Làm Chủ Nghệ Thuật Sản Xuất Chính Xác Thông Qua Ép Phun Khuôn

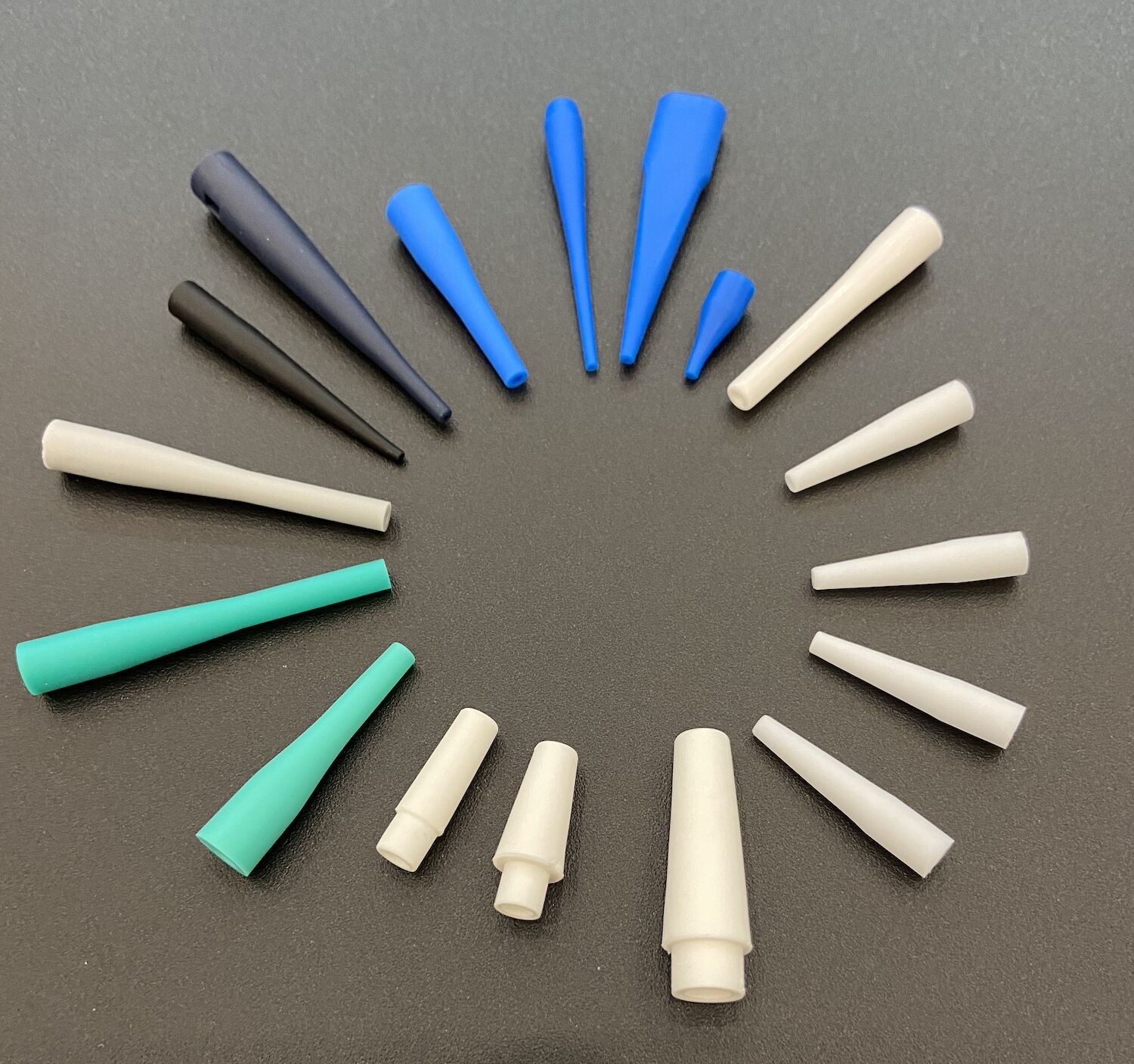

Bối cảnh sản xuất liên tục phát triển, và ép phun tùy chỉnh ép nhựa đang dẫn đầu các kỹ thuật sản xuất hiện đại. Quy trình tinh vi này đã cách mạng hóa cách chúng ta tạo ra các bộ phận nhựa, mang lại độ chính xác, tính nhất quán và khả năng mở rộng chưa từng có. Khi các ngành công nghiệp từ ô tô đến thiết bị y tế đều áp dụng công nghệ này, việc hiểu rõ các chi tiết của nó trở nên cực kỳ quan trọng đối với các nhà sản xuất nhằm đạt được chất lượng vượt trội trong sản phẩm của họ.

Gia công khuôn ép phun tùy chỉnh đã phát triển từ một phương pháp sản xuất đơn giản thành một quy trình chuyên biệt cao, kết hợp giữa chuyên môn kỹ thuật, khoa học vật liệu tiên tiến và công nghệ hiện đại. Các nhà sản xuất ngày nay tận dụng kỹ thuật linh hoạt này để sản xuất mọi thứ, từ các thiết bị y tế phức tạp đến các bộ phận ô tô bền bỉ, đồng thời vẫn đảm bảo tiêu chuẩn chất lượng cao và hiệu quả về chi phí.

Các Thành Phần Thiết Yếu Của Thành Công Trong Gia Công Khuôn Ép Phun Tùy Chỉnh

Lựa chọn và Tối ưu Hóa Vật liệu

Nền tảng của sự thành công trong gia công khuôn ép phun tùy chỉnh bắt đầu từ việc lựa chọn đúng vật liệu. Các loại polymer khác nhau thể hiện những đặc tính khác nhau, từ khả năng chịu nhiệt đến độ linh hoạt, và việc lựa chọn vật liệu tối ưu sẽ ảnh hưởng trực tiếp đến chất lượng sản phẩm. Các kỹ sư phải cân nhắc các yếu tố như tính chất cơ học, khả năng chống hóa chất và điều kiện môi trường khi đưa ra quyết định về vật liệu.

Các loại nhựa nhiệt dẻo tiên tiến như polyethylene, polypropylene và các loại nhựa kỹ thuật cung cấp nhiều lựa chọn đa dạng cho các ứng dụng khác nhau. Mỗi loại vật liệu yêu cầu các thông số gia công cụ thể, và việc hiểu rõ những yêu cầu này đảm bảo chất lượng sản phẩm ổn định. Việc lựa chọn vật liệu cũng ảnh hưởng đến thời gian chu kỳ, mài mòn khuôn và hiệu suất sản xuất tổng thể.

Thiết kế và Kỹ thuật Khuôn

Khuôn là trung tâm của các hoạt động đúc phun tùy chỉnh. Thiết kế khuôn phù hợp cần tính đến hình học chi tiết, dòng chảy vật liệu, hiệu quả làm mát và cơ chế đẩy sản phẩm ra. Các kỹ sư phải xem xét các yếu tố như sự thay đổi độ dày thành, góc thoát và vị trí cổng phun để ngăn ngừa các khuyết tật phổ biến như cong vênh hay vết lõm.

Thiết kế khuôn hiện đại tận dụng phần mềm mô phỏng tiên tiến để tối ưu hóa các mẫu dòng chảy và dự đoán các vấn đề tiềm ẩn trước khi sản xuất bắt đầu. Cách tiếp cận chủ động này giúp tiết kiệm thời gian và nguồn lực đồng thời đảm bảo đầu ra chất lượng cao hơn. Việc tích hợp các kênh làm mát định hình và bố trí cổng phun chiến lược còn nâng cao chất lượng sản phẩm và giảm thời gian chu kỳ.

Kiểm soát Quy trình Nâng cao và Tối ưu hóa

Hệ thống Quản lý Nhiệt độ

Duy trì kiểm soát nhiệt độ chính xác trong suốt quá trình ép phun tùy chỉnh là yếu tố then chốt đối với chất lượng sản phẩm. Điều này bao gồm việc quản lý cả nhiệt độ nóng chảy và nhiệt độ khuôn bằng các hệ thống điều khiển tinh vi. Thiết bị hiện đại được trang bị nhiều vùng nhiệt độ và cảm biến tiên tiến để đảm bảo quá trình gia nhiệt và làm mát đồng đều.

Quản lý nhiệt độ đúng cách ngăn ngừa các khuyết tật phổ biến như hiện tượng điền đầy không đủ, vết cháy và suy giảm vật liệu. Nó cũng tối ưu hóa thời gian chu kỳ và đảm bảo chất lượng sản phẩm ổn định trong suốt các đợt sản xuất. Việc áp dụng các hệ thống giám sát nhiệt độ thông minh cho phép điều chỉnh theo thời gian thực và kiểm soát chất lượng.

Điều khiển Áp suất và Lưu lượng

Kiểm soát áp suất chính xác trong các giai đoạn tiêm và nén chặt ảnh hưởng đáng kể đến chất lượng sản phẩm. Các máy ép phun tùy chỉnh hiện đại sử dụng cảm biến áp suất tiên tiến và các hệ thống điều khiển để duy trì hồ sơ áp suất chính xác trong suốt chu kỳ. Điều này đảm bảo dòng chảy và nén vật liệu phù hợp, ngăn ngừa các khuyết tật như ba via hoặc điền đầy không hoàn chỉnh.

Các hệ thống điều khiển lưu lượng giám sát và điều chỉnh chuyển động vật liệu qua buồng khuôn, đảm bảo phân bố đồng đều và chất lượng sản phẩm nhất quán. Các hệ thống giám sát tiên tiến có thể phát hiện và điều chỉnh các biến đổi ngay lập tức, duy trì dung sai chất lượng nghiêm ngặt trong suốt các đợt sản xuất.

Các quy trình đảm bảo chất lượng và thử nghiệm

Kiểm soát Chất lượng Trong Quá Trình

Thực hiện các biện pháp kiểm soát chất lượng mạnh mẽ trong suốt quá trình đúc phun tùy chỉnh là điều cần thiết để duy trì các tiêu chuẩn cao. Điều này bao gồm kiểm tra vật liệu thường xuyên, giám sát tham số quy trình và thực hiện kiểm soát quy trình thống kê (SPC). Các cơ sở hiện đại sử dụng các hệ thống kiểm tra tự động và giám sát thời gian thực để phát hiện và giải quyết các vấn đề về chất lượng ngay lập tức.

Các giao thức kiểm soát chất lượng nên bao gồm kiểm tra thường xuyên độ chính xác kích thước, kết thúc bề mặt và tính chất vật liệu. Các công nghệ đo lường tiên tiến như máy đo tọa độ (CMM) và hệ thống quét quang đảm bảo xác minh chất lượng chính xác.

Kiểm tra và xác nhận sau sản xuất

Sau sản xuất, việc kiểm tra toàn diện nhằm xác nhận chất lượng và chức năng của bộ phận. Quá trình này bao gồm phân tích kích thước, thử nghiệm cơ học và thử nghiệm chịu lực môi trường khi cần thiết. Việc lưu trữ tài liệu kết quả kiểm tra và duy trì hồ sơ chất lượng chi tiết đảm bảo khả năng truy xuất nguồn gốc và hỗ trợ các nỗ lực cải tiến liên tục.

Việc xác nhận sau sản xuất cũng có thể bao gồm các thử nghiệm lão hóa nhanh, thử nghiệm khả năng chịu hóa chất và xác minh hiệu suất trong điều kiện sử dụng mô phỏng. Những đánh giá kỹ lưỡng này khẳng định sản phẩm đáp ứng mọi yêu cầu đã nêu và duy trì độ tin cậy trong các ứng dụng dự định.

Bền vững và Xu hướng Tương lai

Các cân nhắc về môi trường

Các hoạt động đúc phun tùy chỉnh hiện đại ngày càng tập trung vào tính bền vững. Điều này bao gồm triển khai các chương trình tái chế, sử dụng thiết bị tiết kiệm năng lượng và tìm kiếm các vật liệu sinh học. Các nhà sản xuất đang áp dụng hệ thống vòng kín để giảm thiểu chất thải và giảm tác động đến môi trường trong khi vẫn duy trì chất lượng sản phẩm.

Các công nghệ tái chế tiên tiến cho phép tái sử dụng hiệu quả các vật liệu mà không làm giảm chất lượng. Các hệ thống quản lý năng lượng tối ưu hóa mức tiêu thụ điện trong quá trình sản xuất, góp phần vào tính bền vững môi trường và hiệu quả về chi phí.

Tích hợp Industry 4.0

Tương lai của ngành ép phun tùy chỉnh nằm ở sản xuất thông minh và tích hợp Công nghiệp 4.0. Các hệ thống kết nối, khả năng trí tuệ nhân tạo và học máy đang cách mạng hóa việc kiểm soát quy trình và quản lý chất lượng. Những công nghệ này cho phép bảo trì dự đoán, kiểm soát chất lượng tự động và tối ưu hóa quy trình theo thời gian thực.

Công nghệ mô hình số (digital twin) và phân tích dữ liệu nâng cao cung cấp những hiểu biết chưa từng có về quy trình sản xuất, cho phép cải tiến liên tục và nâng cao kiểm soát chất lượng. Việc tích hợp robot và các hệ thống xử lý tự động còn cải thiện độ nhất quán và giảm sai sót do con người.

Các câu hỏi thường gặp

Những yếu tố chính nào ảnh hưởng đến chất lượng ép phun tùy chỉnh?

Các yếu tố chính ảnh hưởng đến chất lượng trong gia công khuôn ép phun tùy chỉnh bao gồm lựa chọn vật liệu, thiết kế khuôn, kiểm soát nhiệt độ, quản lý áp suất và tính nhất quán của quá trình. Thiết bị hiện đại, bảo trì đúng cách và người vận hành có tay nghề cũng đóng vai trò quan trọng trong việc đạt được kết quả chất lượng cao.

Các nhà sản xuất có thể giảm thiểu khuyết tật trong các bộ phận ép phun tùy chỉnh bằng cách nào?

Các nhà sản xuất có thể giảm khuyết tật bằng cách thực hiện kiểm soát quy trình phù hợp, duy trì các thông số nhiệt độ và áp suất tối ưu, đảm bảo bảo trì khuôn đúng cách và sử dụng các hệ thống giám sát tiên tiến. Việc kiểm tra chất lượng định kỳ và tối ưu hóa liên tục quy trình cũng rất cần thiết để giảm thiểu khuyết tật.

Việc lựa chọn vật liệu đóng vai trò gì trong thành công của quá trình ép phun tùy chỉnh?

Việc lựa chọn vật liệu rất quan trọng vì nó ảnh hưởng đến hiệu suất của chi tiết, các thông số gia công và chất lượng tổng thể. Vật liệu được chọn phải đáp ứng các yêu cầu cơ học, điều kiện gia công và đặc điểm kỹ thuật cho mục đích sử dụng cuối cùng, đồng thời phải tương thích với thiết bị đúc và các thông số thiết kế.

Tự động hóa cải thiện chất lượng đúc phun tùy chỉnh như thế nào?

Tự động hóa nâng cao chất lượng bằng cách cung cấp kiểm soát quá trình ổn định, giảm sai sót do con người và cho phép giám sát và điều chỉnh theo thời gian thực. Các hệ thống tự động có thể duy trì các thông số chính xác, thực hiện kiểm tra chất lượng định kỳ và điều chỉnh các điều kiện gia công để tối ưu hóa chất lượng đầu ra.

Mục Lục

- Làm Chủ Nghệ Thuật Sản Xuất Chính Xác Thông Qua Ép Phun Khuôn

- Các Thành Phần Thiết Yếu Của Thành Công Trong Gia Công Khuôn Ép Phun Tùy Chỉnh

- Kiểm soát Quy trình Nâng cao và Tối ưu hóa

- Các quy trình đảm bảo chất lượng và thử nghiệm

- Bền vững và Xu hướng Tương lai

-

Các câu hỏi thường gặp

- Những yếu tố chính nào ảnh hưởng đến chất lượng ép phun tùy chỉnh?

- Các nhà sản xuất có thể giảm thiểu khuyết tật trong các bộ phận ép phun tùy chỉnh bằng cách nào?

- Việc lựa chọn vật liệu đóng vai trò gì trong thành công của quá trình ép phun tùy chỉnh?

- Tự động hóa cải thiện chất lượng đúc phun tùy chỉnh như thế nào?