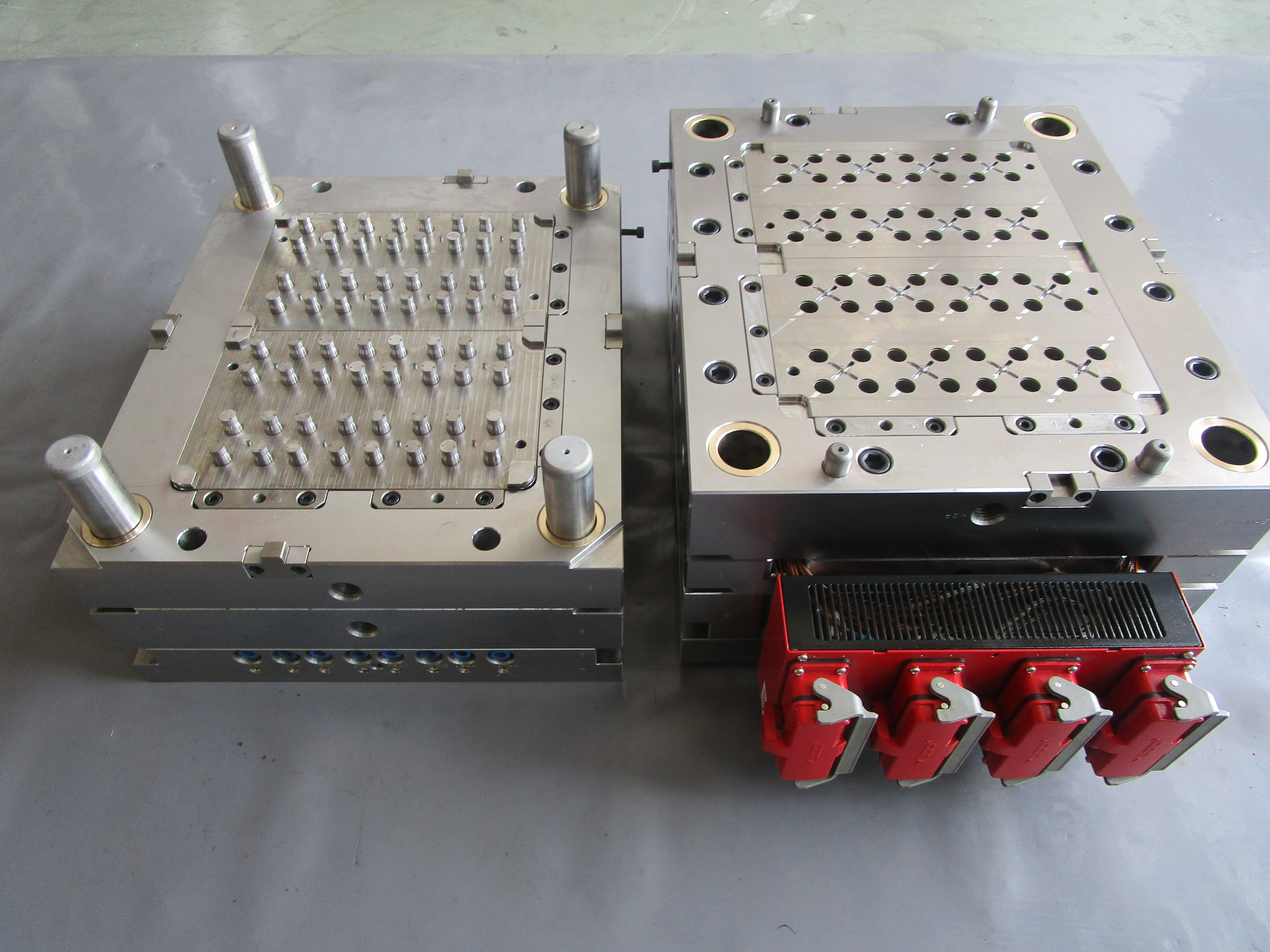

Максимізація виробничої досконалості завдяки рішенням оригінального обладнання. У сучасному конкурентному середовищі виробництва OEM-оснащення набуває все більшої важливості для підприємств, які прагнуть оптимізувати свої виробничі процеси та зберегти конкурентоспроможність...

Дивитися більше

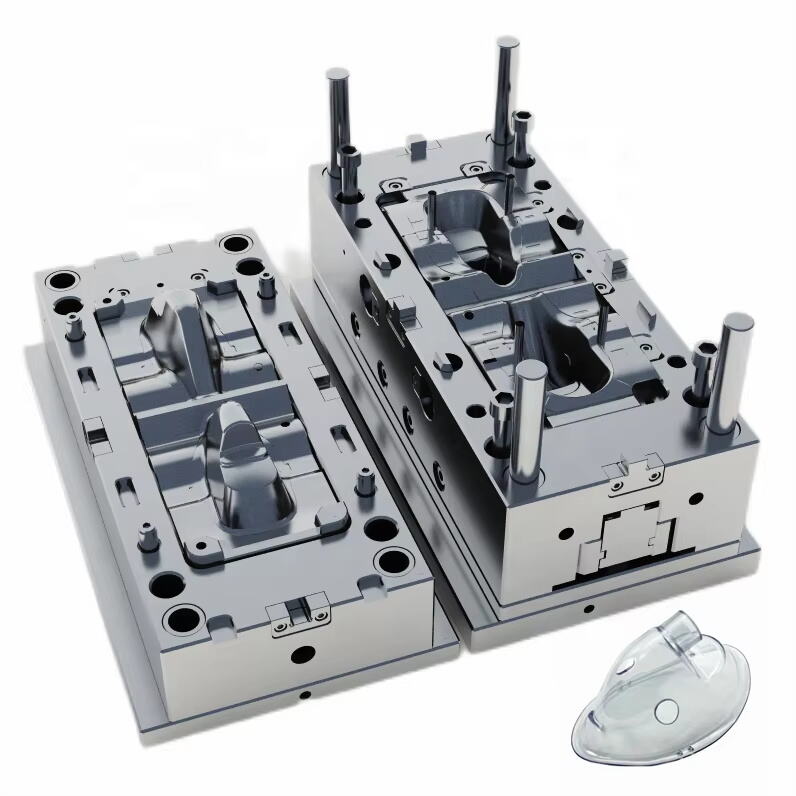

Трансформація охорони здоров'я за допомогою передових технологій формування. Сфера виробництва медичних приладів пройшла революційну трансформацію, спричинену проривовими інноваціями в галузі медичних форм. Ці досягнення змінюють те, як виготовлюються...

Дивитися більше

Розуміння інвестицій у виробництво медичних приладів. Розробка медичних форм є критично важливою складовою виробництва медичного обладнання, що вимагає прецизійної інженерії та суворого дотримання регуляторних стандартів. Складний процес...

Дивитися більше

Ключова роль прецизійної інженерії у виробництві медичних приладів. У складній сфері виробництва медичних приладів, точність у виробництві медичних форм є основою якісного надання медичної допомоги. Складний процес...

Дивитися більше

Розуміння спеціалізованої природи виробництва форм для медичних пристроїв. Індустрія виробництва медичного обладнання вимагає надзвичайної точності, якості та дотримання норм у кожному з вироблених компонентів. Виробництво форм для медичних пристроїв є високоспеціалізованою галуззю...

Дивитися більше

Трансформація охорони здоров’я завдяки сучасним рішенням прототипування. Прототипування медичних пристроїв є критичним етапом між інноваційними концепціями у сфері охорони здоров’я та життєво важливими продуктами, що потрапляють до пацієнтів по всьому світу. Цей складний процес перетворює...

Дивитися більше

Основні переваги партнерств OEM у виробництві медичних пристроїв. Економія коштів за рахунок спільного розподілу ресурсів. Замислюєтеся над тим, щоб укласти партнерські угоди OEM для виробництва медичних пристроїв? Безумовно, існує фінансова вигода, коли мова йде про спільне використання...

Дивитися більше

Біосумісність та безпека пацієнтів: оцінка ризиків токсичності при виборі матеріалів. Дуже важливо знати, чи можуть матеріали медичних пристроїв бути шкідливими, адже це безпосередньо впливає на безпеку пацієнтів. Основна увага приділяється тому, як ці матеріали...

Дивитися більше

Глобальна регуляторна база для виробництва медичних пристроїв. Вимоги FDA щодо виробництва медичних пристроїв. Управління з контролю за харчовими продуктами та лікарськими засобами (FDA) регулює виробництво медичних пристроїв на території США через норми, встановлені у федеральному законі про харчові продукти, ліки...

Дивитися більше

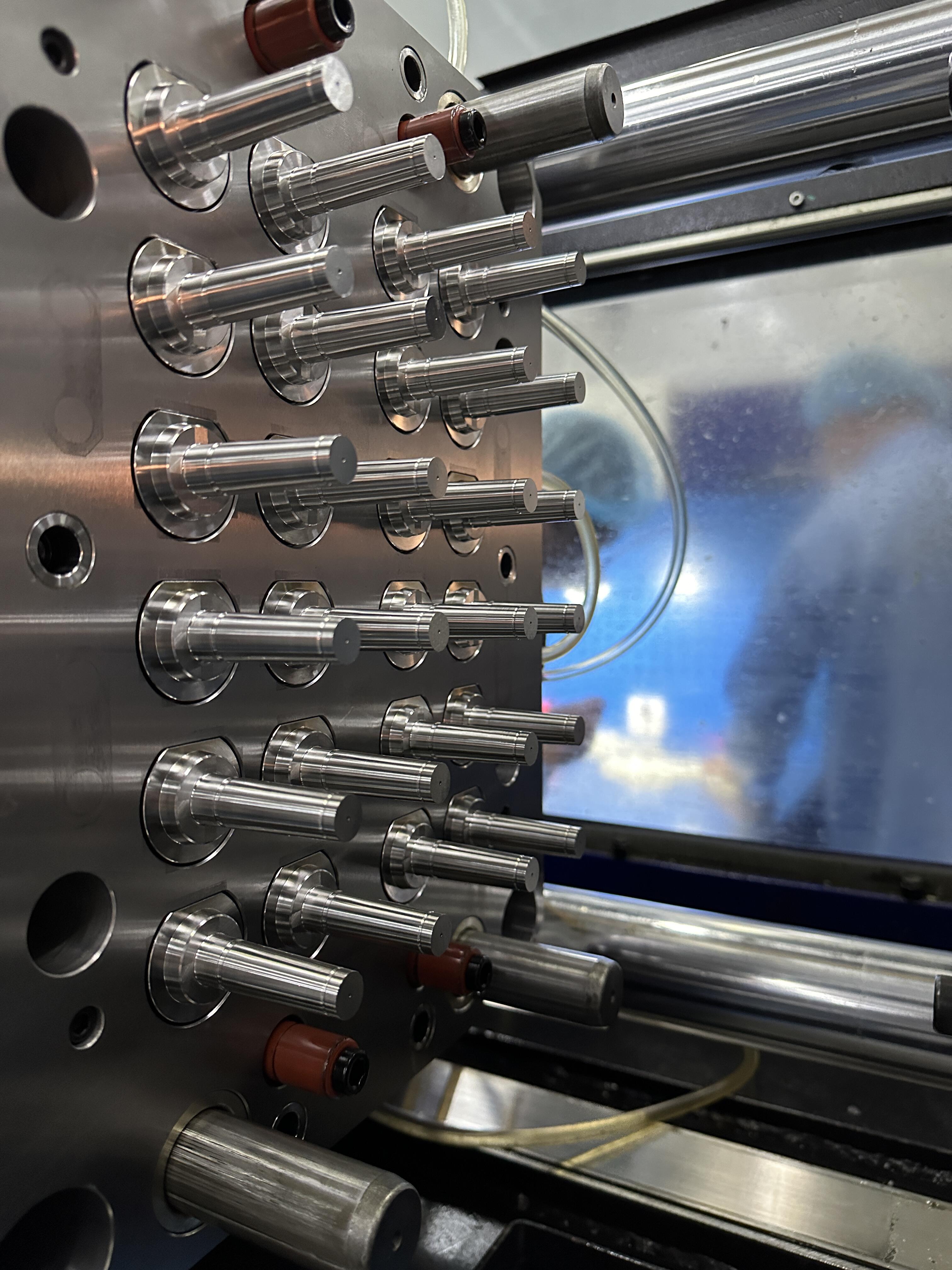

Розуміння компонентів циклу часу ін'єкційного формування. Правильне визначення часу циклу ін'єкційного формування має велике значення для виробничих операцій. Існує чотири основні етапи: ін'єкція, ущільнення, охолодження та, нарешті, виштовхування. Знати...

Дивитися більше

Важливість контролю якості у литті під тиском. Роль у стабільності продукту. У сфері лиття під тиском контроль якості є абсолютно необхідним для забезпечення стабільності продуктів у межах партій. Коли деталі стабільно відповідають встановленим стандартам...

Дивитися більше

Ефективність лиття під тиском у великих обсягах. Зниження вартості одиниці продукції за рахунок масштабованого виробництва. Лиття під тиском відоме здатністю виготовляти великі кількості абсолютно однакових деталей, і робить це з дуже низькою вартістю на одиницю продукції...

Дивитися більше