Hiểu rõ thế giới phức tạp của các công nghệ sản xuất tiên tiến

Lĩnh vực chính xác OEM tooling đại diện cho một trong những lĩnh vực sản xuất đòi hỏi khắt khe nhất, nơi dung sai được đo bằng micron và các tiêu chuẩn chất lượng là tuyệt đối. Khi các ngành công nghiệp phát triển và thông số kỹ thuật sản phẩm ngày càng phức tạp, các nhà sản xuất phải đối mặt với áp lực ngày càng lớn trong việc cung cấp các dụng cụ và linh kiện đáp ứng yêu cầu chính xác đồng thời duy trì hiệu quả về chi phí và thời gian hoàn thành nhanh chóng.

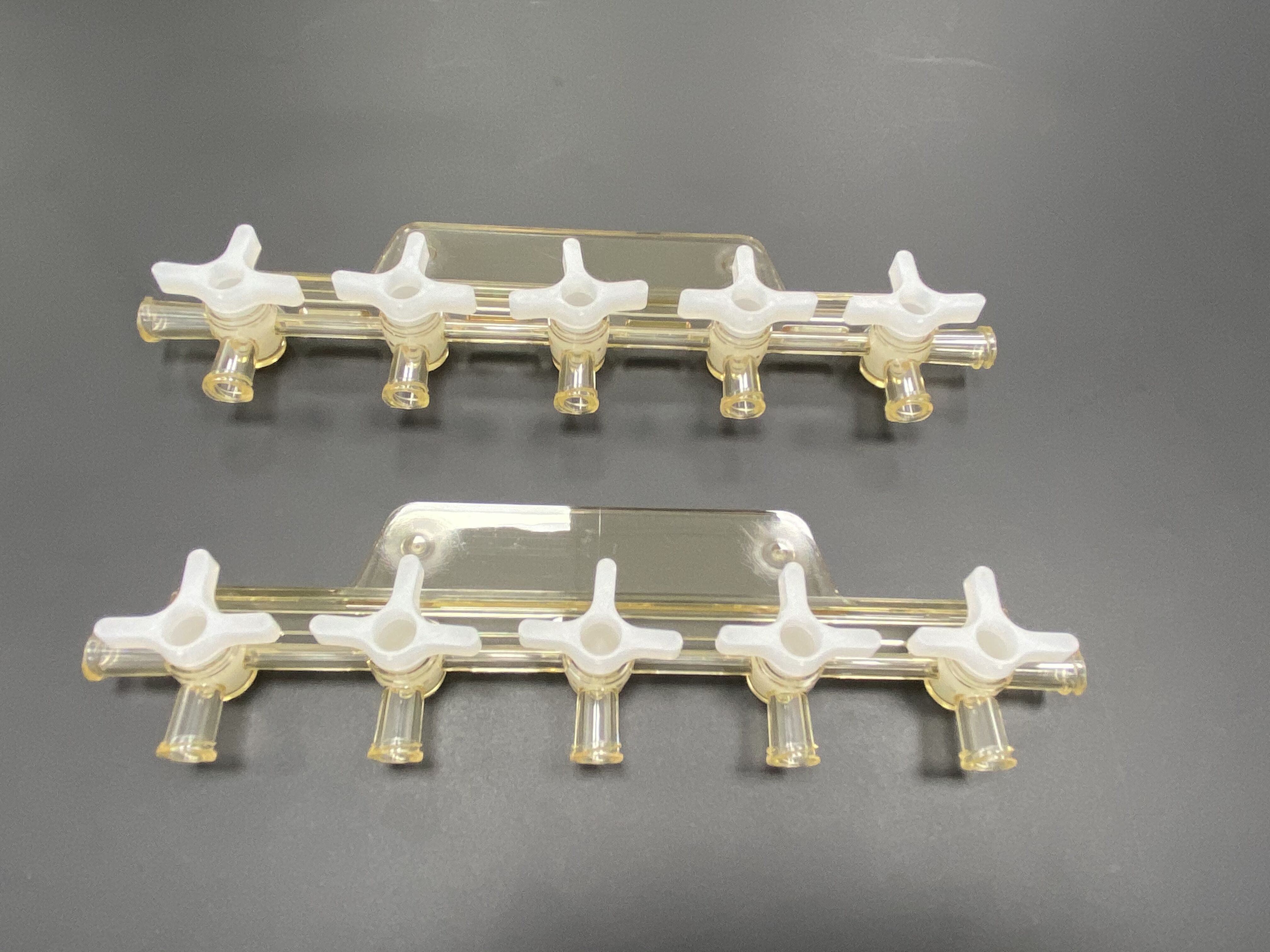

Các dụng cụ OEM chính xác hiện đại bao gồm nhiều quy trình sản xuất khác nhau, từ gia công CNC và các thao tác EDM đến các công nghệ phủ tiên tiến và hệ thống kiểm soát chất lượng. Mỗi khía cạnh đều đặt ra những thách thức kỹ thuật riêng mà các nhà sản xuất phải vượt qua để duy trì tính cạnh tranh trên thị trường toàn cầu ngày nay.

Các thách thức sản xuất liên quan đến vật liệu

Lựa Chọn Và Xử Lý Vật Liệu Tiên Tiến

Một trong những thách thức cơ bản trong gia công dụng cụ OEM chính xác là lựa chọn và xử lý các vật liệu phù hợp. Các kỹ sư phải cân nhắc các yếu tố như độ cứng, khả năng chống mài mòn, ổn định nhiệt và khả năng gia công khi chọn vật liệu cho các ứng dụng cụ thể. Những vật liệu hiệu suất cao như cacbua, gốm và các hợp kim tiên tiến thường yêu cầu các kỹ thuật xử lý và gia công đặc biệt.

Độ phức tạp tăng lên khi làm việc với các vật liệu mới được thiết kế cho các ngành công nghiệp cụ thể. Ví dụ, các bộ phận hàng không vũ trụ có thể yêu cầu các hợp kim đặc biệt có đặc tính gia công độc đáo, trong khi dụng cụ chế tạo thiết bị y tế có thể đòi hỏi các vật liệu tương thích sinh học với yêu cầu hoàn thiện bề mặt chính xác.

Quản lý Nhiệt và Độ Ổn Định Kích Thước

Kiểm soát nhiệt độ trong các quy trình sản xuất đặt ra một thách thức quan trọng khác. Hành vi của vật liệu trong các điều kiện nhiệt khác nhau có thể ảnh hưởng đến độ chính xác về kích thước và chất lượng bề mặt. Các nhà sản xuất dụng cụ OEM chính xác phải triển khai các hệ thống làm mát tinh vi và các giao thức giám sát nhiệt độ để duy trì sự ổn định trong suốt quá trình sản xuất.

Thách thức này mở rộng sang các công đoạn gia công sau, nơi mà xử lý nhiệt và hoàn thiện bề mặt phải được kiểm soát cẩn thận để tránh biến dạng đồng thời đạt được các tính chất vật liệu mong muốn. Điều này đòi hỏi chuyên môn sâu rộng trong lĩnh vực luyện kim và các kỹ thuật xử lý nhiệt.

Hệ thống Kiểm soát và Đo lường Chính xác

Yêu cầu Đo lường Tiên tiến

Nhu cầu ngày càng tăng đối với các dung sai chặt chẽ hơn trong dụng cụ OEM chính xác đòi hỏi các hệ thống đo lường và kiểm tra tinh vi. Các nhà sản xuất phải đầu tư vào thiết bị đo lường tiên tiến và phát triển các quy trình kiểm soát chất lượng nghiêm ngặt để xác minh độ chính xác về kích thước, độ hoàn thiện bề mặt và các dung sai hình học.

Việc phối hợp các hệ thống đo lường qua các giai đoạn sản xuất khác nhau trong khi duy trì độ hiệu chuẩn và tính nhất quán của phép đo đặt ra những thách thức liên tục. Việc tích hợp các hệ thống đo lường trong quá trình với thiết bị sản xuất làm tăng thêm mức độ phức tạp cho các hoạt động kiểm soát chất lượng.

Điều khiển Máy móc và Tối ưu hóa Quy trình

Đạt được và duy trì việc kiểm soát chính xác các quy trình sản xuất đòi hỏi các hệ thống CNC tiên tiến và khả năng lập trình tinh vi. Các nhà sản xuất phải tối ưu hóa các thông số cắt, đường dao và trình tự quy trình trong khi cân nhắc nhiều biến ảnh hưởng đến chất lượng sản phẩm cuối cùng.

Thách thức về tối ưu hóa quy trình còn mở rộng sang việc quản lý mài mòn dụng cụ, bù trừ động lực học máy và duy trì hiệu suất ổn định qua nhiều đợt sản xuất. Điều này đòi hỏi việc giám sát và điều chỉnh liên tục các thông số quy trình dựa trên phân tích dữ liệu thời gian thực.

Tích hợp Số hóa và Việc Áp dụng Công nghiệp 4.0

Quản lý Dữ liệu và Giám sát Quy trình

Việc triển khai các hệ thống sản xuất kỹ thuật số mang lại cả cơ hội và thách thức cho các nhà sản xuất dụng cụ OEM chính xác. Việc thu thập, phân tích và sử dụng hiệu quả dữ liệu sản xuất đòi hỏi cơ sở hạ tầng CNTT vững chắc và chuyên môn chuyên sâu trong các hệ thống quản lý dữ liệu.

Các hệ thống giám sát theo thời gian thực và điều khiển thích ứng phải được tích hợp với các quy trình sản xuất hiện có trong khi vẫn duy trì hiệu suất sản xuất. Điều này bao gồm việc triển khai cảm biến, phát triển các thuật toán phân tích dữ liệu và tạo ra các vòng phản hồi ý nghĩa nhằm cải thiện quy trình.

Tự động hóa và Tích hợp Hệ thống

Tự động hóa các quy trình sản xuất chính xác trong khi vẫn đảm bảo chất lượng và tính linh hoạt đặt ra những thách thức kỹ thuật đáng kể. Các nhà sản xuất phải cân bằng giữa lợi ích của tự động hóa và nhu cầu về chuyên môn con người trong các tình huống ra quyết định phức tạp và giải quyết vấn đề.

Việc tích hợp các hệ thống sản xuất khác nhau, từ phần mềm CAD/CAM đến thiết bị sản xuất và các hệ thống kiểm soát chất lượng, đòi hỏi phải lập kế hoạch và triển khai cẩn thận để đảm bảo hoạt động liền mạch và luồng dữ liệu thông suốt trong suốt quá trình sản xuất.

Thách thức trong Chuỗi cung ứng và Lập kế hoạch sản xuất

Nguồn cung vật liệu và linh kiện

Đảm bảo nguồn cung ổn định các vật liệu và linh kiện chất lượng cao cho sản xuất dụng cụ chính xác OEM có thể rất khó khăn. Các nhà sản xuất phải duy trì mối quan hệ với các nhà cung cấp đáng tin cậy đồng thời quản lý hiệu quả mức tồn kho và thời gian chờ hàng.

Tính chất toàn cầu của chuỗi cung ứng hiện đại làm tăng thêm độ phức tạp trong các quyết định tìm nguồn cung, với các yếu tố cần cân nhắc như sự nhất quán về chất lượng, hậu cần vận chuyển và tuân thủ quy định tại các khu vực khác nhau.

Lập lịch sản xuất và Phân bổ nguồn lực

Tối ưu hóa lịch sản xuất trong khi vẫn duy trì tính linh hoạt cho các đơn hàng khẩn cấp đòi hỏi các hệ thống lập kế hoạch tinh vi và phân bổ tài nguyên cẩn thận. Các nhà sản xuất phải cân bằng giữa việc sử dụng máy móc, lên lịch lao động và yêu cầu bảo trì, đồng thời đáp ứng kỳ vọng giao hàng của khách hàng.

Quản lý nhiều dự án song song với các mức độ phức tạp và mức độ ưu tiên khác nhau đặt ra những thách thức liên tục trong lập kế hoạch sản xuất và phân bổ nguồn lực.

Các câu hỏi thường gặp

Các yếu tố môi trường ảnh hưởng như thế nào đến sản xuất dụng cụ OEM chính xác?

Các yếu tố môi trường như nhiệt độ, độ ẩm và rung động có thể ảnh hưởng đáng kể đến độ chính xác trong sản xuất. Các nhà sản xuất phải duy trì môi trường được kiểm soát với điều kiện ổn định để đảm bảo chất lượng nhất quán. Điều này thường đòi hỏi đầu tư vào các hệ thống điều hòa khí hậu, cách ly rung động và giám sát môi trường định kỳ.

Hoàn thiện bề mặt đóng vai trò gì trong chất lượng dụng cụ chính xác?

Hoàn thiện bề mặt rất quan trọng trong gia công dụng cụ OEM chính xác vì nó ảnh hưởng đến cả chức năng và độ bền. Xử lý bề mặt đúng cách có thể tăng cường khả năng chống mài mòn, giảm ma sát và cải thiện khả năng bảo vệ chống ăn mòn. Đạt được chất lượng bề mặt đồng đều đòi hỏi thiết bị chuyên dụng và chuyên môn về các kỹ thuật hoàn thiện khác nhau.

Các công nghệ mới nổi đang thay đổi sản xuất chính xác như thế nào?

Các công nghệ mới nổi như trí tuệ nhân tạo, học máy và sản xuất cộng thêm đang làm thay đổi lĩnh vực gia công dụng cụ OEM chính xác. Những công nghệ này cho phép tối ưu hóa quy trình hiệu quả hơn, bảo trì dự đoán và sản xuất các hình dạng phức tạp mà trước đây rất khó hoặc không thể chế tạo bằng các phương pháp truyền thống.