Selecting the appropriate medical-grade tubing and catheters for complex surgical procedures represents one of the most critical decisions healthcare professionals make in their practice. The complexity of modern surgical interventions demands materials that meet stringent biocompatibility standards while maintaining optimal performance characteristics. Medical-grade tubing serves as the foundation for numerous medical devices, from simple drainage systems to sophisticated cardiovascular catheters used in life-saving procedures. Understanding the fundamental properties and selection criteria for these materials ensures patient safety and procedural success.

Understanding Medical-Grade Material Classifications

Regulatory Standards and Certifications

Medical-grade tubing must comply with rigorous regulatory standards established by organizations such as the FDA, ISO, and USP. These standards define the biocompatibility requirements, chemical composition limits, and physical properties necessary for safe patient contact. ISO 10993 series specifically addresses biological evaluation of medical devices, providing comprehensive testing protocols for cytotoxicity, sensitization, and systemic toxicity. Healthcare facilities must verify that their selected medical-grade tubing carries appropriate certifications from recognized testing laboratories.

The United States Pharmacopeia Class VI certification represents the gold standard for plastic materials used in medical applications. This classification ensures that materials have undergone extensive biological testing and demonstrate minimal tissue reaction when implanted or used in direct patient contact. Medical-grade tubing bearing this certification provides surgeons with confidence in material safety and performance consistency across diverse surgical environments.

Material Composition and Properties

Different surgical applications require specific material properties that directly impact patient outcomes and procedural efficiency. Silicone-based medical-grade tubing offers exceptional biocompatibility and flexibility, making it ideal for long-term implantation and delicate tissue contact. Polyurethane materials provide superior tensile strength and puncture resistance, essential for high-pressure applications and complex catheter designs used in interventional procedures.

Thermoplastic elastomers represent an emerging category of medical-grade tubing materials that combine the processing advantages of thermoplastics with the performance characteristics of elastomers. These materials offer excellent chemical resistance and can be precisely engineered to meet specific durometer requirements for different surgical applications. The selection process must carefully evaluate material properties against the specific demands of each surgical procedure.

Critical Selection Parameters for Surgical Applications

Dimensional Specifications and Tolerances

Precise dimensional control in medical-grade tubing directly impacts the performance of surgical instruments and patient safety outcomes. Wall thickness uniformity ensures consistent flow characteristics and prevents unexpected failures during critical procedures. Inner diameter tolerances must be maintained within strict limits to ensure proper fit with connectors, guidewires, and other medical components used throughout complex surgical interventions.

The relationship between outer diameter and wall thickness determines the mechanical properties of medical-grade tubing under various loading conditions. Thin-walled configurations maximize internal lumen diameter while maintaining adequate structural integrity for navigation through tortuous anatomical pathways. Surgeons must consider these dimensional relationships when selecting tubing for specific procedural requirements and patient anatomical variations.

Mechanical Performance Requirements

Tensile strength and elongation characteristics of medical-grade tubing determine its ability to withstand the mechanical stresses encountered during surgical procedures. High-stress applications, such as balloon catheter inflation and endoscopic instrument manipulation, require materials with superior mechanical properties to prevent catastrophic failure. The elastic modulus of medical-grade tubing affects its flexibility and handling characteristics, directly impacting surgeon dexterity and patient comfort during procedures.

Fatigue resistance becomes particularly important for medical-grade tubing used in repetitive motion applications or long-duration procedures. Materials must maintain their mechanical properties throughout extended use cycles without developing stress fractures or performance degradation. Testing protocols should evaluate cyclic loading performance under conditions that simulate actual surgical use to ensure reliable material selection.

Biocompatibility and Safety Considerations

Cytotoxicity and Tissue Response

The biological response to medical-grade tubing materials represents a fundamental safety consideration that impacts both immediate and long-term patient outcomes. Cytotoxicity testing evaluates the potential for materials to release harmful substances that could damage surrounding tissues or interfere with cellular function. Medical-grade tubing must demonstrate minimal cytotoxic response under standardized testing conditions that simulate clinical use environments.

Inflammatory response assessment provides critical information about tissue compatibility for medical-grade tubing intended for implantation or extended patient contact. Materials that trigger excessive inflammatory responses can lead to complications such as tissue encapsulation, infection, or device failure. Comprehensive biocompatibility evaluation includes assessment of acute and chronic inflammatory responses using standardized animal models and in vitro testing protocols.

Sterilization Compatibility

Medical-grade tubing must maintain its physical and chemical properties throughout sterilization processes commonly used in healthcare facilities. Steam sterilization, ethylene oxide treatment, and gamma irradiation each impose specific requirements on material selection and processing parameters. The choice of sterilization method can significantly impact the performance characteristics of medical-grade tubing, requiring careful evaluation during the selection process.

Repeated sterilization cycles present additional challenges for medical-grade tubing used in reusable medical devices. Materials must demonstrate stability under multiple sterilization exposures without significant degradation of mechanical properties or biocompatibility characteristics. Validation testing should evaluate the cumulative effects of sterilization on medical-grade tubing performance to establish appropriate reuse limitations and replacement schedules.

Application-Specific Selection Guidelines

Cardiovascular Procedures

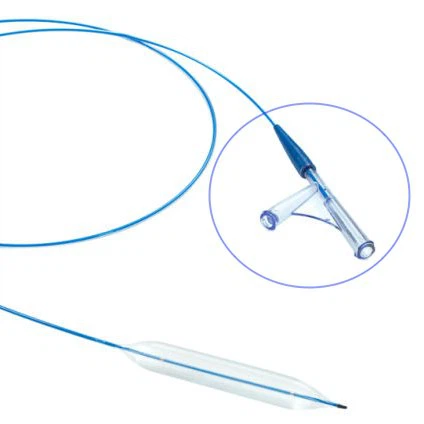

Cardiovascular applications place unique demands on medical-grade tubing performance, requiring materials that can withstand high pressures while maintaining flexibility for navigation through complex vascular anatomy. Balloon catheter applications require medical-grade tubing with exceptional burst strength and fatigue resistance to ensure safe inflation and deflation cycles. The selection process must consider the specific pressure requirements and cyclic loading conditions encountered in different cardiovascular procedures.

Thromboresistance represents a critical property for medical-grade tubing used in cardiovascular applications where blood contact is unavoidable. Surface modifications and material selection can significantly impact the thrombogenic potential of medical devices, directly affecting patient safety and procedural success rates. Healthcare facilities should evaluate the thromboresistance characteristics of medical-grade tubing through appropriate testing protocols and clinical evidence.

Minimally Invasive Surgery

Minimally invasive surgical procedures require medical-grade tubing with exceptional flexibility and trackability to navigate through small incisions and confined anatomical spaces. The balance between flexibility and pushability becomes critical for successful device delivery and manipulation during complex procedures. Medical-grade tubing selection must consider the specific torque transmission requirements and bend radius limitations imposed by minimally invasive techniques.

Radiopacity characteristics of medical-grade tubing play an important role in minimally invasive procedures where fluoroscopic guidance is essential. Materials with appropriate radiopaque additives enable real-time visualization during device placement and manipulation, enhancing procedural safety and accuracy. The selection process should evaluate radiopacity requirements against other performance criteria to achieve optimal balance for specific surgical applications.

Quality Assurance and Testing Protocols

Manufacturing Process Validation

Consistent quality in medical-grade tubing requires robust manufacturing process validation that ensures reproducible material properties and dimensional characteristics. Statistical process control methods should be implemented throughout the production cycle to monitor critical parameters and detect variations that could impact product performance. Healthcare facilities should evaluate the manufacturing quality systems of medical-grade tubing suppliers to ensure compliance with appropriate regulatory standards.

Traceability systems for medical-grade tubing manufacturing enable rapid response to quality issues and facilitate continuous improvement initiatives. Comprehensive documentation of raw materials, processing parameters, and quality control results provides the foundation for effective risk management and regulatory compliance. The selection process should prioritize suppliers with demonstrated commitment to quality assurance and continuous improvement in medical-grade tubing production.

Performance Testing Requirements

Comprehensive performance testing of medical-grade tubing should encompass both standard material property evaluations and application-specific functional assessments. Tensile testing, durometer measurement, and dimensional verification provide baseline material characterization data necessary for informed selection decisions. Additional testing protocols should evaluate performance under conditions that simulate actual surgical use, including temperature variations, chemical exposure, and mechanical loading cycles.

Accelerated aging studies provide valuable insights into the long-term stability and performance of medical-grade tubing materials under storage and use conditions. These studies can reveal potential degradation mechanisms and help establish appropriate shelf life limitations for medical devices incorporating these materials. Healthcare facilities should review aging study data when selecting medical-grade tubing for applications requiring extended storage or implantation periods.

Cost-Effectiveness and Supply Chain Considerations

Total Cost of Ownership Analysis

Effective selection of medical-grade tubing requires comprehensive evaluation of total cost of ownership beyond initial material prices. Factors such as processing complexity, quality control requirements, and potential failure costs must be considered in the economic analysis. Higher-quality medical-grade tubing materials may justify premium pricing through reduced processing time, lower rejection rates, and enhanced patient safety outcomes.

Long-term supply availability and price stability represent important considerations for medical-grade tubing selection in healthcare facilities with high-volume requirements. Suppliers with diversified manufacturing capabilities and robust supply chain management systems can provide greater assurance of consistent availability and pricing for medical-grade tubing materials. The selection process should evaluate supplier financial stability and commitment to the medical device market segment.

Regulatory Compliance Costs

Regulatory compliance requirements for medical-grade tubing can significantly impact total project costs through testing, documentation, and approval processes. Materials with established regulatory approval histories may offer cost advantages through reduced validation requirements and shorter approval timelines. Healthcare facilities should evaluate the regulatory status of medical-grade tubing materials in relevant markets to optimize compliance costs and time-to-market considerations.

Change control procedures for medical-grade tubing modifications require careful cost-benefit analysis to balance performance improvements against regulatory compliance expenses. Suppliers with robust change control systems and regulatory expertise can help minimize the impact of necessary modifications on project timelines and costs. The selection process should consider supplier capabilities in managing regulatory requirements for medical-grade tubing applications.

FAQ

What are the most important biocompatibility standards for medical-grade tubing selection?

The most critical biocompatibility standards for medical-grade tubing include ISO 10993 series for biological evaluation of medical devices and USP Class VI certification for plastic materials. These standards provide comprehensive testing protocols for cytotoxicity, sensitization, irritation, and systemic toxicity. Medical-grade tubing should also comply with FDA guidance documents specific to the intended application, such as cardiovascular or neurological devices, to ensure appropriate safety margins for patient contact.

How do sterilization methods affect medical-grade tubing performance?

Different sterilization methods can significantly impact the physical and chemical properties of medical-grade tubing materials. Steam sterilization may cause dimensional changes in thermoplastic materials, while ethylene oxide treatment requires adequate degassing time to eliminate residual chemicals. Gamma irradiation can cause chain scission or cross-linking in polymer materials, affecting mechanical properties. Medical-grade tubing selection must consider the intended sterilization method and validate material stability under those specific conditions.

What factors determine the appropriate wall thickness for medical-grade tubing?

Wall thickness selection for medical-grade tubing depends on multiple factors including internal pressure requirements, flexibility needs, and manufacturing constraints. Thicker walls provide greater burst strength and structural integrity but reduce internal diameter and increase stiffness. The application requirements for medical-grade tubing must be carefully balanced against material properties to achieve optimal performance. Finite element analysis can help optimize wall thickness for specific loading conditions and performance requirements.

How should healthcare facilities evaluate suppliers of medical-grade tubing?

Healthcare facilities should evaluate medical-grade tubing suppliers based on regulatory compliance history, quality management systems, technical capabilities, and supply chain reliability. Key evaluation criteria include ISO 13485 certification, FDA registration status, documented quality control procedures, and evidence of continuous improvement programs. Medical-grade tubing suppliers should demonstrate expertise in medical device regulations and provide comprehensive technical support throughout the product development and commercialization process.

Table of Contents

- Understanding Medical-Grade Material Classifications

- Critical Selection Parameters for Surgical Applications

- Biocompatibility and Safety Considerations

- Application-Specific Selection Guidelines

- Quality Assurance and Testing Protocols

- Cost-Effectiveness and Supply Chain Considerations

-

FAQ

- What are the most important biocompatibility standards for medical-grade tubing selection?

- How do sterilization methods affect medical-grade tubing performance?

- What factors determine the appropriate wall thickness for medical-grade tubing?

- How should healthcare facilities evaluate suppliers of medical-grade tubing?