Hiểu rõ những điểm khác biệt cốt lõi của dụng cụ sản xuất thiết bị gốc

Ngành công nghiệp sản xuất phụ thuộc rất nhiều vào các công cụ và thiết bị chính xác để tạo ra các sản phẩm chất lượng cao. Khi nói đến các giải pháp dụng cụ, thường có sự nhầm lẫn giữa dụng cụ OEM và các lựa chọn dụng cụ thông thường. Hai danh mục này phục vụ các mục đích khác nhau và đi kèm với những đặc điểm riêng biệt, có thể ảnh hưởng đáng kể đến kết quả sản xuất, hiệu quả chi phí và chất lượng sản xuất tổng thể.

Sự khác biệt giữa OEM tooling và dụng cụ thông thường không chỉ đơn thuần là sự khác biệt về thương hiệu hoặc giá cả. Nó bao gồm các khía cạnh như thông số thiết kế, tiêu chuẩn chất lượng, phạm vi bảo hành và độ tin cậy lâu dài mà các nhà sản xuất phải cân nhắc kỹ lưỡng khi đưa ra quyết định về dụng cụ. Việc hiểu rõ những khác biệt này là rất quan trọng để đưa ra các lựa chọn sáng suốt, phù hợp với yêu cầu sản xuất và mục tiêu kinh doanh.

Đặc điểm cốt lõi của dụng cụ OEM

Độ chính xác và thông số thiết kế

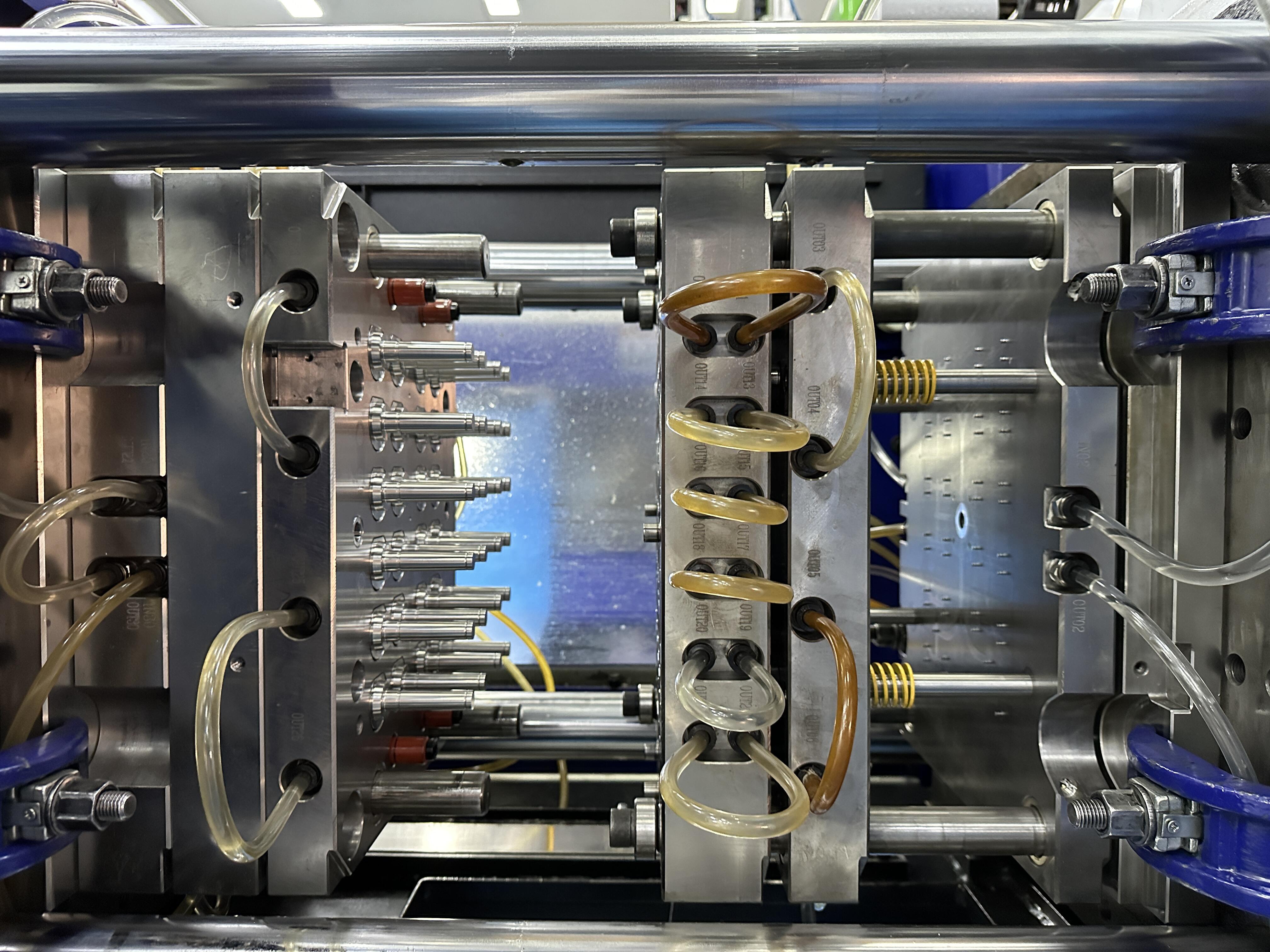

Dụng cụ OEM được thiết kế đặc biệt để đáp ứng chính xác các thông số kỹ thuật và tiêu chuẩn của nhà sản xuất. Những dụng cụ này được thiết kế với các kích thước và dung sai chính xác, phù hợp hoàn hảo với yêu cầu của thiết bị gốc. Quá trình kỹ thuật bao gồm phân tích chi tiết các tính chất vật liệu, các yếu tố ứng suất và điều kiện vận hành để đảm bảo hiệu suất tối ưu.

Việc phát triển dụng cụ OEM thường tích hợp các hệ thống thiết kế hỗ trợ bằng máy tính tiên tiến (CAD) và các quy trình kiểm tra nghiêm ngặt. Sự chú trọng đến từng chi tiết này đảm bảo rằng mỗi dụng cụ tích hợp hoàn hảo với máy móc dự định và tạo ra kết quả đồng nhất, chất lượng cao trong suốt vòng đời hoạt động của nó.

Kiểm soát chất lượng và chứng nhận

Một trong những khía cạnh quan trọng nhất của dụng cụ OEM là các biện pháp kiểm soát chất lượng nghiêm ngặt được thực hiện trong quá trình sản xuất. Mỗi dụng cụ đều trải qua các quy trình kiểm tra và xác minh kỹ lưỡng để đảm bảo đáp ứng các thông số kỹ thuật của nhà sản xuất thiết bị gốc. Điều này bao gồm phân tích thành phần vật liệu, kiểm tra độ chính xác về kích thước và thử nghiệm hiệu suất trong các điều kiện khác nhau.

Quy trình chứng nhận đối với dụng cụ OEM thường toàn diện hơn so với dụng cụ thông thường. Các chứng nhận này thường bao gồm tài liệu chi tiết về kết quả thử nghiệm, chứng nhận vật liệu và sự tuân thủ các tiêu chuẩn sản xuất quốc tế. Mức độ đảm bảo chất lượng này mang lại cho các nhà sản xuất sự tin tưởng vào độ tin cậy và hiệu suất của dụng cụ.

Đặc điểm và Ứng dụng của Dụng cụ Thông thường

Tiêu chuẩn Sản xuất và Tính Đa dụng

Dụng cụ thông thường, mặc dù vẫn được sản xuất để đáp ứng các tiêu chuẩn công nghiệp, thường tuân theo các thông số kỹ thuật chung hơn. Những dụng cụ này được thiết kế để linh hoạt và tương thích với nhiều loại thiết bị khác nhau thay vì được tối ưu hóa cho máy móc cụ thể. Cách tiếp cận này cho phép ứng dụng rộng rãi hơn nhưng có thể dẫn đến sự khác biệt nhỏ về hiệu suất hoặc độ vừa khít.

Quy trình sản xuất dụng cụ thông thường thường tập trung vào việc đáp ứng các yêu cầu chung của ngành trong khi vẫn đảm bảo tính hiệu quả về chi phí. Mặc dù các biện pháp kiểm soát chất lượng vẫn được thực hiện, nhưng chúng có thể không nghiêm ngặt như những yêu cầu áp dụng cho dụng cụ OEM.

Xem xét chi phí và tính sẵn có

Dụng cụ thông thường thường có chi phí ban đầu thấp hơn so với các lựa chọn OEM. Sự chênh lệch về giá này phản ánh quy trình sản xuất tiêu chuẩn hóa hơn và khả năng sẵn có trên thị trường rộng lớn hơn. Nhiều nhà sản xuất chọn dụng cụ thông thường cho các ứng dụng không quan trọng hoặc khi các ràng buộc về ngân sách là yếu tố chính được cân nhắc.

Việc sẵn có rộng rãi các dụng cụ thông thường đồng nghĩa với thời gian mua hàng nhanh hơn và nhiều lựa chọn nhà cung cấp hơn. Điều này đặc biệt có lợi khi cần thay thế nhanh chóng hoặc khi thiết lập mối quan hệ với nhiều nhà cung cấp nhằm đảm bảo an toàn chuỗi cung ứng.

So sánh hiệu suất và độ bền

Hiệu quả hoạt động

Dụng cụ OEM thường thể hiện hiệu quả vận hành vượt trội nhờ các thông số thiết kế chính xác. Những dụng cụ này thường yêu cầu ít thời gian điều chỉnh hơn trong quá trình lắp đặt và duy trì mức độ hiệu suất ổn định trong suốt vòng đời hoạt động. Việc khớp chính xác với thông số kỹ thuật của thiết bị có thể giúp giảm mài mòn cả dụng cụ lẫn máy móc mà nó được sử dụng cùng.

Dụng cụ thông thường có thể đòi hỏi điều chỉnh và giám sát thường xuyên hơn để duy trì hiệu suất tối ưu. Mặc dù có khả năng đáp ứng các yêu cầu sản xuất, những dụng cụ này có thể không đạt được mức hiệu quả như các loại dụng cụ OEM tương ứng, đặc biệt trong các ứng dụng đòi hỏi độ chính xác cao.

Thời gian sử dụng và yêu cầu bảo dưỡng

Tuổi thọ của dụng cụ OEM thường vượt trội so với dụng cụ thông thường, đặc biệt trong các ứng dụng yêu cầu cao. Độ bền kéo dài này đạt được nhờ vật liệu tốt hơn, kỹ thuật chính xác và thiết kế tối ưu cho từng trường hợp sử dụng cụ thể. Mặc dù chi phí đầu tư ban đầu cao hơn, tổng chi phí sở hữu có thể thấp hơn do tần suất thay thế giảm.

Yêu cầu bảo trì có thể khác biệt đáng kể giữa dụng cụ OEM và dụng cụ thông thường. Dụng cụ OEM thường đi kèm hướng dẫn bảo trì chi tiết và có thể yêu cầu các quy trình hoặc vật liệu cụ thể để duy trì hiệu lực bảo hành. Dụng cụ thông thường thường tuân theo các quy trình bảo trì tiêu chuẩn nhưng có thể cần được chăm sóc thường xuyên hơn để duy trì hiệu suất tối ưu.

Lựa chọn phù hợp cho nhu cầu sản xuất của bạn

Đánh giá ứng dụng

Việc lựa chọn giữa dụng cụ OEM và dụng cụ thông thường đòi hỏi phải đánh giá cẩn thận các yêu cầu sản xuất cụ thể của bạn. Các yếu tố quan trọng bao gồm khối lượng sản xuất, yêu cầu độ chính xác, giới hạn ngân sách và mục tiêu hoạt động dài hạn. Các quy trình sản xuất đòi hỏi độ chính xác cao hoặc các công đoạn sản xuất then chốt thường hợp lý hóa việc đầu tư vào dụng cụ OEM.

Hãy cân nhắc tác động của lựa chọn dụng cụ đến chất lượng sản phẩm, hiệu quả sản xuất và hiệu suất tổng thể của thiết bị. Một số ứng dụng có thể hưởng lợi từ cách tiếp cận kết hợp, sử dụng dụng cụ OEM cho các công đoạn then chốt và dụng cụ thông thường cho các nhiệm vụ ít yêu cầu hơn.

Phân tích tổng chi phí

Phân tích chi phí toàn diện nên xem xét nhiều yếu tố hơn là chỉ giá mua ban đầu. Cần tính đến tuổi thọ dự kiến của dụng cụ, yêu cầu bảo trì, chi phí ngừng hoạt động tiềm năng và ảnh hưởng đến chất lượng sản phẩm. Chi phí ban đầu cao hơn của dụng cụ OEM có thể được bù đắp bởi hiệu suất cải thiện, tuổi thọ sử dụng lâu dài hơn và nhu cầu bảo trì giảm.

Cũng cần xem xét tác động tiềm tàng đến phạm vi bảo hành của thiết bị chính. Một số nhà sản xuất có thể yêu cầu sử dụng dụng cụ OEM để duy trì bảo hành thiết bị, do đó việc lựa chọn này rất quan trọng nhằm bảo vệ khoản đầu tư vốn của bạn.

Các câu hỏi thường gặp

Phạm vi bảo hành khác nhau như thế nào giữa dụng cụ OEM và dụng cụ thông thường?

Dụng cụ OEM thường đi kèm với phạm vi bảo hành toàn diện hơn, thường bao gồm các cam kết hiệu suất cụ thể và thời gian bảo hành dài hơn. Các bảo hành dụng cụ thông thường thường giới hạn hơn về phạm vi và thời gian, chủ yếu tập trung vào các lỗi vật liệu và sản xuất.

Dụng cụ thông thường có thể mang lại kết quả chất lượng tương đương với dụng cụ OEM không?

Mặc dù dụng cụ thông thường có thể tạo ra kết quả chấp nhận được trong nhiều ứng dụng, dụng cụ OEM nói chung cung cấp độ chính xác và tính nhất quán vượt trội hơn, đặc biệt trong các quy trình sản xuất đòi hỏi độ chính xác cao. Sự khác biệt này trở nên rõ rệt hơn trong các ứng dụng khắt khe nơi dung sai chặt chẽ là yếu tố then chốt.

Những yếu tố nào nên ảnh hưởng đến việc lựa chọn giữa dụng cụ OEM và dụng cụ thông thường?

Các yếu tố cần cân nhắc chính bao gồm yêu cầu ứng dụng, nhu cầu độ chính xác, giới hạn ngân sách, khối lượng sản xuất, yêu cầu bảo hành thiết bị và các tác động về chi phí dài hạn. Quyết định nên cân bằng giữa các lo ngại về chi phí trước mắt với hiệu quả hoạt động và yêu cầu chất lượng lâu dài.