Revolutionizing Healthcare Through Advanced Prototyping Solutions

Medical device prototyping represents a critical bridge between innovative healthcare concepts and life-saving products that reach patients worldwide. This sophisticated process transforms promising ideas into tangible solutions, enabling medical professionals to deliver better patient care while advancing the boundaries of modern medicine. As healthcare challenges become increasingly complex, the role of medical device prototyping continues to evolve, incorporating cutting-edge technologies and methodologies that accelerate development cycles and enhance product efficacy.

The journey from initial concept to market-ready medical device involves multiple iterations, rigorous testing, and careful adherence to regulatory requirements. Understanding this process is crucial for inventors, medical device companies, and healthcare professionals who aim to bring revolutionary solutions to market. Through strategic prototyping approaches, organizations can significantly reduce development costs, minimize risks, and optimize their products for both regulatory approval and market success.

The Essential Stages of Medical Device Development

Concept Generation and Initial Design

The medical device prototyping process begins with thorough market research and needs assessment. Developers must identify specific healthcare challenges and envision solutions that address these issues effectively. This initial stage involves extensive collaboration between medical professionals, engineers, and design experts to create preliminary sketches and digital models.

During this phase, teams evaluate technical feasibility, market potential, and regulatory requirements. They consider factors such as user interface design, ergonomics, and material selection. Early stakeholder involvement ensures that the final product will meet both clinical needs and user expectations.

Proof of Concept Development

Once the initial design is established, teams move forward with creating proof of concept prototypes. These early models demonstrate the fundamental principles and core functionalities of the proposed device. Through medical device prototyping at this stage, developers can validate their basic assumptions and identify potential challenges before investing in more sophisticated prototypes.

This phase often involves rapid prototyping technologies such as 3D printing, which allows for quick iteration and design refinement. Teams can evaluate multiple design variations and gather valuable feedback from healthcare professionals and potential users.

Advanced Prototyping Technologies and Methods

Digital Design and Simulation

Modern medical device prototyping heavily relies on advanced digital tools and simulation software. Computer-aided design (CAD) programs enable precise modeling of device components, while finite element analysis helps predict mechanical behavior and structural integrity. These digital technologies significantly reduce development time and costs by identifying potential issues before physical prototypes are created.

Virtual testing environments allow developers to simulate various use scenarios and stress conditions, providing valuable insights into product performance and reliability. This digital-first approach helps optimize designs and minimize the number of physical prototype iterations required.

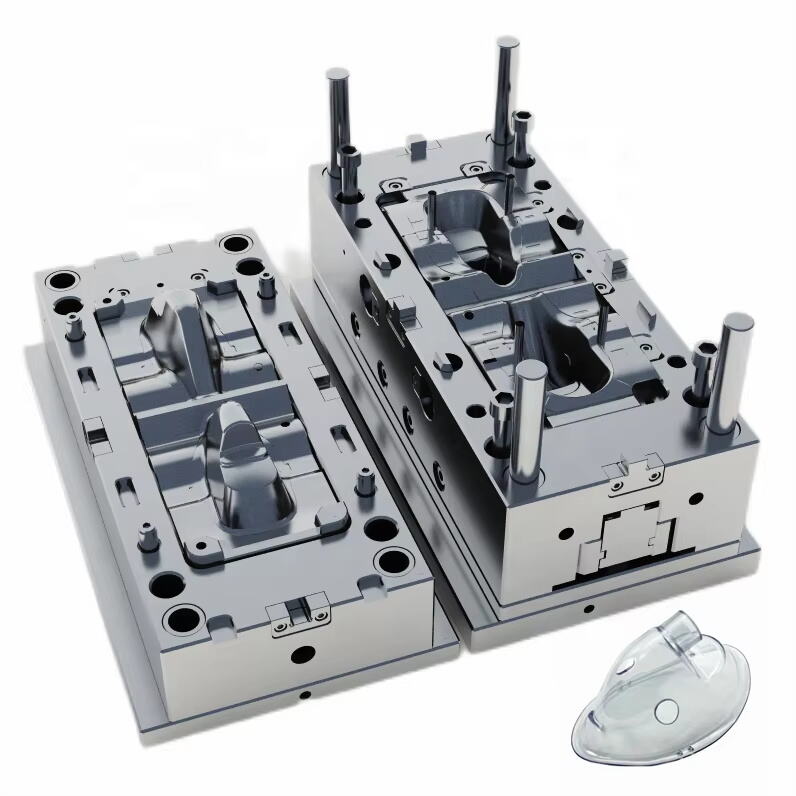

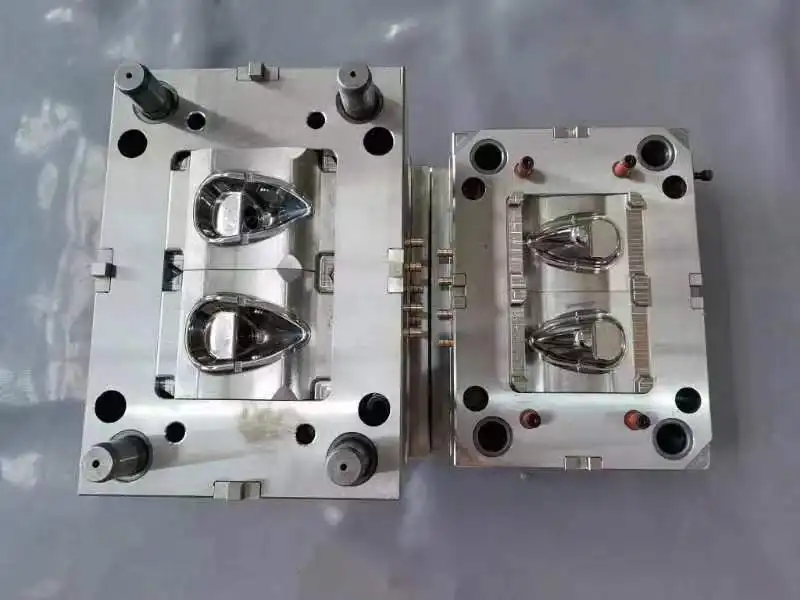

Physical Prototype Development

The creation of physical prototypes remains a crucial aspect of medical device development. Advanced manufacturing techniques, including selective laser sintering, stereolithography, and multi-material 3D printing, enable the production of highly accurate prototypes that closely represent final products. These prototypes undergo extensive testing to verify functionality, durability, and user interaction.

Medical device prototyping at this stage focuses on materials that meet biocompatibility requirements and sterilization standards. Teams must ensure that prototypes accurately represent the intended manufacturing processes and materials for regulatory compliance.

Regulatory Considerations and Testing Protocols

Documentation and Quality Systems

Successful medical device prototyping requires comprehensive documentation of design history, testing procedures, and risk management strategies. Organizations must implement robust quality management systems that align with FDA and international regulatory requirements. This documentation forms the foundation for regulatory submissions and future manufacturing processes.

Teams must maintain detailed records of design changes, testing results, and validation procedures throughout the prototyping process. This systematic approach ensures traceability and demonstrates compliance with quality standards.

Verification and Validation Testing

Prototype testing follows rigorous protocols to verify performance, safety, and efficacy. This includes mechanical testing, electrical safety evaluation, and biocompatibility assessment. Medical device prototyping must incorporate user testing to validate design assumptions and gather real-world usage data.

Organizations often conduct simulated use studies and clinical evaluations to assess device performance under actual conditions. These tests help identify potential risks and validate that the device meets its intended use requirements.

Market Preparation and Manufacturing Scale-up

Design for Manufacturing

As prototypes move toward final development, teams must optimize designs for large-scale production. This involves evaluating manufacturing processes, material costs, and assembly methods. Medical device prototyping in this phase focuses on ensuring consistent quality while maintaining cost-effectiveness.

Teams work closely with manufacturing partners to validate production processes and establish quality control measures. This collaboration helps identify potential manufacturing challenges and implement solutions before full-scale production begins.

Market Launch Strategy

Successful market introduction requires careful planning and coordination across multiple departments. Teams must develop comprehensive training materials, establish distribution networks, and create marketing strategies. The insights gained through medical device prototyping help inform these activities and ensure successful product deployment.

Organizations must also plan for post-market surveillance and continuous improvement processes. This ongoing commitment to product quality and safety extends beyond initial market launch.

Frequently Asked Questions

How long does the medical device prototyping process typically take?

The duration varies significantly depending on device complexity, regulatory requirements, and development approach. Simple devices might complete prototyping in 6-12 months, while complex devices can require 2-3 years or more of prototype development before market readiness.

What are the most common challenges in medical device prototyping?

Key challenges include meeting stringent regulatory requirements, achieving consistent quality across prototypes, managing development costs, and ensuring effective communication between multiple stakeholders throughout the process.

How does rapid prototyping technology impact medical device development?

Rapid prototyping technologies, particularly 3D printing, have revolutionized medical device development by reducing iteration time, lowering costs, and enabling more complex designs. These technologies allow for faster validation of concepts and more efficient design optimization.