The medical device industry demands precision and reliability at every stage of production, making the selection of experienced injection manufacturers a critical decision for companies developing healthcare products. Quality standards in medical manufacturing have evolved significantly, requiring specialized expertise that only seasoned injection molding professionals can provide. When healthcare organizations partner with established injection manufacturers, they gain access to decades of accumulated knowledge, refined processes, and proven quality control systems that directly impact patient safety and regulatory compliance.

Manufacturing excellence in the injection molding sector stems from understanding the intricate relationship between material properties, process parameters, and final product performance. Experienced professionals recognize that each medical device presents unique challenges requiring tailored solutions, advanced tooling strategies, and meticulous attention to detail throughout the production cycle.

Advanced Process Control and Quality Assurance Systems

Precision Temperature and Pressure Management

Seasoned injection manufacturers implement sophisticated temperature control systems that maintain consistent heat distribution throughout the molding process. These systems utilize advanced heating elements, precise thermocouples, and real-time monitoring software to ensure optimal material flow and proper curing. Temperature variations of even a few degrees can significantly impact the mechanical properties of medical-grade plastics, making this level of control essential for consistent product quality.

Pressure management represents another critical aspect where experience proves invaluable. Veteran manufacturers understand how injection pressure, holding pressure, and back pressure interact to influence part density, dimensional accuracy, and surface finish. They employ progressive pressure profiles that adapt to specific material characteristics, ensuring complete mold cavity filling while minimizing internal stresses that could compromise long-term durability.

Statistical Process Control Implementation

Experienced injection manufacturers utilize comprehensive statistical process control methodologies to monitor and optimize production parameters continuously. These systems collect real-time data from multiple sensors throughout the molding process, analyzing trends and identifying potential quality issues before they result in defective parts. Advanced SPC software enables predictive maintenance scheduling, reducing unexpected downtime and maintaining consistent production output.

Quality metrics tracking extends beyond basic dimensional measurements to include material flow analysis, cycle time optimization, and energy consumption monitoring. This holistic approach to process control enables manufacturers to identify subtle correlations between different variables, leading to continuous improvement opportunities that enhance overall product quality while reducing manufacturing costs.

Material Expertise and Selection Optimization

Medical-Grade Polymer Knowledge

Veteran injection manufacturers possess extensive knowledge of medical-grade polymers, including their processing requirements, biocompatibility characteristics, and performance limitations. This expertise enables them to recommend optimal material selections based on specific application requirements, regulatory constraints, and cost considerations. Understanding polymer behavior during processing helps prevent common issues such as degradation, contamination, and inconsistent mechanical properties.

Material handling and preparation protocols developed through years of experience ensure consistent feedstock quality and processing stability. Experienced manufacturers implement proper drying procedures, contamination prevention measures, and material storage systems that preserve polymer integrity throughout the production cycle. These practices are particularly crucial for hygroscopic materials that can absorb moisture and compromise final product quality.

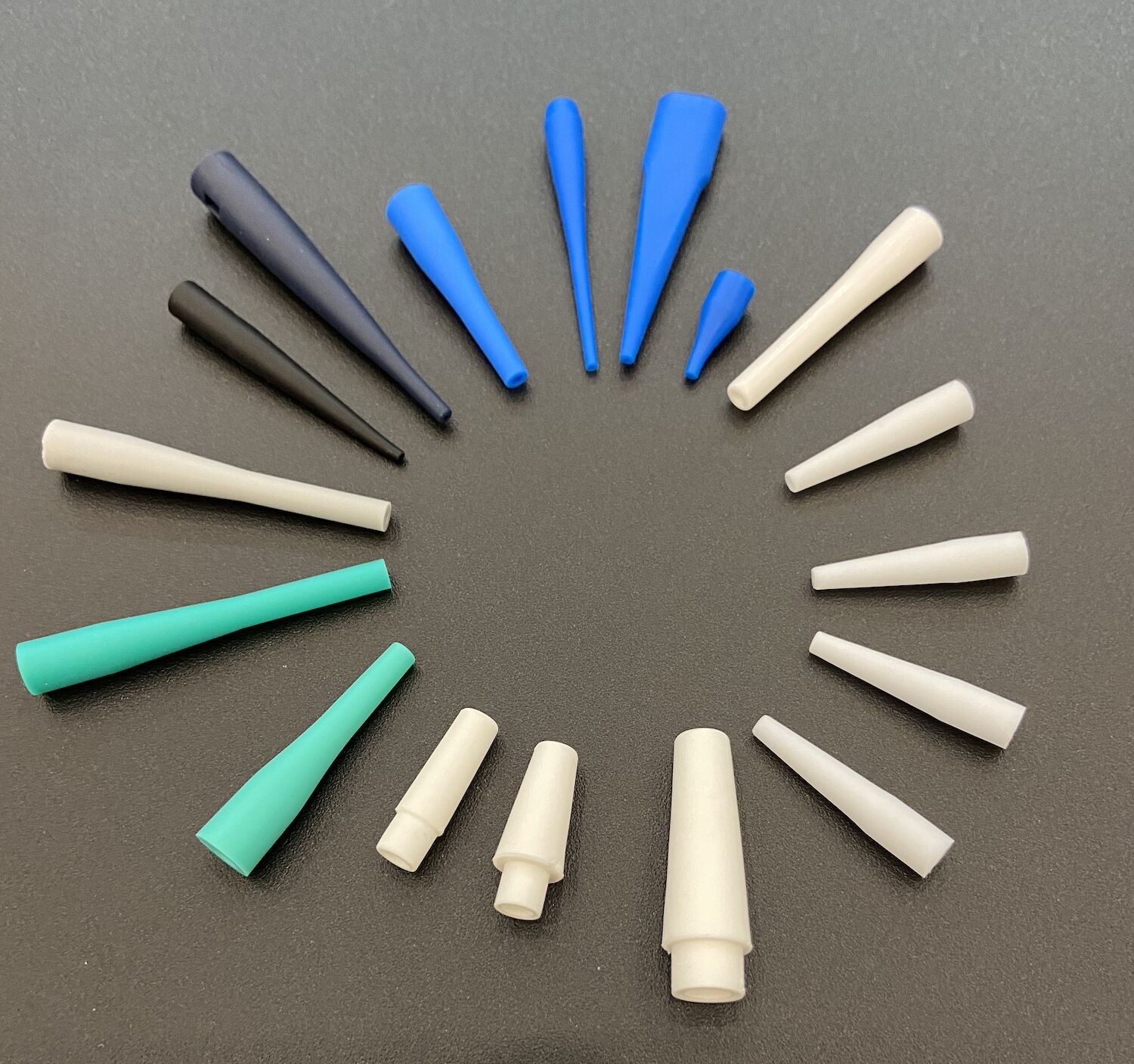

Additive Integration and Colorant Systems

Complex medical devices often require specialized additives such as antimicrobial agents, radiopaque fillers, or UV stabilizers. Experienced injection manufacturers understand how these additives interact with base polymers and processing conditions, ensuring uniform distribution and consistent performance characteristics. Proper additive incorporation requires precise dosing systems, specialized mixing equipment, and thorough process validation.

Colorant systems for medical applications demand particular attention to regulatory compliance and batch-to-batch consistency. Seasoned manufacturers maintain detailed color matching protocols, utilize calibrated spectrophotometers for quality verification, and implement traceability systems that track colorant lot numbers throughout production. This level of control ensures consistent appearance and helps maintain brand recognition across product lines.

Tooling Design and Maintenance Excellence

Precision Mold Engineering

Experienced injection manufacturers excel in mold design optimization, incorporating advanced features such as conformal cooling channels, sophisticated gating systems, and precise ejection mechanisms. Their engineering teams understand how tooling design directly impacts part quality, cycle time, and manufacturing efficiency. Years of experience enable them to anticipate potential molding challenges and incorporate preventive design elements that ensure consistent production.

Advanced mold technologies such as hot runner systems, multi-cavity configurations, and insert molding capabilities require specialized expertise to implement effectively. Veteran manufacturers possess the technical knowledge and equipment necessary to optimize these complex systems, ensuring reliable operation and consistent part quality throughout extended production runs.

Preventive Maintenance and Tool Longevity

Comprehensive mold maintenance programs implemented by experienced manufacturers significantly extend tooling life while maintaining consistent part quality. These programs include regular inspection schedules, preventive component replacement, and detailed maintenance documentation. Proper mold care prevents costly production interruptions and ensures dimensional stability throughout the tool's operational life.

Advanced monitoring systems integrated into modern injection molding equipment provide real-time feedback on mold condition and performance. Experienced manufacturers leverage this data to optimize maintenance schedules, identify wear patterns, and implement corrective actions before quality issues arise. This proactive approach minimizes production disruptions and maintains consistent output quality.

Regulatory Compliance and Documentation Standards

FDA and ISO Certification Management

Experienced injection manufacturers maintain comprehensive quality management systems that comply with stringent medical device regulations including FDA 21 CFR Part 820 and ISO 13485 standards. These systems encompass detailed documentation procedures, change control protocols, and risk management processes that ensure consistent regulatory compliance. Veteran manufacturers understand the critical importance of maintaining accurate records and implementing proper validation procedures for all manufacturing processes.

Regular internal audits and management reviews ensure continuous compliance with evolving regulatory requirements. Experienced manufacturers invest in ongoing training programs that keep their personnel current with changing regulations and industry best practices. This commitment to regulatory excellence provides customers with confidence in product quality and facilitates smooth regulatory approval processes.

Traceability and Batch Documentation

Comprehensive traceability systems implemented by seasoned manufacturers track every aspect of the production process from raw material receipt through final product shipping. These systems maintain detailed records of material lot numbers, processing parameters, quality test results, and environmental conditions throughout manufacturing. Complete traceability enables rapid response to any quality issues and supports regulatory reporting requirements.

Advanced batch documentation systems integrate with manufacturing equipment to automatically capture critical process data, reducing human error and ensuring data integrity. Experienced manufacturers understand the importance of maintaining these records in formats that facilitate regulatory inspections and customer audits while supporting continuous improvement initiatives.

FAQ

How do experienced injection manufacturers ensure consistent part dimensions across large production runs?

Experienced injection manufacturers utilize advanced process monitoring systems that continuously track critical parameters such as injection pressure, temperature profiles, and cycle times. They implement statistical process control methodologies that identify dimensional variations before they exceed acceptable tolerances, enabling real-time adjustments to maintain consistent part geometry throughout extended production runs.

What advantages do veteran injection manufacturers offer for complex medical device geometries?

Veteran manufacturers possess extensive knowledge of advanced molding techniques such as gas-assisted injection, multi-shot molding, and micro-molding processes that enable production of complex geometries with tight tolerances. Their experience with sophisticated tooling designs and specialized processing parameters ensures successful manufacture of intricate medical devices that meet stringent performance requirements.

How do experienced manufacturers handle material validation for new medical device projects?

Experienced injection manufacturers implement comprehensive material validation protocols that include biocompatibility testing, mechanical property verification, and processing parameter optimization. They maintain detailed material databases and work closely with resin suppliers to ensure proper material selection and processing conditions that meet specific medical device requirements and regulatory standards.

What role does process validation play in medical device injection molding?

Process validation represents a critical component of medical device manufacturing that experienced injection manufacturers execute systematically through installation qualification, operational qualification, and performance qualification protocols. These validation activities ensure that manufacturing processes consistently produce devices that meet predetermined specifications and quality requirements, supporting regulatory compliance and patient safety objectives.

Table of Contents

- Advanced Process Control and Quality Assurance Systems

- Material Expertise and Selection Optimization

- Tooling Design and Maintenance Excellence

- Regulatory Compliance and Documentation Standards

-

FAQ

- How do experienced injection manufacturers ensure consistent part dimensions across large production runs?

- What advantages do veteran injection manufacturers offer for complex medical device geometries?

- How do experienced manufacturers handle material validation for new medical device projects?

- What role does process validation play in medical device injection molding?