Evaluating Technical Expertise in OEM Molding Manufacturers

Material Specialization for Plastic End Cap OEM Projects

Specializing in materials matters a lot when working on OEM projects, especially when making plastic end caps since this directly affects how long they last and how well they perform. Get the materials wrong and products might hold up under stress or break down way too soon. Most manufacturers go with either polyethylene or polypropylene for these end caps because both have useful characteristics. They stand up against chemicals, stay light weight, and generally handle rough treatment pretty well. Polypropylene stands out for being flexible and resisting most chemicals, whereas polyethylene handles impacts better and keeps moisture out effectively. Standards organizations like ASTM and ISO provide helpful guidance for matching materials to quality requirements so the finished end caps actually meet those tough performance specs. Picking the right stuff makes all the difference in how long things last and work properly across different environments.

Advanced Machinery for Mould Plastics Machine Operations

How well plastic molding works, especially when making things like those plastic end caps we see everywhere, really hinges on what kind of machinery is being used. Injection molding machines are pretty amazing at creating all sorts of complicated shapes with good accuracy. The latest tech trends focus heavily on automation and getting even better precision, something that helps cut down on wasted material while speeding things up. When factories automate their processes and install computer controls, products tend to come out looking the same every time and production runs faster too. According to folks who know the industry inside out, spending money on state-of-the-art equipment pays off big time in terms of both quantity produced and overall quality. Take a look at recent research findings showing that companies using digital systems in their machines experience fewer hiccups during operation and get much better results from their molds. This means not just saving money but also reducing environmental impact over time. Manufacturers jumping on board with these newer technologies generally find themselves producing more usable parts with fewer defects, which translates directly into better bottom line numbers.

Assessing Production Capabilities and Scalability

Custom Plastic Injection Molding Solutions

Custom plastic injection molding plays a key role in developing specialized products for many different sectors, helping businesses fulfill their particular design needs and functional goals. The process works by carefully working with materials according to what each project demands, which makes the final products work better and look good for whatever they're meant to do. Take the automotive sector for example where custom molds let car makers craft intricate components that slot right into today's vehicles, making them perform better and feel nicer to drive. When companies offer these made-to-order options, customers tend to be happier and stick around longer. We've seen this happen time and again in real world situations where people engage more with products that just fit better and actually work as promised.

High-Volume vs. Low-Volume Manufacturing Flexibility

Choosing between high volume and low volume production isn't just important it's absolutely essential for manufacturers these days. When companies go with high volume manufacturing they can save money when demand spikes, but this approach doesn't leave much room for changes. On the flip side, smaller production batches let factories respond faster to market shifts and offer custom options to customers. Most manufacturers struggle to find the sweet spot between these extremes as customer demands keep changing. Industry data shows something interesting happening though there seems to be a movement toward more customized manufacturing methods that meet what specific OEMs need. This flexibility helps keep production plans relevant in today's fast moving markets, and many OEM clients now expect their suppliers to provide specialized manufacturing solutions rather than one size fits all approaches.

Integration of Automation in Moulding Processes

Automated systems have become pretty much necessary if companies want to keep their molding processes efficient and consistent across batches. Manufacturers are bringing in robots and artificial intelligence solutions all over the shop floor these days. These tech upgrades help speed things up while cutting down on mistakes made by workers and making better use of materials. Take AI systems for instance they actually learn when machines start showing signs of wear and tear, so maintenance crews can fix problems before they cause big headaches. This means less time wasted waiting for repairs and smoother running operations overall. Companies that don't adopt some form of automation risk falling behind competitors who've already seen real gains in both what they produce and how much money stays in their pockets at month end.

Quality Assurance and Certifications

ISO 13485 Compliance for Medical Device Molding

For medical device makers, sticking to ISO 13485 standards isn't just good practice—it's essential throughout every operation stage. Getting certified shows a company really cares about making products that meet top quality and safety benchmarks, something absolutely vital when lives depend on those devices. These regulations help firms set up comprehensive quality systems covering everything from vetting suppliers right through to managing potential risks during production. Take MedAccred as one example among others who have nailed this compliance thing down pat. Regular checks by independent certifiers keep things honest too, giving original equipment manufacturers and patients peace of mind knowing their gear meets strict requirements consistently over time.

In-Process Testing and Defect Prevention Strategies

Maintaining good quality during manufacturing means OEMs use several tests while products are being made to catch problems before they become big issues. Common techniques include things like statistical process control (SPC), automated optical inspection (AOI), and systems that monitor production in real time. These help spot irregularities so fixes can happen before thousands of units roll off the line. Preventing defects from happening at all cuts down on failed products and wasted materials, which makes everything more reliable overall. Industry data shows defect rates drop around 30% when companies stick with regular testing throughout production. For many manufacturers, investing in these kinds of checks isn't just about meeting standards it's becoming essential for staying competitive in today's market where customers expect perfection.

Industry Experience and Medical Device Focus

Case Studies in Class III Medical Component Production

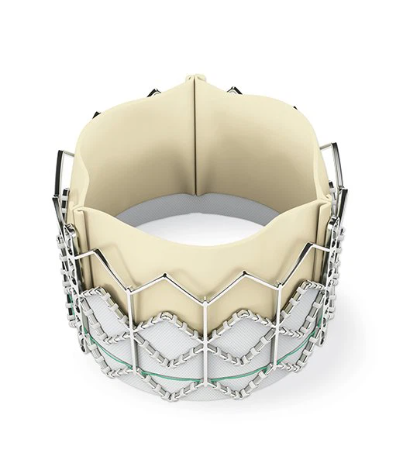

Making Class III medical parts presents all sorts of complicated challenges that need creative problem solving and strict adherence to regulations. Looking at different real world situations shows how companies actually tackle these problems using flexible approaches and careful engineering work. The rules governing Class III components are extremely strict since they cover life saving equipment, so there has to be thorough testing and quality checks throughout development to keep patients safe. Take heart valve replacements for example many manufacturers now use sophisticated computer models along with extensive prototype testing just to satisfy FDA requirements. What stands out from these cases isn't just the difficulties faced but also the smart improvements made regarding materials used, faster production methods, and better overall reliability, leading directly to medical devices that work better and pose fewer risks. Anyone who looks closely at these industry stories will quickly realize that beating both regulatory roadblocks and technical obstacles remains essential if anyone wants to successfully bring Class III medical devices to market.

Adapting to Regulatory Changes in Healthcare Manufacturing

Healthcare manufacturing keeps changing fast because of all the new regulations affecting OEM mold makers. The latest rule changes focus on making things safer for patients while improving how well medical products work. Companies need to adjust their operations constantly if they want to stay within legal boundaries and keep up with competitors. Take automation technology as an example many factories now install automated systems alongside real time monitoring equipment so they can adapt faster when rules change without shutting down production lines completely. Industry insiders point out that adopting these tech solutions does more than meet legal standards it actually makes factory workflows smoother and cuts down on wasted time during production runs. Going beyond mere compliance means positioning themselves ahead of others in terms of innovation and quality standards across healthcare manufacturing sectors. When businesses implement smart strategies from day one, they find themselves better equipped to handle complicated regulatory landscapes while maintaining top positions in their markets despite ongoing challenges posed by ever shifting compliance demands.

Communication and Supply Chain Transparency

Real-Time Project Tracking Systems

Real time project tracking systems for OEM molding processes bring quite a few advantages to the table. These kinds of systems basically make everything visible since they give current info about where projects stand at any given moment. When customers can see what's going on with their orders, they tend to trust the company more and generally feel better about working together, which helps build those lasting business relationships over time. Another big plus is that such tracking allows businesses to spot problems before they become major issues. Companies can catch delays early and fix whatever might be slowing things down, so deadlines stay intact and product quality remains consistent throughout production runs. Most molders rely on software solutions these days. Tools like Asana, Trello, and Microsoft Project have become pretty standard across the industry because they offer all sorts of features specifically designed for manufacturing environments. Some folks even tweak these platforms to fit their particular workflow needs.

Multilingual Support for Global Partnerships

Multilingual support has become essential in our interconnected world where businesses operate across borders. When people speak different languages, it creates real problems for projects getting done on time and meeting quality standards. That's why having staff who can communicate in multiple languages matters so much these days. Good communication keeps everyone aligned, cuts down on confusion, and makes teamwork actually work. Take big companies operating worldwide as an example they tend to finish projects better when their teams can talk directly rather than relying solely on translations. Research shows firms that hire bilingual employees or spend money on professional translation services generally perform better than those that don't bother. The bottom line? If a company wants to succeed internationally, investing in language capabilities isn't just nice to have it's becoming a necessity.

FAQ

What are the key materials used in plastic end cap production?

Polyethylene and polypropylene are key materials used in plastic end cap production due to their robust chemical resistance, lightweight nature, and impact strength.

How does automation impact the molding process?

Automation enhances molding processes by improving efficiency, consistency, and precision, thus reducing human error and resource waste.

Why is ISO 13485 compliance important for medical device molding?

ISO 13485 compliance ensures high standards of product quality and safety in medical device production, critical for maintaining patient well-being.

What is the significance of multilingual support in global partnerships?

Multilingual support is significant for overcoming language barriers, enhancing communication, and fostering effective collaboration in global partnerships.

Table of Contents

-

Evaluating Technical Expertise in OEM Molding Manufacturers

- Material Specialization for Plastic End Cap OEM Projects

- Advanced Machinery for Mould Plastics Machine Operations

- Assessing Production Capabilities and Scalability

- Custom Plastic Injection Molding Solutions

- High-Volume vs. Low-Volume Manufacturing Flexibility

- Integration of Automation in Moulding Processes

- Quality Assurance and Certifications

- ISO 13485 Compliance for Medical Device Molding

- In-Process Testing and Defect Prevention Strategies

- Industry Experience and Medical Device Focus

- Case Studies in Class III Medical Component Production

- Adapting to Regulatory Changes in Healthcare Manufacturing

- Communication and Supply Chain Transparency

- Real-Time Project Tracking Systems

- Multilingual Support for Global Partnerships

- FAQ