Key Principles for Efficient Injection Mold Design

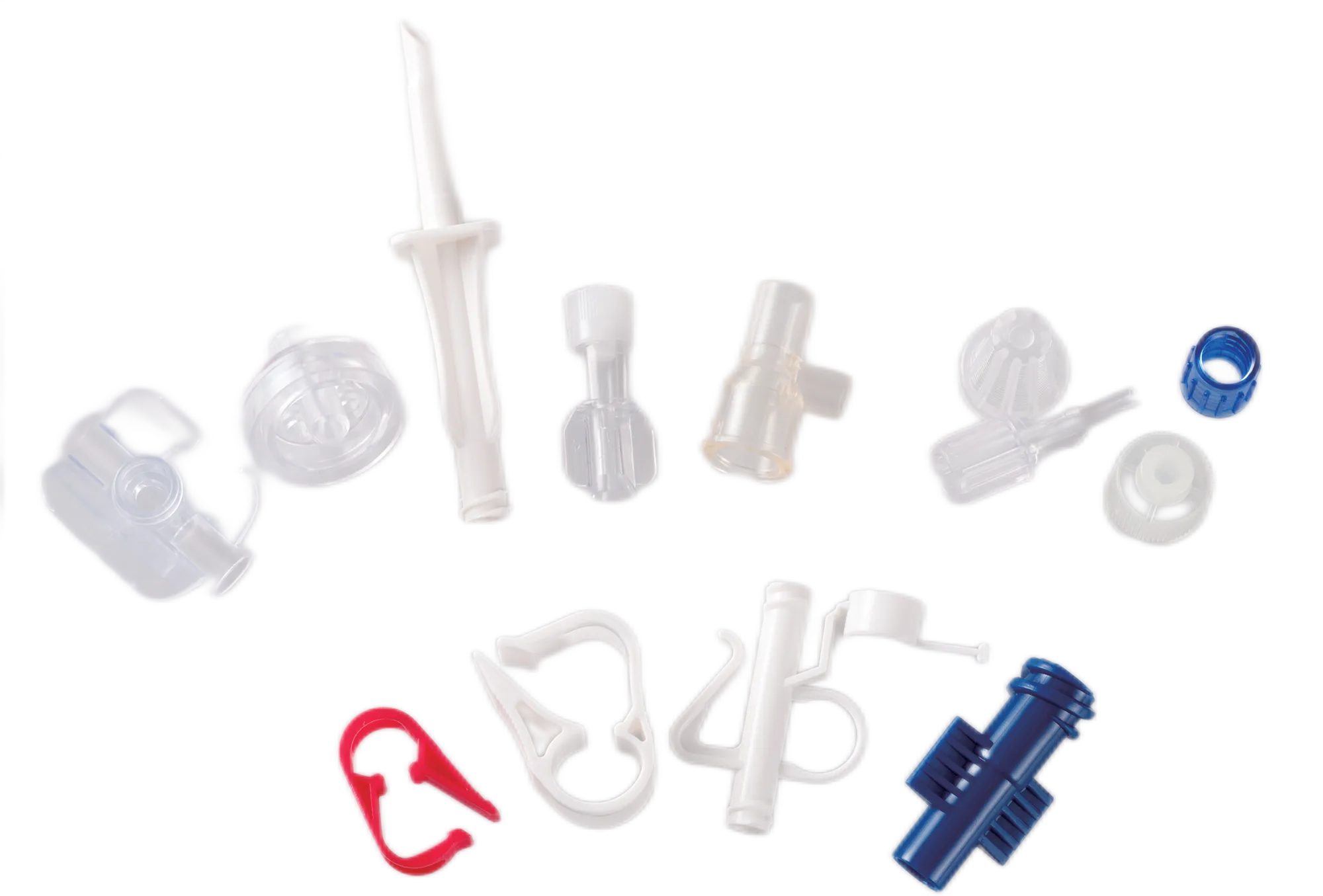

Injection mold design is crucial for manufacturing quality parts efficiently. Understanding the key principles can significantly impact production outcomes.

Optimizing Gate Placement and Runner Systems

Getting gates placed correctly in injection molding makes all the difference when it comes to how molten material fills the mold. Gate position matters because it helps keep material flowing evenly throughout those mold cavities. This even distribution cuts down on internal stresses and lowers chances of getting those pesky defects that weaken parts. There are different types of runner systems out there too. Cold runners save money upfront but often leave behind extra material that needs cleaning up after production. Hot runners maintain plastic in liquid form throughout the process which means better accuracy and less wasted material overall. For manufacturers looking to improve their bottom line while making better products, optimizing gate placement pays off big time. Companies see fewer rejects, stronger finished goods, and ultimately happier customers who don't end up with flawed items.

Ensuring Proper Draft Angles for Seamless Ejection

Draft angles refer to those slight tapers built into parts during design that make it easier to remove them from molds without causing damage. These angles matter because when properly designed, they allow components to slide out smoothly after molding. Without sufficient draft angles, parts tend to stick inside the mold cavity, which makes ejection difficult and often results in surface scratches or warping of the finished product. From a manufacturing standpoint, poor draft angle planning leads to higher expenses across multiple areas. Production lines slow down significantly when workers have to manually pry stuck parts free, while quality control departments spend extra time fixing cosmetic issues caused by improper ejection. Some shops report up to 30% increases in post-processing work just from inadequate draft angles in complex geometries.

Material Selection and Thermal Management in Mold Design

Choosing Mold Materials for Durability and Heat Transfer

Material selection matters a lot when it comes to injection molds, especially regarding how long they'll last and how they handle heat. Most manufacturers stick with either steel or aluminum for their mold bases. Steel stands out because it can take a beating, making it great for production runs that need thousands or even millions of parts. Aluminum brings something different to the table though. The metal conducts heat better than steel, which means parts cool faster in the mold cavity. This translates to shorter cycle times on the shop floor. According to industry reports, premium grade tool steels typically outlast cheaper alternatives by significant margins, sometimes doubling or tripling service life before needing replacement.

When picking out mold materials, folks usually think about how much it will cost, what kind of production run they need, and whether the material can handle the heat requirements for their specific job. Take beryllium copper alloys for instance these fancy materials last longer and manage heat better than standard options, though they definitely hit the wallet harder. The tradeoff between longevity and upfront spending matters a lot when trying to get molds to last through many cycles without breaking down. Smart manufacturers know that getting this balance right means fewer interruptions during production runs and ultimately saves money over time despite the initial investment.

Designing Cooling Channels for Uniform Temperature Control

Good cooling channel design keeps temperatures even across the mold, which stops problems like warping from happening. Cooling channels basically work by getting rid of excess heat while parts are being molded. This not only cuts down on how long each production cycle takes but makes the whole process run smoother overall. When designing these systems, manufacturers need to think about how complicated the mold itself is plus what kind of materials will be used since different substances conduct heat at varying rates. Conformal cooling represents a step forward in this area. Instead of traditional straight lines, these channels follow the actual shape of the mold cavity, allowing for better heat distribution where it matters most. The result? Faster production cycles and fewer defective products coming off the line.

Efficient cooling channel designs impact product consistency and cycle time. Studies show well-designed channels can reduce cycle times, boosting throughput and lowering costs. How do factors like channel size and layout affect results? They play a crucial role in achieving optimal outcomes.

Structural Components to Prevent Production Defects

Incorporating Ribs and Bosses for Enhanced Stability

When it comes to mold design, ribs and bosses aren't just decorative features they actually serve important structural purposes. Ribs basically make parts stiffer so they don't bend or warp under stress, whereas bosses create those little nubs where other components can snap into place. Mold designers really need to think about how these elements work together. Placement matters a lot because if ribs are too close together or bosses are positioned wrong, material might not flow properly during injection. Good designers know that getting the wall thickness right around these areas helps reduce overall part weight without sacrificing durability. The result? Products that hold up better over time, especially when we're talking about things like automotive parts or consumer electronics that see regular use.

Balancing Wall Thickness to Avoid Shrinkage

When walls have uniform thickness throughout, it helps avoid problems such as shrinkage or warping that can ruin products. Uneven cooling rates during manufacturing actually create all sorts of issues because different parts cool at different speeds. This inconsistency weakens the final product's structure. Most experienced manufacturers will tell anyone who listens that keeping wall thickness balanced across the entire piece makes production run much smoother. Looking at what happens on factory floors day after day confirms this connection between consistent wall dimensions and better overall quality results.

Advanced Techniques in Injection Mold Optimization

Leveraging Mold Flow Analysis for Predictive Design

How does mold flow analysis aid design? It's pivotal in identifying potential problems like short shots and warpage. Designers can simulate resin flow and adjust designs early. In automotive, analysis reduces rejection rates by highlighting deformation points for proactive design modifications. This reduces defect-related costs and enhances reliability.

Minimizing Cycle Times Through Efficient Cooling

Efficient cooling affects cycle times, increasing production efficiency. How do innovative cooling technologies help? They regulate temperature and accelerate cycles. Studies show optimized strategies improve cycle times and reduce costs. By leveraging advanced cooling methods, manufacturers ensure quality while maximizing throughput.

FAQ Section

What is injection mold design?

Injection mold design involves creating molds for producing parts through the injection molding process. It includes optimizing designs for efficient material flow and ease of production.

Why is gate placement crucial in injection molding?

Proper gate placement ensures uniform material flow, preventing defects and maintaining structural integrity in molded parts.

What are draft angles, and why are they important?

Draft angles aid in the seamless ejection of parts from molds, preventing damage or deformity during removal.

How does material choice affect mold durability?

Material choice, such as steel or aluminum, impacts mold durability and thermal management, influencing production efficiency and mold lifespan.

Why are cooling channels critical in mold design?

Cooling channels regulate temperature during production, reducing defects like warping and improving cycle times.

How do ribs and bosses enhance part stability?

Ribs and bosses increase structural rigidity and provide attachment points, reinforcing molded parts while keeping weight low.

What is mold flow analysis?

Mold flow analysis is a predictive tool for simulating resin flow in molds, enabling designers to optimize designs and reduce defects.

Table of Contents

- Key Principles for Efficient Injection Mold Design

-

Material Selection and Thermal Management in Mold Design

- Choosing Mold Materials for Durability and Heat Transfer

- Designing Cooling Channels for Uniform Temperature Control

- Structural Components to Prevent Production Defects

- Incorporating Ribs and Bosses for Enhanced Stability

- Balancing Wall Thickness to Avoid Shrinkage

- Advanced Techniques in Injection Mold Optimization

- Leveraging Mold Flow Analysis for Predictive Design

- Minimizing Cycle Times Through Efficient Cooling

-

FAQ Section

- What is injection mold design?

- Why is gate placement crucial in injection molding?

- What are draft angles, and why are they important?

- How does material choice affect mold durability?

- Why are cooling channels critical in mold design?

- How do ribs and bosses enhance part stability?

- What is mold flow analysis?