Sự Tiến Hóa Của Sản Xuất Hiện Đại Thông Qua Các Giải Pháp Ép Phun Theo Đơn Đặt Hàng

Trong bối cảnh sản xuất tiên tiến ngày nay, độ chính xác và tính nhất quán là yếu tố hàng đầu. Ép phun theo đơn đặt hàng ép nhựa đã nổi lên như một công nghệ nền tảng, cho phép các nhà sản xuất tạo ra các bộ phận phức tạp, chất lượng cao với độ chính xác chưa từng có. Quy trình tinh vi này kết hợp giữa sự xuất sắc trong kỹ thuật và khoa học vật liệu để cung cấp các thành phần đáp ứng đúng thông số kỹ thuật đồng thời duy trì hiệu quả về chi phí ở quy mô lớn.

Ngành công nghiệp sản xuất đã chứng kiến sự chuyển đổi đáng kể trong vài thập kỷ gần đây, chủ yếu nhờ vào các đột phá trong kỹ thuật đúc phun tùy chỉnh. Từ thiết bị y tế đến các bộ phận hàng không vũ trụ, phương pháp sản xuất linh hoạt này tiếp tục mở rộng giới hạn của những gì có thể đạt được trong sản xuất chi tiết chính xác. Khi các ngành công nghiệp đòi hỏi độ dung sai ngày càng khắt khe và hình dạng phức tạp hơn, đúc phun tùy chỉnh nổi bật như giải pháp hàng đầu cho doanh nghiệp tìm kiếm chất lượng và độ nhất quán vượt trội.

Hiểu về Quy trình Đúc Phun Tùy Chỉnh

Các Thành Phần Cốt Lõi Và Công Nghệ

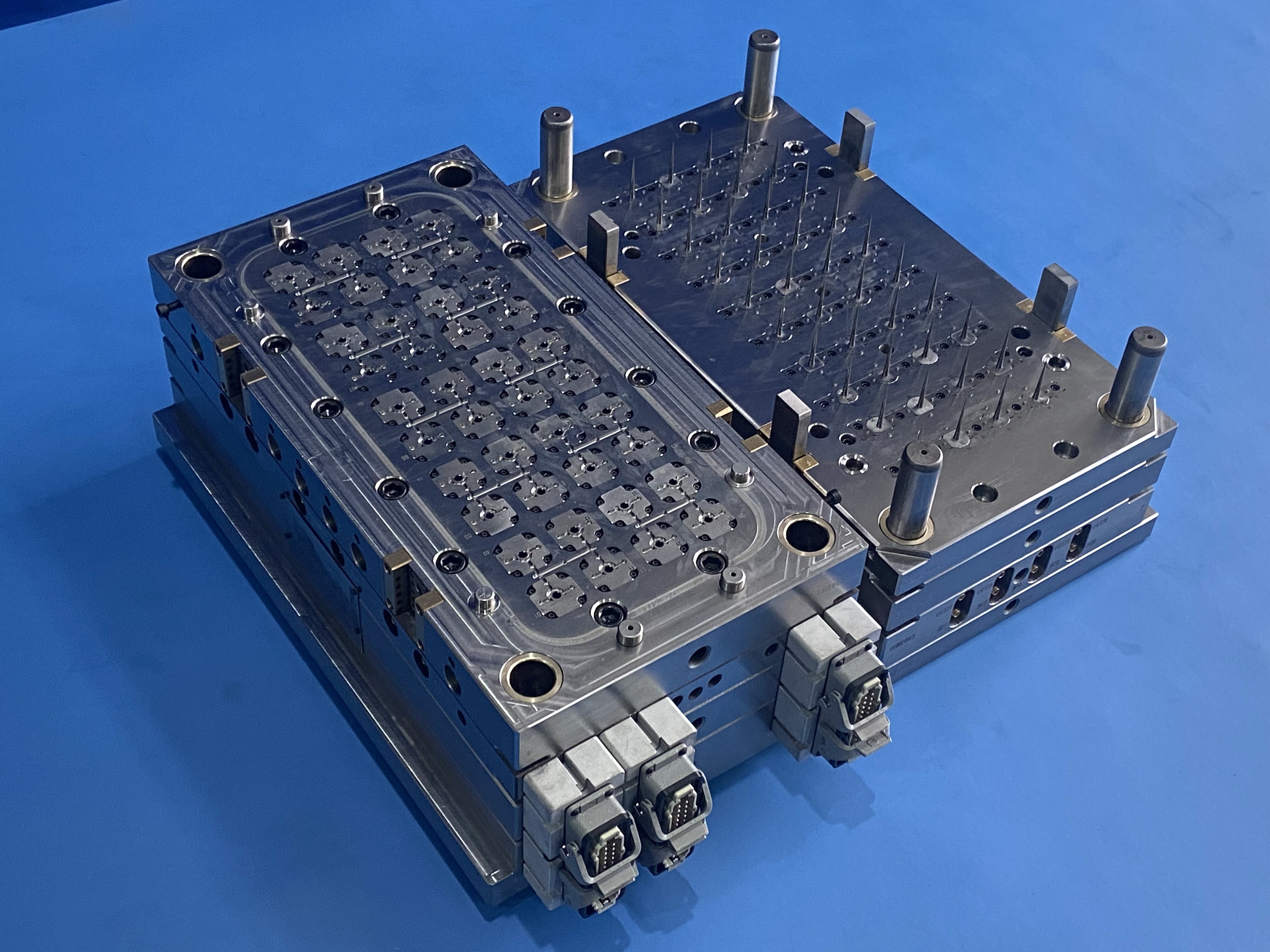

Về bản chất, đúc phun tùy chỉnh bao gồm một quy trình được tổ chức cẩn thận, trong đó vật liệu nóng chảy được tiêm vào buồng khuôn được thiết kế chính xác. Các thiết bị được sử dụng trong các cơ sở đúc phun tùy chỉnh hiện đại bao gồm các đơn vị phun tinh vi, hệ thống kẹp tự động và cơ chế làm mát tiên tiến. Những thành phần này phối hợp nhịp nhàng để đảm bảo mỗi chi tiết đều đáp ứng đúng thông số kỹ thuật.

Quy trình bắt đầu bằng việc lựa chọn vật liệu, trong đó các kỹ sư chọn từ một loạt các polymer và chất phụ gia để phù hợp với yêu cầu ứng dụng cụ thể. Vật liệu sau đó được đun nóng đến nhiệt độ xử lý tối ưu trước khi được tiêm vào khuôn dưới các thông số áp suất và tốc độ được kiểm soát cẩn thận. Mức độ kiểm soát này đảm bảo tính nhất quán trong các lần sản xuất, dù đang sản xuất hàng trăm hay hàng triệu chi tiết.

Hệ thống kiểm soát và giám sát tiên tiến

Các máy ép phun tùy chỉnh hiện đại tích hợp các hệ thống điều khiển tiên tiến nhất, giám sát mọi khía cạnh của quá trình sản xuất. Từ nhiệt độ nóng chảy đến áp suất tiêm, các hệ thống này duy trì sự kiểm soát chặt chẽ đối với các thông số quan trọng. Khả năng giám sát và điều chỉnh theo thời gian thực đảm bảo rằng mỗi chu kỳ sản xuất đều tạo ra các chi tiết đạt tiêu chuẩn chất lượng nghiêm ngặt.

Việc tích hợp các cảm biến thông minh và phân tích dữ liệu cho phép các nhà sản xuất phát hiện và khắc phục các sự cố tiềm ẩn trước khi chúng ảnh hưởng đến chất lượng sản phẩm. Cách tiếp cận chủ động trong kiểm soát chất lượng này đã cách mạng hóa ngành công nghiệp, khiến gia công ép phun tùy chỉnh trở thành một trong những quy trình sản xuất đáng tin cậy nhất hiện nay.

Lựa Chọn Vật Liệu Và Các Yếu Tố Kỹ Thuật Liên Quan

Tính chất và Hiệu suất của Polyme

Thành công của mọi dự án ép phun tùy chỉnh đều bắt đầu từ việc lựa chọn vật liệu phù hợp. Các kỹ sư phải cân nhắc nhiều yếu tố khác nhau bao gồm tính chất cơ học, khả năng chống hóa chất, độ ổn định nhiệt và hiệu quả về chi phí. Các cơ sở sản xuất hiện đại duy trì thư viện vật liệu phong phú, cho phép họ lựa chọn công thức polyme tối ưu phù hợp với yêu cầu ứng dụng cụ thể.

Các loại nhựa nhiệt dẻo kỹ thuật cao, như polyetheretherketone (PEEK) và polymer tinh thể lỏng (LCP), đã mở rộng khả năng của công nghệ đúc phun tùy chỉnh. Những vật liệu này mang lại độ bền vượt trội, khả năng chịu nhiệt và độ ổn định kích thước tốt, làm cho chúng trở nên lý tưởng cho các ứng dụng đòi hỏi khắt khe trong ngành hàng không vũ trụ, ô tô và y tế.

Tối ưu hóa Thiết kế cho Sản xuất

Việc đúc phun tùy chỉnh thành công đòi hỏi sự chú ý cẩn thận đến các nguyên tắc thiết kế nhằm tối ưu hóa khả năng sản xuất chi tiết. Các kỹ sư phải xem xét các yếu tố như độ đồng đều chiều dày thành, góc thoát khuôn và vị trí cổng phun để đảm bảo dòng chảy vật liệu phù hợp và chất lượng chi tiết. Phần mềm thiết kế hỗ trợ bằng máy tính (CAD) và mô phỏng tiên tiến giúp xác định các vấn đề tiềm ẩn trước khi bắt đầu chế tạo khuôn.

Giai đoạn thiết kế cũng bao gồm các yếu tố liên quan đến việc lắp ráp chi tiết, các thao tác phụ trợ và yêu cầu sử dụng cuối cùng. Bằng cách tích hợp những yếu tố này ngay từ đầu quá trình thiết kế, các nhà sản xuất có thể tối ưu hóa cả hiệu suất của chi tiết lẫn hiệu quả sản xuất, từ đó mang lại các giải pháp tiết kiệm chi phí hơn cho khách hàng.

Đảm bảo chất lượng trong các hoạt động đúc theo yêu cầu

Các phương pháp và công nghệ kiểm tra

Đảm bảo chất lượng trong quy trình đúc phun tùy chỉnh bao gồm một loạt các phương pháp và công nghệ kiểm tra toàn diện. Các hệ thống đo lường tiên tiến, bao gồm máy đo ba chiều (CMM) và thiết bị quét quang học, cho phép xác minh chính xác kích thước của các chi tiết đúc. Những hệ thống này có thể phát hiện các sai lệch nhỏ tới vài micron, đảm bảo tính nhất quán trong suốt quá trình sản xuất.

Các phương pháp kiểm tra không phá hủy, như kiểm tra bằng tia X và quét siêu âm, cho phép các nhà sản xuất xác minh các đặc điểm bên trong và phát hiện các khuyết tật tiềm ẩn mà không làm hư hại các bộ phận. Khả năng này đặc biệt có giá trị trong các ứng dụng y tế và hàng không vũ trụ, nơi độ nguyên vẹn của bộ phận là yếu tố then chốt.

Tài liệu và Khả năng truy xuất nguồn gốc

Các cơ sở sản xuất khuôn ép phun tùy chỉnh hiện đại duy trì hệ thống tài liệu chặt chẽ để đảm bảo khả năng truy xuất nguồn gốc trong suốt quá trình sản xuất. Từ chứng chỉ vật liệu thô đến các thông số quy trình và kết quả kiểm tra, mọi khía cạnh của sản xuất đều được ghi nhận và lưu trữ. Tài liệu toàn diện này hỗ trợ việc chứng nhận chất lượng và tuân thủ quy định, đồng thời cung cấp dữ liệu hữu ích cho việc cải tiến liên tục quy trình.

Các hệ thống thực thi sản xuất tiên tiến (MES) cho phép theo dõi thời gian thực các chỉ số sản xuất và dữ liệu chất lượng. Thông tin này giúp các nhà sản xuất tối ưu hóa quy trình, giảm lãng phí và duy trì mức chất lượng ổn định qua nhiều đợt sản xuất.

Các Xét đến Chi phí và Lợi ích Kinh tế

Chi phí ban đầu và giá trị dài hạn

Mặc dù chi phí ban đầu cho khuôn đúc phun tùy chỉnh có vẻ đáng kể, nhưng lợi ích kinh tế dài hạn thường vượt trội hơn khoản đầu tư ban đầu. Các khuôn chất lượng cao có thể sản xuất hàng triệu bộ phận với chất lượng ổn định, dẫn đến chi phí trên mỗi bộ phận rất thấp khi được phân bổ trong suốt quá trình sản xuất. Ngoài ra, khả năng tạo ra các hình dạng phức tạp trong một thao tác duy nhất thường loại bỏ nhu cầu thực hiện các công đoạn phụ tốn kém.

Khả năng tự động hóa của các hệ thống đúc phun tùy chỉnh hiện đại còn làm tăng hiệu quả kinh tế bằng cách giảm chi phí lao động và tối thiểu hóa sai sót do con người. Những hệ thống này có thể vận hành liên tục với sự can thiệp tối thiểu của người vận hành, từ đó tối đa hóa năng suất và tỷ suất hoàn vốn.

Hiệu quả sản xuất và giảm thiểu chất thải

Gia công khuôn ép phun tùy chỉnh mang lại nhiều lợi thế đáng kể về hiệu quả sử dụng nguyên vật liệu và giảm thiểu chất thải. Các hệ thống điều khiển quá trình tiên tiến cùng thiết kế khuôn được tối ưu hóa giúp giảm thiểu lượng vật liệu phế thải, trong khi các hệ thống tái chế cho phép thu hồi và tái sử dụng phế liệu từ quá trình sản xuất. Những cải tiến về hiệu suất này góp phần vào cả tính bền vững môi trường lẫn hiệu quả kinh tế.

Khả năng sản xuất các chi tiết với yêu cầu gia công sau rất ít cũng giúp giảm chi phí sản xuất tổng thể. Khi được thiết kế và thực hiện đúng cách, các chi tiết đúc ép phun tùy chỉnh sẽ ra khỏi khuôn ở trạng thái sẵn sàng sử dụng hoặc lắp ráp, từ đó loại bỏ các công đoạn hoàn thiện tốn kém.

Các câu hỏi thường gặp

Thời gian sản xuất điển hình cho các chi tiết ép phun tùy chỉnh là bao lâu?

Thời gian sản xuất các bộ phận đúc phun tùy chỉnh thay đổi tùy theo độ phức tạp của dự án, yêu cầu thiết kế khuôn và khối lượng sản xuất. Những khuôn đơn giản có thể hoàn thành trong 4-6 tuần, trong khi các dự án phức tạp hơn có thể mất từ 8-12 tuần hoặc lâu hơn. Sau khi hoàn thành khuôn, quá trình sản xuất thường có thể bắt đầu trong vòng vài ngày kể từ khi đặt hàng.

Đúc phun tùy chỉnh so với các phương pháp sản xuất khác như thế nào?

Đúc phun tùy chỉnh mang lại độ nhất quán, khả năng mở rộng và hiệu quả chi phí vượt trội so với nhiều phương pháp sản xuất khác. Trong khi in 3D có thể phù hợp hơn cho mẫu thử và sản xuất số lượng thấp, thì đúc phun tùy chỉnh nổi bật trong việc sản xuất số lượng lớn các bộ phận chính xác, phức tạp với độ hoàn thiện bề mặt và tính chất cơ học tốt.

Số lượng tối thiểu cần thiết để đúc phun tùy chỉnh là bao nhiêu?

Số lượng đặt hàng tối thiểu thay đổi tùy theo kích thước, độ phức tạp của chi tiết và chi phí khuôn mẫu. Trong khi một số dự án có thể yêu cầu hàng nghìn chi tiết để đảm bảo hiệu quả kinh tế, thì các kỹ thuật sản xuất tiên tiến và dụng cụ nhiều khoang có thể giúp các lô sản xuất nhỏ trở nên tiết kiệm chi phí hơn. Các nhà sản xuất thường làm việc cùng khách hàng để xác định số lượng sản xuất tối ưu dựa trên các yêu cầu cụ thể của từng dự án.