Core Benefits of OEM Partnerships in Medical Device Production

Cost Efficiency Through Shared Resource Allocation

Thinking about forming OEM partnerships for medical device manufacturing? There's definitely a financial benefit when it comes to sharing resources. Working with original equipment manufacturers lets businesses cut down on overhead expenses because they don't have to build their own factories from scratch. Shared manufacturing spaces and equipment mean companies avoid those huge upfront costs that can drain capital. Some studies suggest production expenses might drop around 20% when resources are properly allocated across multiple partners. Another money saving aspect appears in how staffing works between partners. When OEMs coordinate hiring efforts, they naturally keep labor costs under control instead of paying for extra workers sitting idle. All things considered, getting costs under control continues to be one of the main reasons why so many companies turn to OEM collaborations in the medical field.

Access to Specialized Technical Expertise

Specialized technical knowledge plays a critical role in modern production environments. When companies partner with OEMs, they gain something most can't achieve internally these days. These relationships connect manufacturers with teams who really know their stuff when it comes to medical devices. The result? Better products because experienced people actually get involved in the development process. What makes these partnerships valuable isn't just about getting better results from day one. Companies also save money and time since they don't have to spend months training staff on complex procedures that OEM experts already handle daily. For many businesses, this kind of ready access to proven talent simply isn't feasible without such collaborations.

Scalability for Fluctuating Production Demands

Does the current production setup cope well when demand goes up and down? Working with original equipment manufacturers brings real advantages in terms of scalability. These partnerships let businesses adjust their manufacturing capacity quickly based on what's happening in the marketplace right now. For industries like medical devices where customer needs can change dramatically from one quarter to the next, this kind of flexibility makes all the difference. When demand spikes, OEMs can ramp up production without breaking a sweat. And during slow periods, companies aren't stuck paying for idle machinery. The bottom line is that these relationships help maintain efficient operations while keeping costs under control, something that becomes increasingly important as markets continue to evolve at breakneck speed.

Navigating Regulatory Compliance in Collaborative Manufacturing

Aligning with FDA & ISO13485 Standards

Looking for help with regulatory compliance issues? When working with original equipment manufacturers (OEMs) in medical device production, following FDA rules and meeting ISO13485 standards isn't just important it's absolutely essential for keeping products safe and reliable. Smart companies know this well because failing to comply can lead to serious problems down the road including hefty fines or worse yet product recalls that hurt both reputation and bottom line. Most OEM partnerships invest heavily in quality control measures throughout their operations. Regular inspections, documentation checks, and employee training programs are all part of maintaining proper compliance levels across the board.

Quality Control in Medical Device Production

The importance of quality control during production cannot be overstated, especially when working with original equipment manufacturers on medical devices. Companies that integrate Total Quality Management approaches into their operations tend to see better results across the board. These methods focus on constantly looking for ways to improve processes before problems occur rather than just fixing issues after they happen. For medical device makers, maintaining strict quality standards isn't just good practice it's absolutely necessary for passing inspections and keeping patients safe. A single oversight can lead to recalls, legal troubles, or worse health risks for users, which makes investing time and resources into quality assurance absolutely worth it in the long run.

Documentation for Audit Readiness

Prepared for compliance audits? Proper documentation is essential for audit readiness in OEM partnerships, acting as a verification tool for regulatory adherence. Partnerships risk penalties without organized records. Software solutions streamline documentation processes, ensuring easy access and audit readiness. Best practices include regular updates and digital archiving.

Technological Integration in Modern OEM Partnerships

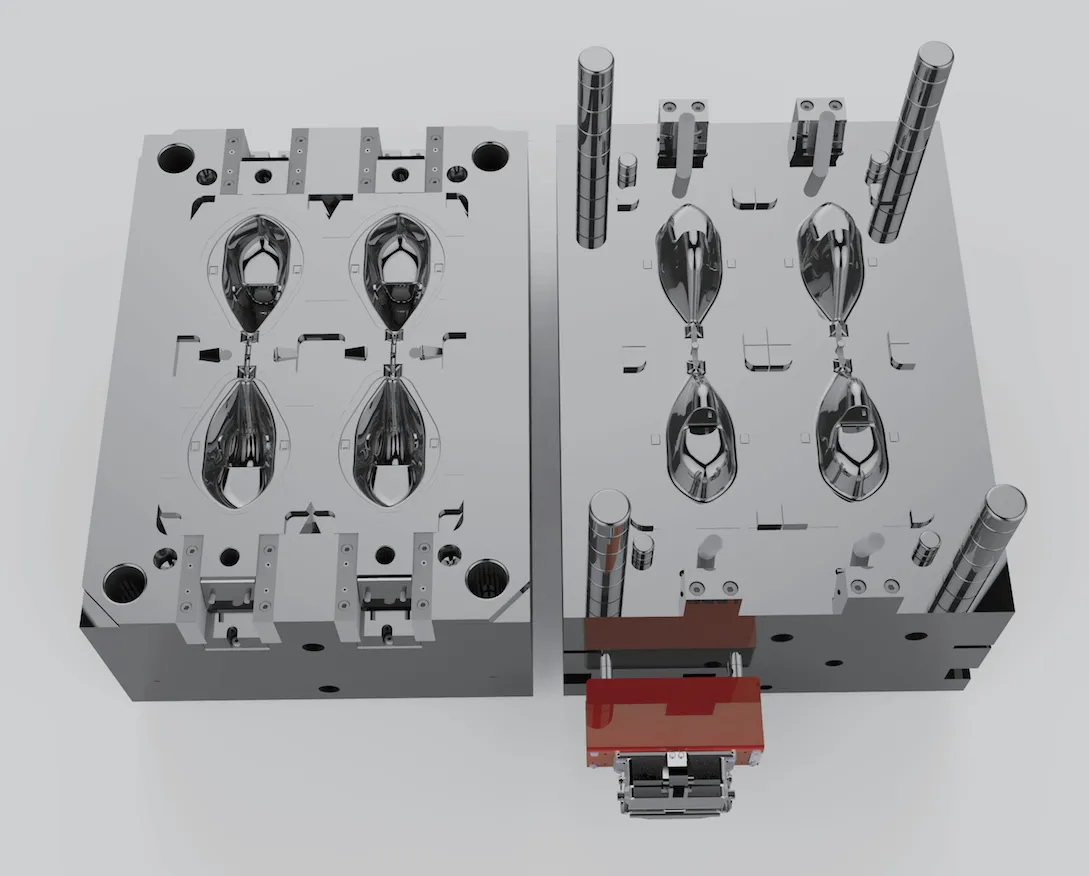

3D Printing for Prototyping and Custom Devices

What makes 3D printing so valuable for businesses? The tech really shakes up how prototypes get made when working with original equipment manufacturers. Companies can slash their time getting products to market because they don't have to wait weeks for traditional manufacturing runs. For medical device makers especially, being able to tweak designs quickly matters a lot. Think about those custom prosthetics that need just the right fit for each person, or dental implants shaped precisely for individual mouths. Beyond better healthcare outcomes, there's another big plus nobody talks about much these days: money saved. Traditional methods often mean throwing away failed prototypes, but with 3D printing, most materials can be reused or recycled after testing different versions.

AI-Driven Process Optimization

Manufacturers are starting to bring AI into their operations these days, mainly to make things run smoother when working with original equipment manufacturers. Artificial intelligence helps automate those boring daily tasks and keeps an eye on equipment before it breaks down, which cuts down on how long each production cycle takes and minimizes wasted materials. Factories that have adopted this tech often see their production cycles shrink by around 30 percent and cut material waste down roughly 25 percent. These numbers show why so many plants are getting serious about incorporating machine learning solutions into their day to day operations.

Automation in High-Volume Production

Looking to streamline high-volume production? Automation plays a pivotal role in maintaining competitiveness within the OEM landscape. Advanced robotics and automated systems enhance productivity while minimizing error rates. Benefits like increased throughput and improved product quality are realized through strategic planning and phased implementation.

Strategic Supply Chain Management for Medical OEMs

Building Resilient Supplier Networks

How resilient is your supply chain? Building resilient supplier networks is crucial for effective supply chain management in the medical OEM sector. Engaging a diverse array of suppliers minimizes risks associated with supply chain disruptions. Upholding industry standards for supplier evaluations and certifications ensures reliability and cost efficiency.

Material Sourcing Best Practices

Are you optimizing your material sourcing strategy? Engaging suppliers who meet regulatory requirements and prioritize quality ensures compliance and cost efficiency. Thoughtful material sourcing decisions enhance a company's reputation and product quality in the medical device market.

Mitigating Production Downtime Risks

How do you mitigate downtime risks in your production process? Mitigating production downtime is crucial for maintaining operational efficiency. Predictive maintenance technologies help forecast potential equipment malfunctions, reducing risks and minimizing financial losses. Embracing predictive maintenance enhances production reliability and efficiency.

FAQ

What is OEM in medical device production?

OEM stands for Original Equipment Manufacturer, and refers to companies that produce equipment which another company sells under its own brand name.

Why are OEM partnerships cost-efficient?

OEM partnerships are cost-efficient because they allow companies to share resources, such as manufacturing facilities and equipment, reducing initial capital investments and operational costs.

How does AI optimize manufacturing processes in OEM partnerships?

AI optimizes manufacturing processes by automating routine tasks, enhancing predictive maintenance, and analyzing data quickly and accurately, thus reducing cycle times and material waste.

Why is quality control important in OEM partnerships?

Quality control ensures that medical devices are safe and effective by implementing continuous improvement strategies and preventing defects, which are crucial to meeting regulatory demands.