Đổi Mới Sản Xuất Thông Qua Ép Phun Theo Yêu Cầu

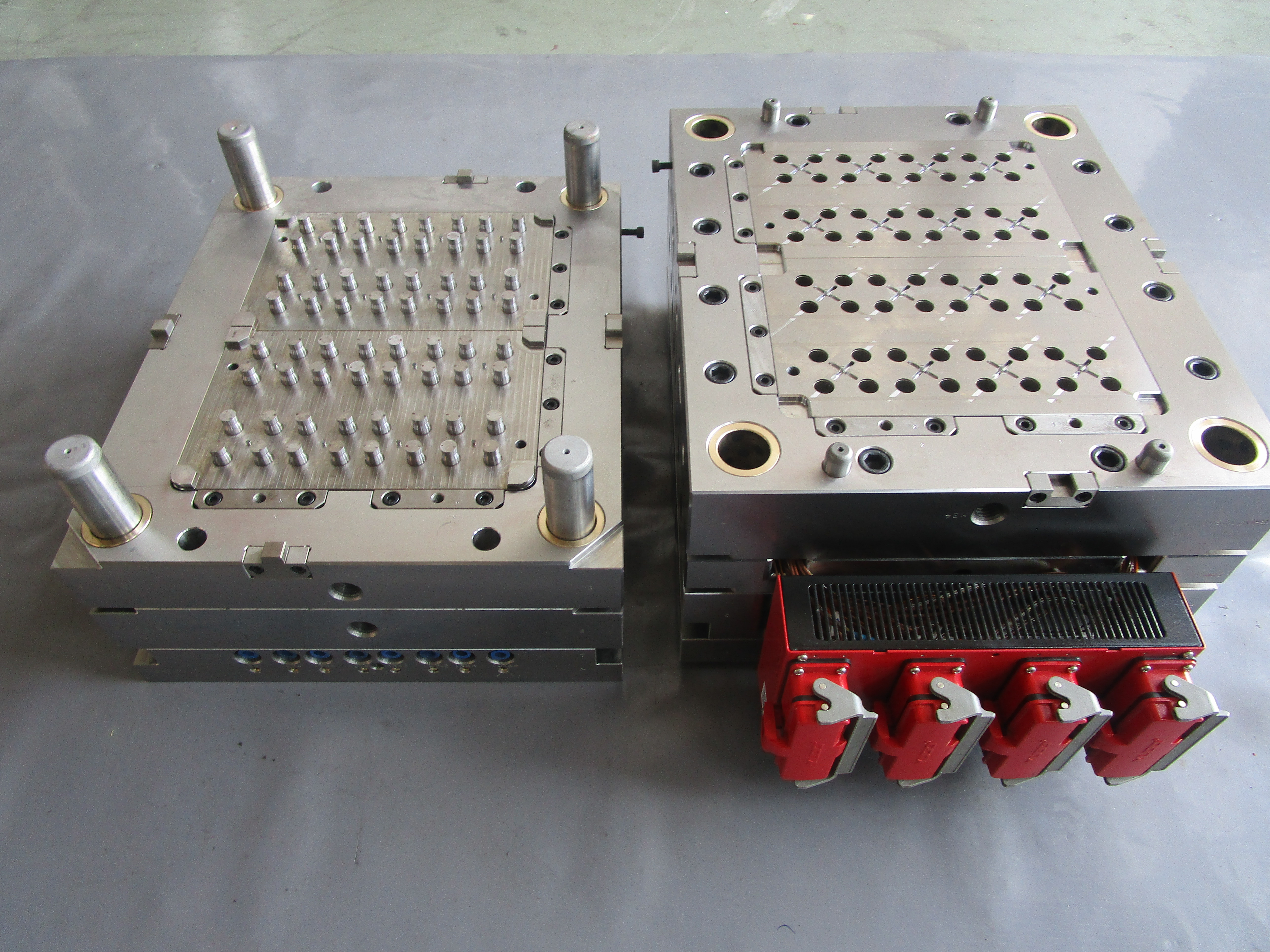

Bộ mặt ngành sản xuất đã thay đổi mạnh mẽ trong những năm gần đây, với các dịch vụ ép phun theo yêu cầu ép nhựa dịch vụ nổi lên như một trụ cột trong các phương pháp sản xuất hiện đại. Quy trình sản xuất tinh vi này cho phép doanh nghiệp tạo ra các bộ phận nhựa phức tạp với độ chính xác và hiệu quả chưa từng có. Khi các ngành công nghiệp từ ô tô đến thiết bị y tế đang tìm kiếm những giải pháp đổi mới cho nhu cầu sản xuất của mình, các dịch vụ ép phun tùy chỉnh đã trở nên ngày càng quan trọng đối với các công ty nhằm duy trì lợi thế cạnh tranh đồng thời đảm bảo chất lượng và độ nhất quán của sản phẩm.

Tính linh hoạt và độ tin cậy của các dịch vụ ép phun tùy chỉnh đã làm thay đổi cách mà doanh nghiệp tiếp cận phát triển sản phẩm và sản xuất. Công nghệ tiên tiến này cho phép sản xuất mọi thứ từ các thiết bị y tế phức tạp đến các bộ phận ô tô bền bỉ, trong khi vẫn duy trì các tiêu chuẩn chất lượng nghiêm ngặt và hiệu quả về chi phí. Khi đi sâu hơn vào những lợi thế của phương pháp sản xuất này, rõ ràng vì sao ngày càng nhiều công ty đang chuyển sang sử dụng ép phun tùy chỉnh cho nhu cầu sản xuất của họ.

Xuất Sắc Trong Sản Xuất và Lợi Ích Sản Xuất

Độ chính xác và Kiểm soát chất lượng

Dịch vụ đúc phun tùy chỉnh cung cấp độ chính xác vượt trội trong sản xuất các bộ phận nhựa. Quy trình này sử dụng các hệ thống điều khiển bằng máy tính tiên tiến, đảm bảo mỗi bộ phận đáp ứng đúng thông số kỹ thuật, duy trì sự nhất quán trong suốt quá trình sản xuất. Mức độ chính xác này đặc biệt quan trọng đối với các ngành công nghiệp mà độ chính xác của bộ phận có thể quyết định giữa thành công và thất bại.

Các biện pháp kiểm soát chất lượng trong đúc phun tùy chỉnh rất toàn diện và tinh vi. Từ khâu chọn vật liệu đến kiểm tra cuối cùng, từng bước trong quy trình đều được giám sát và kiểm soát để duy trì tiêu chuẩn cao nhất. Các cơ sở đúc phun hiện đại sử dụng các công nghệ đảm bảo chất lượng tiên tiến, bao gồm các hệ thống thiết kế hỗ trợ bằng máy tính (CAD) và thiết bị kiểm tra tự động, đảm bảo rằng mỗi sản phẩm đều đạt hoặc vượt các tiêu chuẩn ngành.

Hiệu quả sản xuất và khả năng mở rộng

Một trong những lợi thế đáng kể nhất của dịch vụ đúc phun tùy chỉnh là hiệu quả sản xuất vượt trội mà chúng mang lại. Sau khi khuôn đã được tạo ra và quy trình được tối ưu hóa, các nhà sản xuất có thể nhanh chóng sản xuất hàng nghìn bộ phận giống hệt nhau một cách nhất quán. Khả năng sản xuất số lượng lớn này khiến phương pháp đúc phun trở nên đặc biệt tiết kiệm chi phí cho các đợt sản xuất quy mô lớn.

Tính linh hoạt về quy mô của quy trình đúc phun cho phép doanh nghiệp điều chỉnh khối lượng sản xuất theo nhu cầu. Dù công ty cần một lô nhỏ các bộ phận chuyên dụng hay hàng triệu bộ phận để sản xuất hàng loạt, dịch vụ đúc phun tùy chỉnh đều có thể đáp ứng các yêu cầu sản xuất khác nhau trong khi vẫn duy trì chất lượng và hiệu quả chi phí ổn định.

Tối ưu hóa chi phí và nguồn lực

Giảm thiểu nguyên vật liệu và chất thải

Dịch vụ đúc phun tùy chỉnh nổi bật trong hiệu quả sử dụng vật liệu, giảm đáng kể lượng chất thải so với các phương pháp sản xuất truyền thống. Quy trình này cho phép tính toán chính xác nhu cầu vật liệu, và bất kỳ vật liệu dư thừa nào thường có thể được tái chế và sử dụng lại trong các lần sản xuất tiếp theo. Hiệu quả này không chỉ giúp giảm chi phí mà còn phù hợp với các thực hành sản xuất bền vững.

Khả năng lựa chọn từ một loạt các loại vật liệu cho phép các nhà sản xuất tối ưu hóa cả chi phí và hiệu suất. Từ các loại nhựa nhiệt dẻo tiêu chuẩn đến các polymer kỹ thuật hiệu suất cao, dịch vụ đúc phun tùy chỉnh có thể làm việc với những vật liệu phù hợp nhất với yêu cầu ứng dụng cụ thể, đồng thời cân nhắc đến các ràng buộc về ngân sách.

Lợi ích chi phí dài hạn

Mặc dù chi phí ban đầu cho các dịch vụ đúc khuôn tùy chỉnh có vẻ khá lớn, nhưng lợi ích tài chính về lâu dài là đáng kể. Quy trình với hiệu suất cao và tự động hóa giúp giảm chi phí nhân công, trong khi độ bền của các khuôn hiện đại đảm bảo tuổi thọ sản xuất dài hạn với yêu cầu bảo trì tối thiểu.

Hơn nữa, sự nhất quán và chất lượng của các bộ phận đúc khuôn thường dẫn đến tỷ lệ loại bỏ thấp hơn và ít vấn đề liên quan đến chất lượng hơn, từ đó giảm tổng chi phí sản xuất. Khả năng sản xuất các bộ phận phức tạp trong một lần vận hành cũng loại bỏ nhu cầu các quy trình lắp ráp thứ cấp, mang lại thêm tiết kiệm chi phí.

Độ linh hoạt trong thiết kế và đổi mới

Khả năng Hình học Phức tạp

Các dịch vụ đúc khuôn tùy chỉnh cho phép sản xuất các bộ phận có thiết kế tinh vi và hình học phức tạp mà sẽ rất khó hoặc không thể đạt được bằng các phương pháp sản xuất khác. Khả năng này cho phép các nhà thiết kế tạo ra các giải pháp đổi mới mà không bị giới hạn bởi những hạn chế truyền thống của sản xuất.

Quy trình này có thể đáp ứng nhiều tính năng thiết kế khác nhau như khớp nối kiểu bấm, bản lề dẻo và ren trong, đồng thời vẫn duy trì độ chính xác cao và độ bền cấu trúc. Sự linh hoạt trong khả năng thiết kế này mở ra những khả năng mới cho đổi mới và cải tiến sản phẩm.

Tạo mẫu nhanh và lặp lại thiết kế

Các dịch vụ đúc phun tùy chỉnh hiện đại thường tích hợp khả năng tạo mẫu nhanh, cho phép thực hiện nhanh các lần lặp thiết kế và kiểm tra nguyên mẫu. Quy trình phát triển được tăng tốc này giúp các công ty đưa sản phẩm ra thị trường nhanh hơn, đồng thời đảm bảo tối ưu hóa thiết kế và chức năng.

Khả năng sản xuất nhanh các bộ phận mẫu giúp phát hiện và giải quyết sớm các vấn đề tiềm ẩn trong quá trình phát triển, giảm nguy cơ phải thay đổi tốn kém trong giai đoạn sản xuất hàng loạt. Cách tiếp cận lặp lại này trong thiết kế và sản xuất dẫn đến sản phẩm tốt hơn và quy trình sản xuất hiệu quả hơn.

Các câu hỏi thường gặp

Những ngành nào được hưởng lợi nhiều nhất từ các dịch vụ đúc phun tùy chỉnh?

Dịch vụ đúc phun tùy chỉnh có lợi cho nhiều ngành công nghiệp, bao gồm ô tô, thiết bị y tế, điện tử tiêu dùng, hàng không vũ trụ và thiết bị gia dụng. Bất kỳ ngành công nghiệp nào đòi hỏi các thành phần nhựa chất lượng cao và chính xác được sản xuất trên quy mô lớn đều có thể được hưởng lợi từ phương pháp sản xuất này.

Phải mất bao lâu để thiết lập một dự án đúc phun tùy chỉnh?

Thời gian thiết lập cho một dự án đúc phun tùy chỉnh thường dao động từ 4-12 tuần, tùy thuộc vào độ phức tạp của bộ phận, yêu cầu thiết kế khuôn và lựa chọn vật liệu. Điều này bao gồm các giai đoạn xem xét thiết kế, tạo khuôn, thử nghiệm và tối ưu hóa.

Các loại vật liệu nào có thể được sử dụng trong đúc phun tùy chỉnh?

Dịch vụ đúc phun tùy chỉnh có thể làm việc với nhiều loại vật liệu nhiệt dẻo, bao gồm ABS, polypropylene, polyethylene, polycarbonate, nylon và các loại polymer cấp kỹ thuật khác. Việc lựa chọn vật liệu phụ thuộc vào các yêu cầu cụ thể của ứng dụng, chẳng hạn như độ bền, độ linh hoạt, khả năng chịu nhiệt và tính tương thích hóa học.