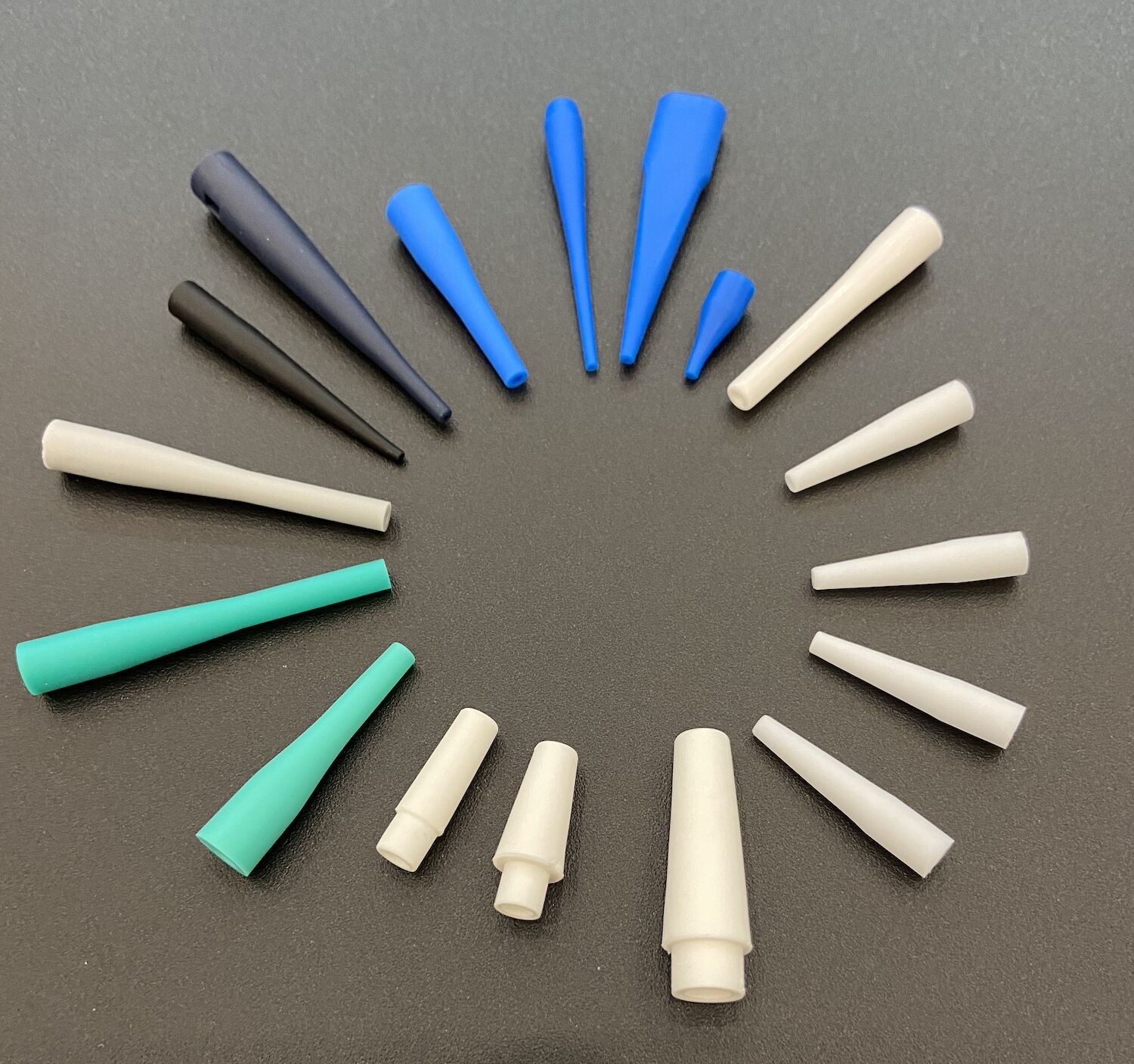

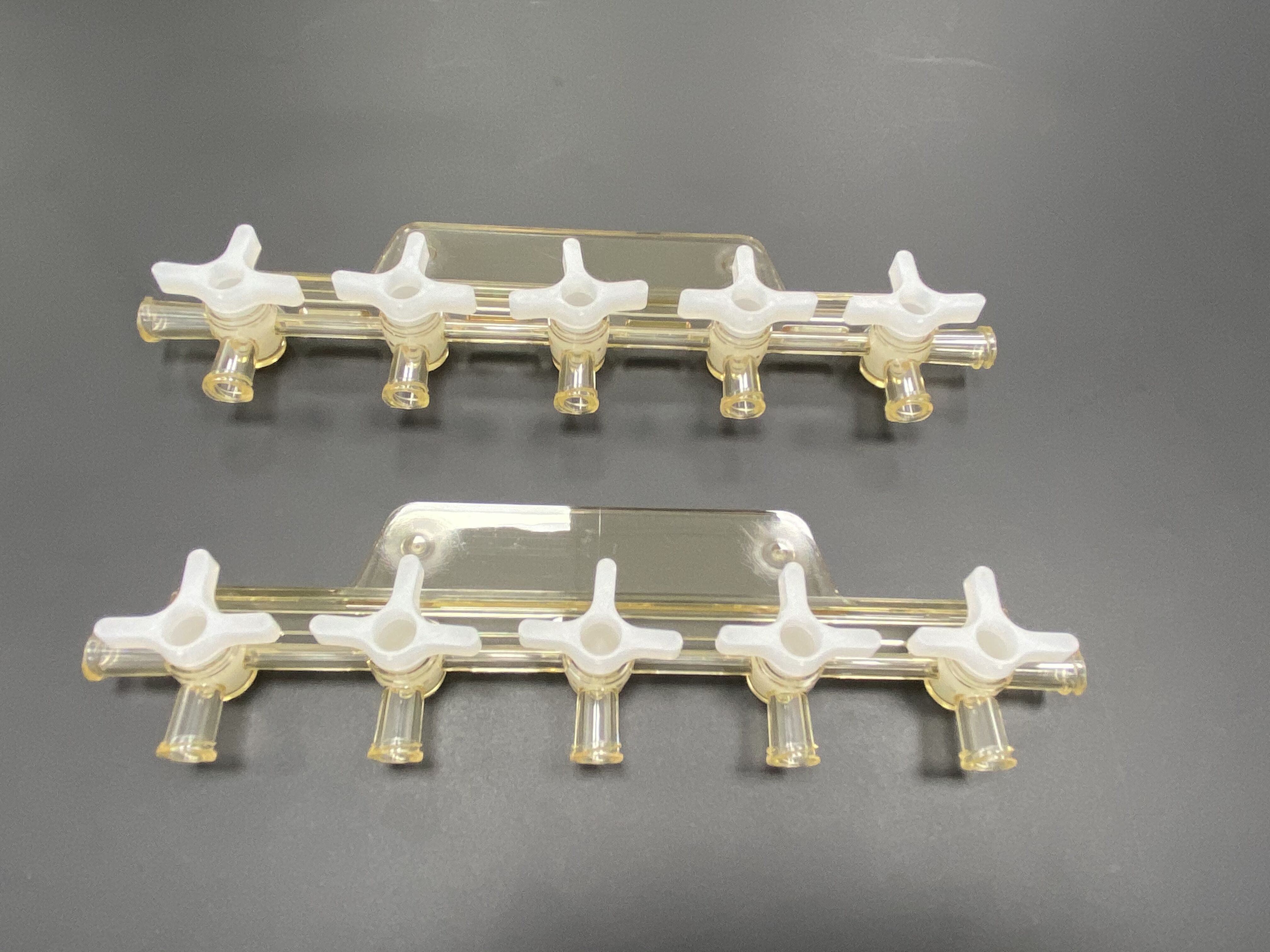

The medical device industry demands precision and reliability at every stage of production, making the selection of experienced injection manufacturers a critical decision for companies developing healthcare products. Quality standards in medical man...

VIEW MOREIn today's competitive manufacturing landscape, partnering with a reliable injection manufacturer has become crucial for businesses across various industries. From medical devices to automotive components, plastic injection molding remains one of the...

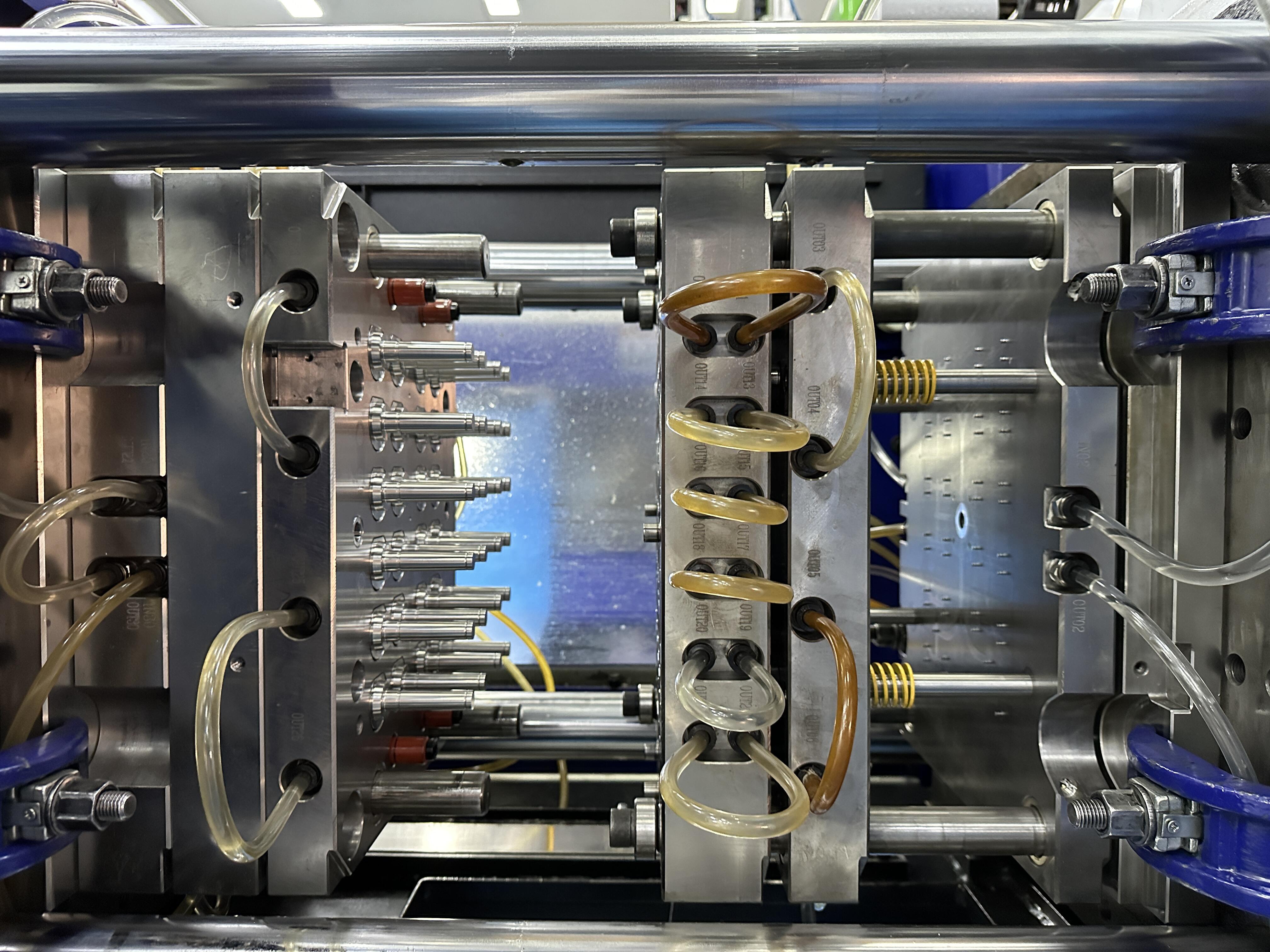

VIEW MOREMastering the Art of Precision Manufacturing Through Injection Molding The manufacturing landscape continues to evolve, and custom injection molding stands at the forefront of modern production techniques. This sophisticated process has revolutionize...

VIEW MORE

Revolutionizing Manufacturing Through Custom Injection Molding The manufacturing landscape has evolved dramatically in recent years, with custom injection molding services emerging as a cornerstone of modern production methods. This sophisticated man...

VIEW MORE

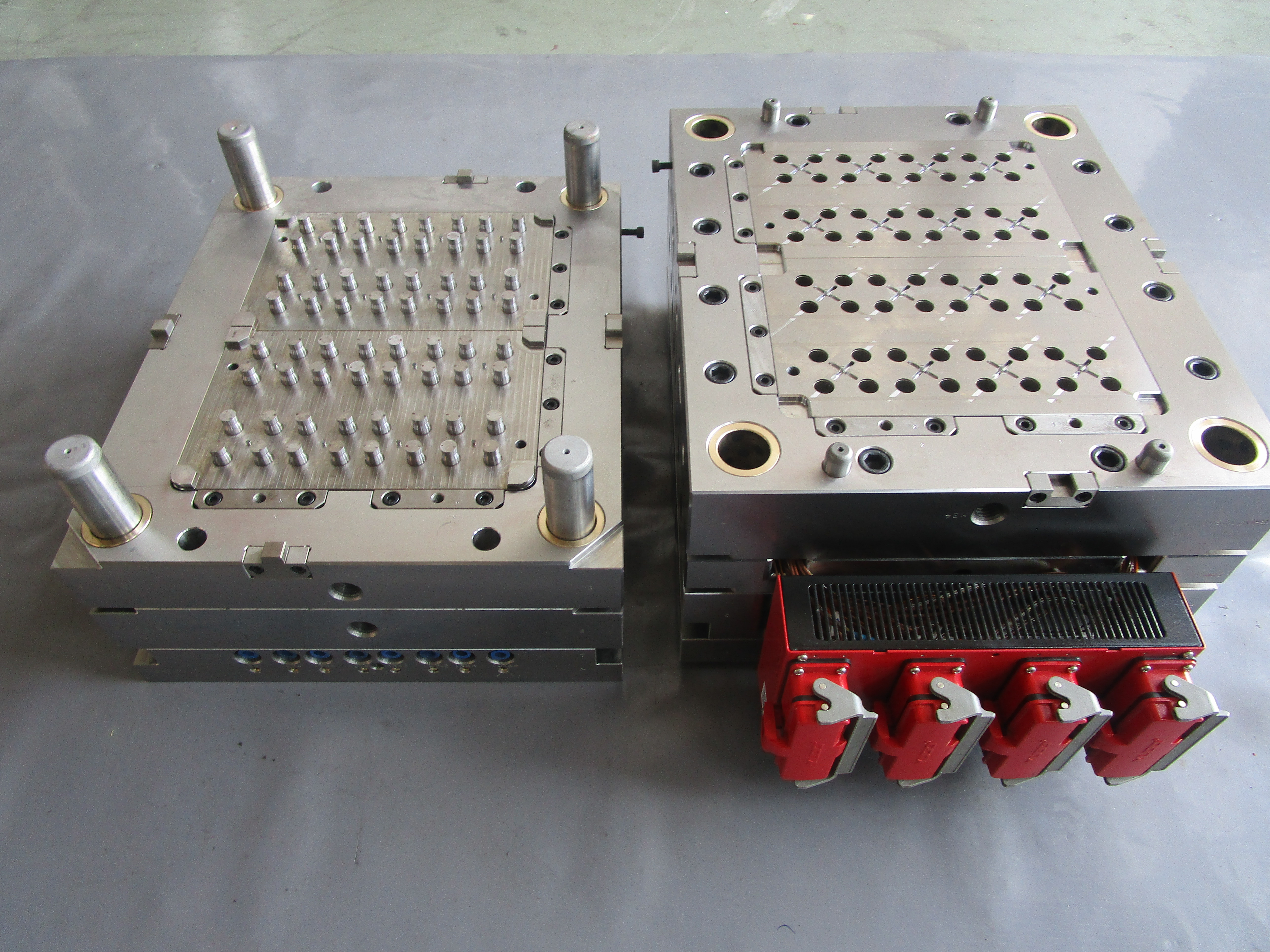

Understanding the Core Distinctions of Original Equipment Manufacturing Tools The manufacturing industry relies heavily on precision tools and equipment to create high-quality products. When it comes to tooling solutions, there's often confusion betw...

VIEW MORE

Understanding the Complex World of Advanced Manufacturing Technologies The realm of precision OEM tooling represents one of manufacturing's most demanding sectors, where tolerances are measured in microns and quality standards are uncompromising. As ...

VIEW MORE

The Evolution of Modern Manufacturing Through Custom Molding Solutions In today's advanced manufacturing landscape, precision and consistency are paramount. Custom injection molding has emerged as a cornerstone technology that enables manufacturers t...

VIEW MORE

Understanding the Strategic Value of Original Equipment Manufacturing Tools In today's competitive manufacturing landscape, OEM tooling represents a cornerstone of efficient and high-quality production processes. These specialized tools and equipment...

VIEW MORE

Essential Considerations for Selecting Manufacturing Partners The success of any manufacturing operation heavily depends on partnering with the right OEM tooling providers. These specialized manufacturers serve as the backbone of production processes...

VIEW MOREUnderstanding the Evolution of Medical Device Manufacturing The medical device industry has witnessed remarkable transformations in recent years, with OEM molding emerging as a cornerstone of modern healthcare equipment production. This sophisticated...

VIEW MORE

Maximizing Production Efficiency Through Strategic Equipment Care The manufacturing industry's backbone lies in its tooling systems, and proper OEM tooling maintenance stands as a critical factor in ensuring continuous, efficient operations. When pre...

VIEW MORE