The Critical Role of Precision in Injection Mold FabricationDefining Precision in Injection Mold ManufacturingAccuracy in mass production of the injection mold is important to measure and repeat. Such precision is important as it would cause sev...

VIEW MORE

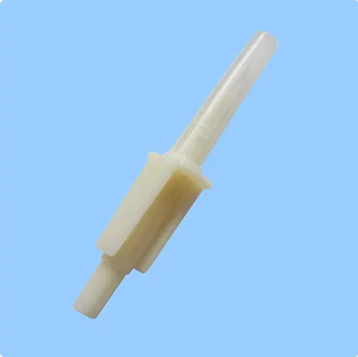

Advanced Material Innovations in 2025 Injection Mold TechnologyBiocompatible Polymers for Medical Applicationsbiocompatibility Polymers that are biocompatible have been invaluable in medicine because of their compatibility with human tissue. The...

VIEW MORE

Understanding Injection Mold Material Composition and Properties The Role of Polymer Structure in Material Performance What are the influences of the polymer chain structure on the performances of materials for the injection molding? The configu...

VIEW MORE

Key Principles for Efficient Injection Mold Design Injection mold design is crucial for manufacturing quality parts efficiently. Understanding the key principles can significantly impact production outcomes. Optimizing Gate Placement and Runner Syst...

VIEW MORE

Defining Standard Medical Components in Surgical Tools Material Consistency and Biocompatibility Consistency of materials and their compatibility with the human body play a major role when making surgical instruments. When manufacturers stick to ma...

VIEW MORE

Essential Roles of Medical Components in Surgical Instruments Precision Engineering in Scalpel and Forceps Design Getting the details right matters a lot when making surgical instruments like scalpels and forceps. Even small changes in how these to...

VIEW MORE

Understanding Biocompatibility in Medical Plastic Injection Molds Defining Biocompatibility for Medical Devices Biocompatibility plays a really important role when creating medical devices. Basically, it means whether a material can work properly w...

VIEW MORE

Understanding SPI Classifications for Medical Injection Molds Getting familiar with SPI classifications ranging from Class 101 all the way down to Class 105 matters a lot when figuring out how long medical injection molds will last and whether they...

VIEW MORE

Key Requirements for Medical-Grade Injection Molds Biocompatibility Standards When it comes to medical grade injection molding, biocompatibility standards matter a lot because they help prevent harmful reactions from happening when materials get in...

VIEW MORE

Understanding OEM Toolingâs Role in Manufacturing Defining OEM Tooling and Its Core Functions OEM tooling plays a really important part in manufacturing processes, helping produce those specialized parts needed across sectors such...

VIEW MORE

Cost Reduction Through OEM Tooling Solutions Lower Production Costs with Custom Tooling Custom tooling helps cut down on production costs because it makes manufacturing processes run smoother. When original equipment manufacturers go with customize...

VIEW MORE

Material Compliance and Biocompatibility in Medical-Grade OEM Molding FDA-Approved Materials for Medical Applications The FDA rules really matter when it comes to keeping materials safe for medical devices. Manufacturers have to stick to strict gui...

VIEW MORE