Understanding Injection Molding Cycle Time Components

Getting the injection molding cycle time right matters a lot in manufacturing operations. There are basically four main steps involved: injection, packing, cooling, and finally ejection. Knowing how each works helps manufacturers get better results from their production runs. When talking about injection, hot plastic gets forced into the mold cavity. Though short in duration, this step really impacts whether parts come out consistent and free from defects. Next comes packing, where extra material fills any gaps caused by shrinkage during cooling. How long this takes depends heavily on what kind of plastic they're working with and how the mold was designed. Cooling takes up most of the total time though. Proper cooling ensures the plastic hardens correctly so it won't warp when ejected later. Smart shops often tweak water line placement or switch to different mold materials just to shave minutes off this part of the process. Last but not least is ejection itself. Once everything has cooled down enough, mechanisms push the finished product out of the mold. Faster ejection means more parts per hour overall. Factories that understand all these details tend to run smoother and waste less money over time.

Why Cycle Time Directly Affects Production Costs

How long it takes to complete a production cycle has a big impact on overall costs and how efficiently operations run. When companies manage to cut down on cycle time, they typically see reduced energy consumption while getting more output from each machine cycle. The financial benefits are pretty straightforward really. Shorter cycles mean machines aren't running as long between products, which saves money on power bills and keeps equipment working harder for longer periods. Getting those cycle times right also means factories can produce more items within any set timeframe. This matters because manufacturers need to respond quickly when customer demand changes or competitors enter the market. For this reason, finding ways to optimize cycle times remains critical for businesses looking to boost their production capabilities without breaking the bank while staying competitive against other players in the industry.

Wall Thickness and Material Selection

The thickness of walls makes a big difference during the cooling stage in injection molding processes. When walls are thicker, they take much longer to cool down, which means longer overall cycle times and slower production rates. What kind of material gets used matters too when trying to cut down on those cycle times. Certain plastics just cool faster than others. Take amorphous polymers for example these tend to solidify quicker compared to their semi crystalline counterparts, sometimes cutting several minutes off each cycle. So manufacturers who want both speed and quality need to carefully pick their materials and keep wall thickness within reasonable limits. Getting this balance right helps maintain production speeds without compromising the final product's structural integrity.

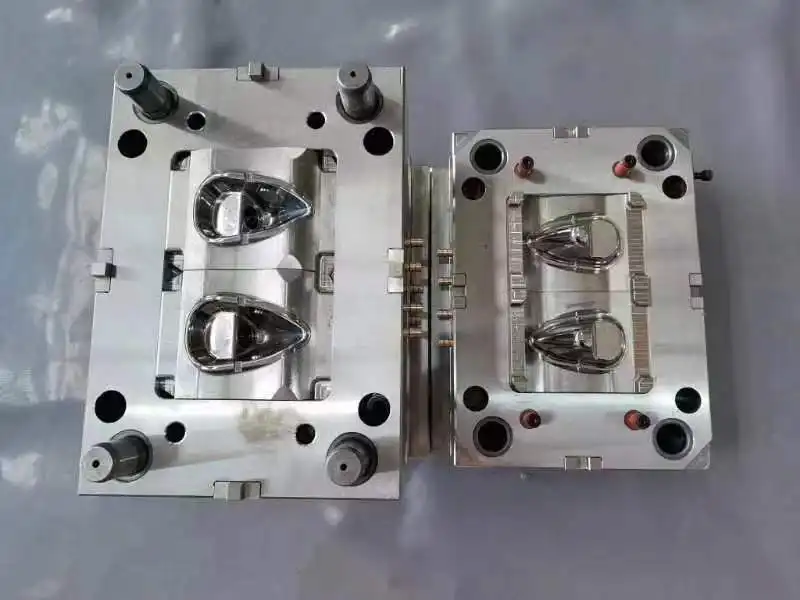

Mold Design and Cooling Efficiency

Mold design greatly influences heat transfer efficiency, affecting cycle time optimization. Well-designed molds facilitate swift heat dissipation, shortening the cooling phase.Incorporating proper cooling channels prevents hotspots, ensuring uniform solidification.Investing in innovative mold design is crucial for manufacturers aiming to optimize injection molding cycles.

Process Adjustments for Faster Cycle Times

Optimizing Fill/Pack and Cooling Phases

Adjusting the fill and pack phases in injection molding is crucial for achieving shorter cycle times. Modifying material injection speed is essential to avoid defects like burns or short shots caused by improper cooling.Adjustments in pressure and temperature settings can balance rapid cooling and ensure high-quality finishes.

Reducing Hold Time Without Compromising Quality

Reducing hold time is effective in decreasing cycle times without compromising component quality. Strategies include adjusting the gate seal time to prevent material backflow while maintaining integrity during cooling.Gradual hold time reductions maintain product quality while enhancing production efficiencies.

Advanced Techniques for Cycle Time Reduction

Implementing Conformal Cooling Systems

Conformal cooling systems are a breakthrough in reducing cycle time. These systems enhance heat extraction efficiency, resulting in faster cooling times and reduced cycles.Advanced 3D printing technologies facilitate the creation of complex cooling channels, boosting mold cooling efficiency.

Leveraging Hot Runner Technology

Hot runner technologies keep plastic in a molten state within the manifold, reducing cooling time and making the molding process more efficient.Unlike cold runner systems that require plastic solidification time, hot runners eliminate this phase, accelerating cycle completion.

Monitoring and Continuous Improvement

Using Data Analytics for Process Refinement

Data analytics are vital for refining injection molding processes. Utilizing advanced analytics tools allows for continuous cycle time monitoring, providing valuable insights.Analyzing data can identify trends and inefficiencies, leading to substantial process improvements.

Preventative Maintenance Strategies

Preventative maintenance ensures operational efficiency and optimal cycle times. Regular maintenance routines prevent unexpected downtimes and uphold peak machine performance.

Structured schedules enhance machine functionality, contributing positively to cycle time reduction.

FAQ Section

What are the key phases in the injection molding process?

The injection molding process is structured into four primary phases: injection, packing, cooling, and ejection. Each phase plays a vital role in determining overall efficiency and cycle time.

How does cycle time affect production costs?

Cycle time significantly impacts production costs by affecting operational efficiency. Shorter cycle times result in lower energy consumption and increased throughput, which reduces costs and enhances market responsiveness.

Why is wall thickness important in injection molding?

Wall thickness directly impacts the cooling duration in the molding cycle. Thicker walls require longer cooling times, affecting overall cycle time and production efficiency.

What role does mold design play in cycle time optimization?

Mold design is crucial for effective heat transfer and cycle time optimization. Proper cooling channels and mold materials can significantly improve cooling efficiency and shorten cycle times.

How can data analytics improve injection molding processes?

Data analytics help identify process inefficiencies and trends. By analyzing cycle time data, companies can make informed decisions to enhance their operations and reduce cycle time effectively.

Table of Contents

- Understanding Injection Molding Cycle Time Components

- Why Cycle Time Directly Affects Production Costs

- Wall Thickness and Material Selection

- Mold Design and Cooling Efficiency

- Process Adjustments for Faster Cycle Times

- Advanced Techniques for Cycle Time Reduction

- Monitoring and Continuous Improvement

- FAQ Section