De productielandschap heeft de afgelopen decennia opmerkelijke transformaties doorgemaakt, waarbij spuitgieten is uitgegroeid tot een van de meest cruciale productieprocessen in diverse industrieën. Van auto-onderdelen tot medische apparatuur, consumentenelektronica tot verpakkingsoplossingen: de vraag naar precisie-engineered kunststofproducten blijft wereldwijd sterk groeien. Om te begrijpen wat de toonaangevende fabrikanten in deze concurrerende sector onderscheidt, dient men hun technologische capaciteiten, kwaliteitscontrolesystemen en strategische benadering van innovatie te bestuderen.

De spuitgietindustrie vormt een hoeksteen van de moderne productie en genereert jaarlijks miljarden dollars aan omzet, terwijl ze talloze afhankelijke industrieën ondersteunt. Toonaangevende fabrikanten onderscheiden zich door hun vermogen om consistent hoogwaardige producten te leveren tegen concurrerende prijzen en met efficiënte productieplanning. Deze marktleiders hebben forse investeringen gedaan in geavanceerde technologie, ontwikkeling van een gespecialiseerde arbeidskracht en uitgebreide kwaliteitsmanagementsystemen die garanderen dat elk spuitgietproduct voldoet aan strikte specificaties.

De marktdynamiek blijft zich snel ontwikkelen, gedreven door toenemende consumentenverwachtingen, milieuregels en technologische vooruitgang. Succesvolle fabrikanten moeten deze uitdagingen het hoofd bieden terwijl ze tegelijkertijd kansen grijpen in opkomende sectoren zoals elektrische voertuigen, hernieuwbare energie en geavanceerde gezondheidsoplossingen. De bedrijven die bloeien in deze omgeving, tonen een uitzonderlijke aanpassingsvatbaarheid en toekomstgerichte strategieën die hen positioneren voor duurzame groei.

Geavanceerde productietechnologieën en apparatuur

Staat-van-de-kunst spuitgietmachines

Toonaangevende fabrikanten onderscheiden zich door strategische investeringen in de nieuwste spuitgietapparatuur, uitgerust met geavanceerde regelsystemen, verbeterde precisie en hogere energieëfficiëntie. Deze geavanceerde machines maken het mogelijk complexe geometrieën met nauwe toleranties te produceren, wat zorgt voor een consistente kwaliteit tijdens grote productieruns. Moderne apparatuur is voorzien van real-time bewakingssystemen die kritieke parameters zoals temperatuur, druk en cyclus tijden volgen, zodat operators direct kunnen ingrijpen wanneer afwijkingen optreden.

De integratie van servoaangedreven systemen heeft het productieproces gereset, met een superieure snelheidsregeling en energie-efficiëntie vergeleken met traditionele hydraulische systemen. Deze technologische verbeteringen leiden direct tot een betere productkwaliteit, minder verspilling en lagere bedrijfskosten. Toonaangevende fabrikanten geven de voorkeur aan apparatuur met modulaire configuraties, waardoor snel kan worden overgeschakeld tussen verschillende productspecificaties zonder in te boeten aan productie-efficiëntie.

Integratie van Automatisering en Robotica

Automatisering speelt een cruciale rol in moderne spuitgietprocessen, waarbij toonaangevende fabrikanten uitgebreide robotsystemen inzetten voor materiaalhantering, kwaliteitsinspectie en verpakkingsprocessen. Deze geautomatiseerde oplossingen verlagen de kans op menselijke fouten, vergroten de consistentie van de productie en maken continu bedrijf (24/7) mogelijk. Geavanceerde robotsystemen kunnen complexe taken uitvoeren zoals het plaatsen van inzetstukken, overlappende gietoperaties en meertraps assemblageprocessen met uitzonderlijke precisie.

De toepassing van collaboratieve robots, ofwel cobots, heeft de flexibiliteit in de productie verder verbeterd doordat medewerkers veilig samen kunnen werken met geautomatiseerde systemen. Deze hybride aanpak optimaliseert de productie-efficiëntie en behoudt tegelijkertijd de aanpassingsvatbaarheid die nodig is voor op maat gemaakte toepassingen en snelle prototypeontwikkeling. Toonaangevende fabrikanten blijven onderzoeken hoe opkomende technologieën zoals kunstmatige intelligentie en machine learning hun geautomatiseerde processen verder kunnen optimaliseren.

Kwaliteitscontrole en certificatiestandaarden

Alomvattende Kwaliteitsbeheersysteem

Uitstekende fabrikanten passen robuuste kwaliteitsmanagementsystemen toe die elk aspect van het productieproces omvatten, van inspectie van grondstoffen tot validatie van het eindproduct. Deze systemen voldoen meestal aan internationale normen zoals ISO 9001, waardoor een consistente kwaliteit over alle activiteiten heen wordt gewaarborgd. Geavanceerde kwaliteitscontroleprotocollen omvatten statistische procesregelmethoden die productievariabelen in real-time monitoren, zodat proactieve aanpassingen mogelijk zijn voordat kwaliteitsproblemen ontstaan.

De integratie van geavanceerde meet- en testapparatuur maakt een uitgebreide evaluatie mogelijk van dimensionele nauwkeurigheid, materiaaleigenschappen en functionele prestaties. Toonaangevende bedrijven investeren in coördinatenmeetmachines, geautomatiseerde optische inspectiesystemen en materialentestlaboratoria om te verifiëren dat elk spuitgietproduct voldoet aan de gespecificeerde eisen. Deze toewijding aan kwaliteitsuitmuntendheid vergroot het klantvertrouwen en ondersteunt langdurige zakelijke relaties.

Sectorgebonden certificeringen

Topfabrikanten streven vaak gespecialiseerde certificeringen na die relevant zijn voor hun doelmarkten, zoals ISO 13485 voor medische hulpmiddelen, TS 16949 voor automotive toepassingen of FDA-conformiteit voor producten die in contact komen met voedsel. Deze certificeringen tonen een engagement aan ten aanzien van sectorale best practices en naleving van regelgeving, en geven toegang tot hoogwaardige marktsegmenten. Het certificeringsproces vereist uitgebreide documentatie, regelmatige audits en initiatieven voor continue verbetering die de algehele operationele excellentie verhogen.

Het behoud van meerdere certificeringen vereist een forse investering in opleiding, documentatie en processtandaardisatie, maar de resulterende concurrentievoordelen rechtvaardigen deze kosten. Gecertificeerde fabrikanten kunnen toegang krijgen tot premium marktsegmenten, hogere prijzen vragen voor hun producten en sterkere relaties opbouwen met kwaliteitsbewuste klanten die betrouwbaarheid en conformiteit van leveranciers belangrijk vinden.

Materiaalkunde en Innovatie

Advanced Polymer Technologies

Toonaangevende fabrikanten van spuitgietmatrijzen beschikken over uitgebreide expertise in polymeerwetenschap, waardoor ze optimale materialen kunnen selecteren voor specifieke toepassingen en verwerkingsvereisten. Deze kennis omvat het begrip van materiaaleigenschappen, verwerkingseigenschappen en verwachtingen met betrekking tot langdurige prestaties. Geavanceerde fabrikanten werken vaak samen met materiaalleveranciers om op maat gemaakte formuleringen te ontwikkelen die voldoen aan unieke klantvereisten of de productprestaties verbeteren.

De ontwikkeling van hoogwaardige technische kunststoffen heeft nieuwe kansen geopend in veeleisende toepassingen zoals lucht- en ruimtevaart, medische implantaatmaterialen en elektronische componenten. Toonaangevende fabrikanten investeren in materiaaltestmogelijkheden en beschikken over uitgebreide bibliotheken met materiaalgegevens om de ontwerpprocessen van klanten te ondersteunen en een optimale materiaalkeuze voor elke toepassing te waarborgen.

Duurzame materiaallooplossingen

Milieubewustzijn is een cruciaal differentiatieelement geworden, waarbij toonaangevende fabrikanten actief duurzame materiaaloplossingen en principes van de circulaire economie nastreven. Dit omvat het gebruik van gerecycled materiaal, biologisch afbreekbare polymeren en op biologische grondstoffen gebaseerde materialen die de milieubelasting verminderen zonder afbreuk te doen aan de prestaties. Geavanceerde recyclagetechnologieën maken het mogelijk om afvalstromen uit consumptie en industrie te verwerken in nieuwe producten.

Duurzame praktijken gaan verder dan de keuze van materialen en omvatten energie-efficiënte verwerking, initiatieven ter vermindering van afval en overwegingen rond het einde van de levensduur van producten. Fabrikanten die een echte inzet tonen voor milieubeheer, verkrijgen vaak concurrentievoordelen op markten waar duurzaamheid steeds meer wordt gewaardeerd door consumenten en regelgevende instanties.

Ontwerp- en engineeringmogelijkheden

Geavanceerde diensten voor productontwikkeling

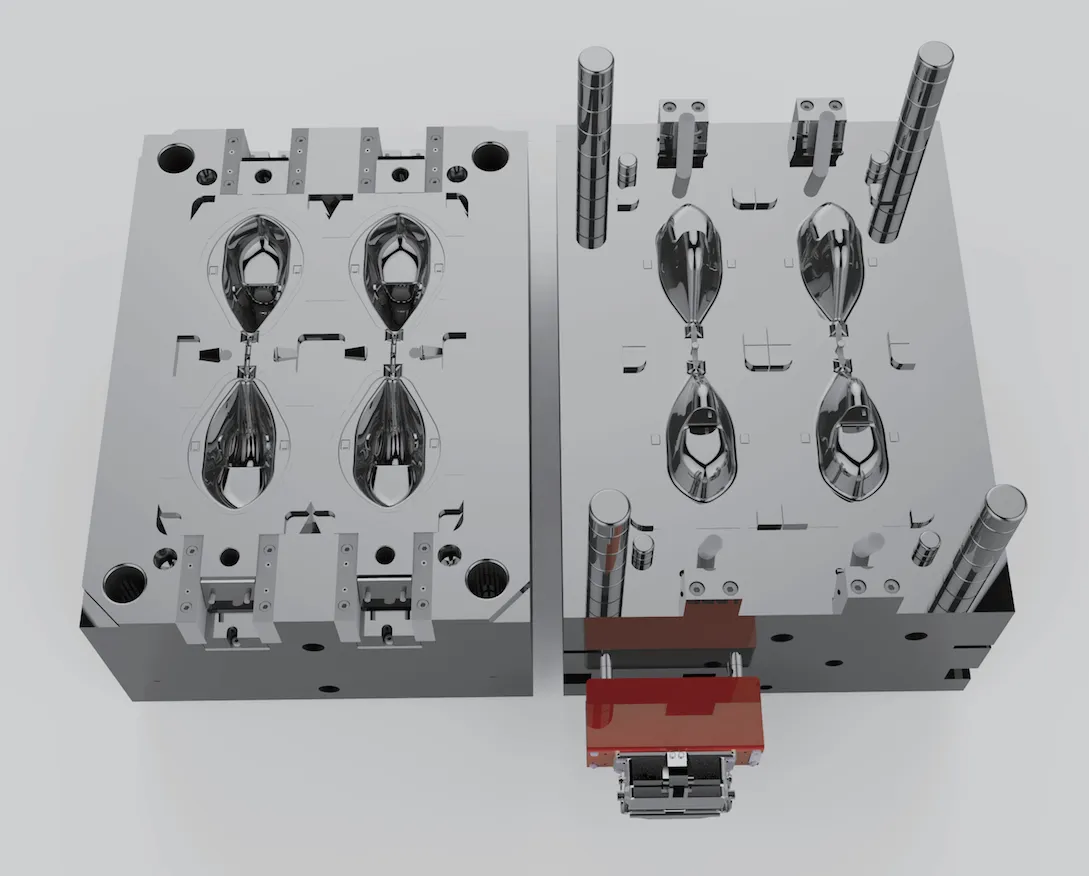

Uitzonderlijke fabrikanten bieden uitgebreide ontwerp- en engineeringdiensten die klanten ondersteunen gedurende de gehele productontwikkelingscyclus. Deze diensten omvatten ontwerp voor fabricage-analyse, optimalisatie van matrijzenontwerp en prototypingmogelijkheden. Geavanceerde computerondersteunde ontwerpprogramma's en simulatietools stellen engineers in staat om de productprestaties te voorspellen en te optimaliseren voordat fysiek prototyping begint.

De mogelijkheid om geïntegreerde oplossingen aan te bieden van concept tot productie, geeft toonaangevende fabrikanten aanzienlijke concurrentievoordelen. Klanten profiteren van gestroomlijnde ontwikkelprocessen, verkorte time-to-market en geoptimaliseerde ontwerpen die productiekosten minimaliseren terwijl de prestaties worden gemaximaliseerd. Deze toegevoegde diensten staan vaak garant voor hogere prijzen en bevorderen langdurige klantrelaties.

Snelle prototypen en gereedschapsbouw

Snel naar de markt komen is steeds kritischer geworden in competitieve sectoren, waardoor snelle prototypingmogelijkheden essentieel zijn voor toonaangevende fabrikanten. Geavanceerde prototypingtechnologieën zoals 3D-printen, CNC-bewerking en snel gereedschap maken snelle validatie van ontwerpopvattingen en versnelde ontwikkelcycli mogelijk. Deze mogelijkheden stellen klanten in staat hun producten te testen en verfijnen voordat ze investeren in volledige productiegereedschappen.

Investeringen in snel gereedschapstechnologieën, inclusief aluminiumgereedschap en additieve productiemethoden, maken kosteneffectieve productie in kleine oplagen en marktvalidatie mogelijk. Deze flexibiliteit ondersteunt klanten bij het testen van nieuwe marktkansen en vermindert het financiële risico dat gepaard gaat met het introduceren van nieuwe producten.

Supply Chain Management en wereldwijde bereikbaarheid

Strategische leveringsketenpartnerschappen

Toonaangevende fabrikanten ontwikkelen robuuste supply chain-netwerken die zorgen voor betrouwbare toegang tot hoogwaardige grondstoffen en componenten. Deze samenwerkingen omvatten vaak langetermijnovereenkomsten met leveranciers van materialen, logistieke dienstverleners en secundaire serviceproviders die de productieplanning en kwaliteitsnormen ondersteunen. Strategische leveranciersrelaties maken gunstigere prijzen, prioriteitstoegang tot nieuwe materialen en gezamenlijke ontwikkeling van innovatieve oplossingen mogelijk.

Geavanceerde supply chainmanagementsystemen bieden realtime inzicht in beschikbaarheid van materialen, prijstrends en leveringschema's. Deze transparantie stelt bedrijven in staat proactief beslissingen te nemen en risico's te beperken, waardoor productiestoringen worden vermeden en het klantenservicepeil wordt gehandhaafd. Toonaangevende bedrijven onderhouden vaak meerdere leveranciersrelaties voor kritieke materialen om de continuïteit van de aanvoer te waarborgen.

Wereldwijde productie en distributie

Internationale aanwezigheid is steeds belangrijker geworden voor het bedienen van multinationale klanten en toegang tot wereldwijde markten. Toonaangevende fabrikanten richten productiefaciliteiten op strategische locaties in, die kostenvoordelen opleveren, dichtbij belangrijke klanten liggen en toegang bieden tot gespecialiseerde expertise. Deze wereldwijde voetafdruk zorgt voor een snelle klantenservice, lagere transportkosten en naleving van lokale regelgeving.

Doeltreffende coördinatie tussen meerdere faciliteiten vereist geavanceerde informatiesystemen en genormaliseerde processen die overal ter wereld een consistente kwaliteit en servicelevels garanderen. Toonaangevende bedrijven investeren forse bedragen in communicatietechnologieën en managementsystemen die naadloze samenwerking tussen teams wereldwijd mogelijk maken.

Klantenservice Dienst en technische ondersteuning

Algemene technische ondersteuning

Uitstekende klantenservice onderscheidt toonaangevende fabrikanten door hun vermogen om deskundige technische ondersteuning te bieden gedurende de gehele levenscyclus van het product. Deze ondersteuning omvat toepassingsengineering, probleemoplossing en aanbevelingen voor voortdurende optimalisatie. Technische ondersteuningsteams beschikken over diepgaande expertise in spuitgietprocessen, materiaalkunde en toepassingsspecifieke eisen, waardoor ze in staat zijn complexe klantvraagstukken op te lossen.

Proactieve klantcommunicatie omvat regelmatige prestatiebeoordelingen, aanbevelingen voor preventief onderhoud en updates over nieuwe technologieën of materialen die van nut kunnen zijn voor klanttoepassingen. Deze consultatieve aanpak versterkt de klantrelaties en positioneert fabrikanten als vertrouwde partners in plaats van simpele leveranciers.

Flexibele productie- en leveringsopties

Marktgerichtheid vereist flexibele productiecapaciteiten die kunnen omgaan met wisselende vraagpatronen, specifieke klantwensen en dringende leveringschema's. Toonaangevende fabrikanten behouden flexibiliteit in productiecapaciteit via modulaire apparatuurconfiguraties, cross-gekwalificeerd personeel en efficiënte planningssystemen. Deze flexibiliteit stelt hen in staat snel te reageren op klantverzoeken en marktkansen.

Geavanceerde voorraadbeheer- en logistieksystemen ondersteunen just-in-time leveringseisen terwijl tegelijkertijd optimale voorraadniveaus worden gehandhaafd. Deze systemen omvatten vaak klantspecifieke voorraadprogramma's, geautomatiseerde navulsystemen en snelle verzendopties die het gemak en de tevredenheid van de klant verbeteren.

Veelgestelde vragen

Welke factoren moeten bedrijven overwegen bij het kiezen van een fabrikant voor spuitgieten?

Bedrijven moeten de productiecapaciteiten, kwaliteitscertificeringen, technische expertise en productiecapaciteit beoordelen bij het kiezen van een partner voor spuitgieten. Belangrijke aspecten zijn de geavanceerdheid van de apparatuur, materiaalverwerkingsmogelijkheden, kwaliteitscontrolesystemen en de staat van dienst van de fabrikant in vergelijkbare toepassingen. Daarnaast dient men hun ontwerpondersteuningsdiensten, stabiliteit van de supply chain en vermogen om productie op te schalen volgens vraagfluctuaties te beoordelen.

Hoe zorgen toonaangevende fabrikanten voor consistente kwaliteit tijdens productieloppen met hoge volumes?

Topfabrikanten implementeren uitgebreide systemen voor statistische procesbeheersing die kritieke parameters in real-time bewaken gedurende de gehele productiecyclus. Zij maken gebruik van geavanceerde meetapparatuur, geautomatiseerde inspectiesystemen en gedocumenteerde kwaliteitsprocedures om consistentie te waarborgen. Regelmatige kalibratie van apparatuur, voortdurende bedienertraining en systematische analyse van kwaliteitsgegevens zorgen voor continue verbetering en vroege detectie van mogelijke problemen voordat deze de productkwaliteit beïnvloeden.

Welke rol speelt automatisering in moderne spuitgietoperaties?

Automatisering verbetert de productie-efficiëntie, consistentie en veiligheid, terwijl de arbeidskosten en menselijke fouten worden verlaagd in spuitgietprocessen. Moderne installaties integreren robotsystemen voor het hanteren van materialen, het verwijderen van onderdelen, kwaliteitsinspectie en verpakkingsprocessen. Geavanceerde automatisering maakt 24/7-productie, nauwkeurige herhaalbaarheid en het kunnen uitvoeren van complexe meerstapscprocessen mogelijk. Deze technologie levert ook waardevolle productiegegevens die continuïteitverbeteringsinitiatieven ondersteunen.

Hoe beïnvloeden milieuoogmerken de praktijken in de spuitgietindustrie?

Milieuduurzaamheid is een cruciale factor geworden die innovatie stimuleert op het gebied van materialen, processen en afvalbeheer. Toonaangevende fabrikanten maken gebruik van gerecycleerde en op biobasis vervaardigde materialen, implementeren energiezuinige apparatuur en ontwikkelen recycling-systemen in gesloten kringlopen. Deze initiatieven zijn een antwoord op wettelijke eisen, klantvragen en bedrijfsdoelstellingen op het vlak van duurzaamheid, en leveren vaak kostenbesparingen op door verminderde materiaalverspilling en lagere energieverbruik.

Inhoudsopgave

- Geavanceerde productietechnologieën en apparatuur

- Kwaliteitscontrole en certificatiestandaarden

- Materiaalkunde en Innovatie

- Ontwerp- en engineeringmogelijkheden

- Supply Chain Management en wereldwijde bereikbaarheid

- Klantenservice Dienst en technische ondersteuning

-

Veelgestelde vragen

- Welke factoren moeten bedrijven overwegen bij het kiezen van een fabrikant voor spuitgieten?

- Hoe zorgen toonaangevende fabrikanten voor consistente kwaliteit tijdens productieloppen met hoge volumes?

- Welke rol speelt automatisering in moderne spuitgietoperaties?

- Hoe beïnvloeden milieuoogmerken de praktijken in de spuitgietindustrie?