The Critical Role of Precision Engineering in Medical Device Manufacturing

In the sophisticated landscape of medical device manufacturing, precision in medical mold production stands as the cornerstone of quality healthcare delivery. The intricate process of creating medical molds demands unwavering attention to detail, advanced technological integration, and strict adherence to regulatory standards. As the healthcare industry continues to evolve, the need for high-precision medical components has never been more crucial.

Medical mold production encompasses the creation of complex tooling used to manufacture various medical devices, from simple syringes to sophisticated surgical instruments. The precision of these molds directly impacts patient safety, treatment efficacy, and medical outcomes. Understanding the fundamental aspects of achieving and maintaining precision in this specialized field is essential for manufacturers and healthcare providers alike.

Essential Components of Precision Medical Molding

Advanced Materials Selection and Validation

The foundation of precise medical mold production begins with selecting appropriate materials. Medical-grade polymers, metals, and composites must meet stringent requirements for biocompatibility, durability, and dimensional stability. Engineers must carefully evaluate material properties such as shrinkage rates, flow characteristics, and thermal stability to ensure consistent part quality.

Material validation processes involve extensive testing protocols, including chemical analysis, mechanical property verification, and long-term stability studies. This comprehensive approach ensures that the selected materials will maintain their critical properties throughout the medical device's intended lifecycle.

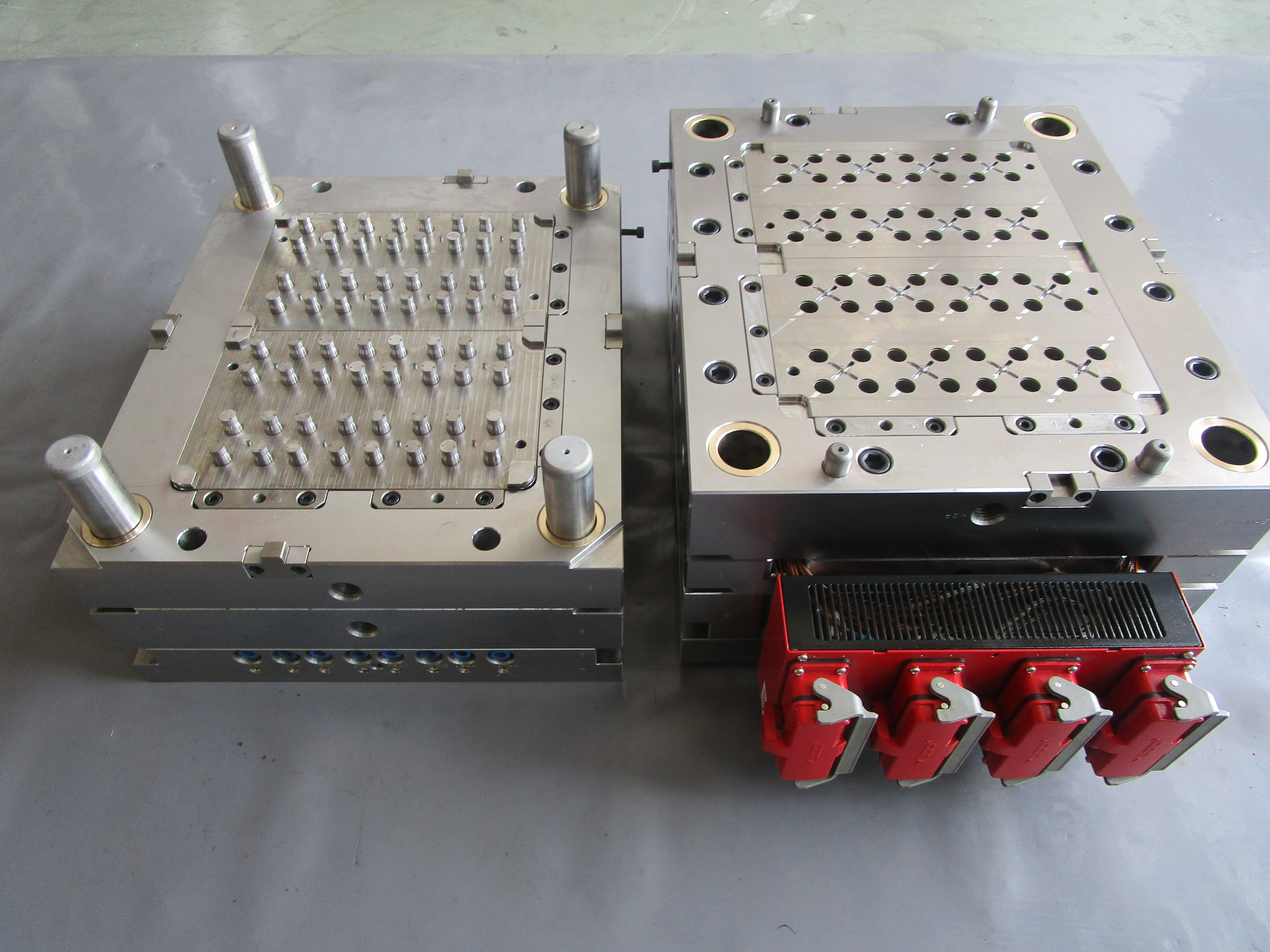

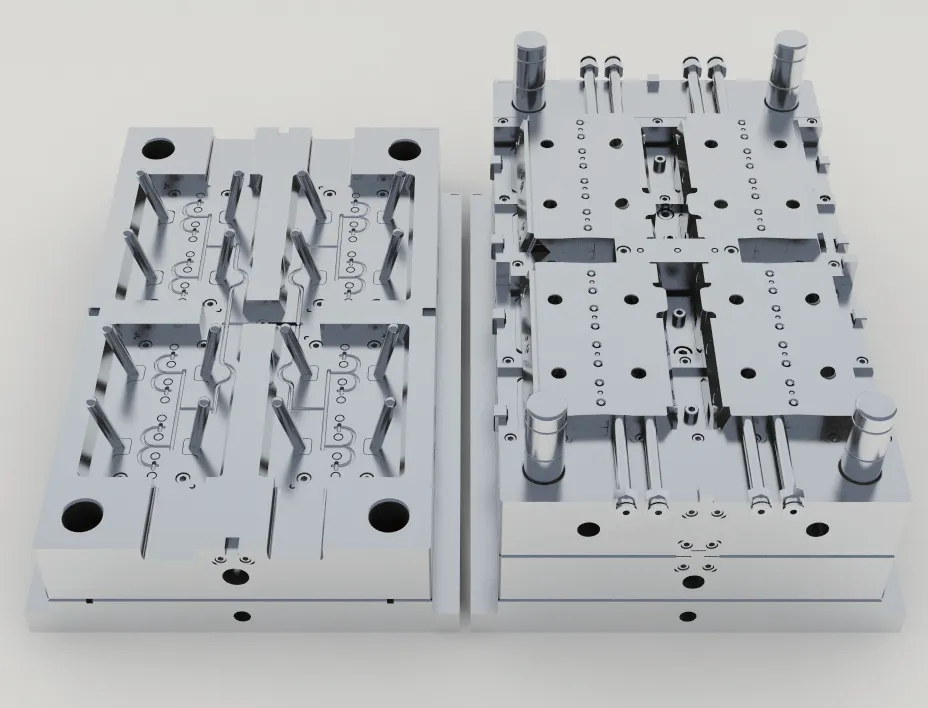

State-of-the-Art Equipment and Technology

Precision in medical mold production relies heavily on cutting-edge manufacturing equipment. Computer Numerical Control (CNC) machining centers, Electric Discharge Machining (EDM) systems, and high-precision measurement devices form the technological backbone of modern medical mold manufacturing.

These advanced systems must be regularly calibrated and maintained to ensure optimal performance. Investment in technology extends beyond machinery to include sophisticated software solutions for design validation, process monitoring, and quality control documentation.

Quality Control Systems and Protocols

Implementing Robust Quality Management Systems

A comprehensive quality management system is essential for maintaining precision in medical mold production. This system should encompass all aspects of the manufacturing process, from initial design through final validation. Documentation requirements, process controls, and verification procedures must align with ISO 13485 standards and FDA regulations.

Regular audits, both internal and external, help ensure compliance and identify opportunities for improvement. Training programs for personnel must be thorough and ongoing to maintain the highest levels of quality consciousness throughout the organization.

Measurement and Inspection Techniques

Advanced metrology equipment and techniques play a vital role in verifying mold precision. Coordinate Measuring Machines (CMM), optical measurement systems, and 3D scanning technologies provide detailed dimensional analysis of mold components. These measurements must be documented and tracked to establish process capability and identify potential trends.

Regular calibration of measurement equipment ensures accuracy and reliability of inspection results. Implementation of statistical process control methods helps monitor and maintain consistent quality levels in medical mold production.

Process Validation and Documentation

Design Validation Procedures

Before beginning production, thorough design validation ensures that medical molds will produce components meeting all specifications. This includes computer-aided engineering analysis, prototype testing, and design review processes. Simulation software helps predict potential issues before significant resources are invested in tooling.

Documentation of design validation must be comprehensive and maintained throughout the product lifecycle. Changes to design parameters require careful evaluation and revalidation to ensure continued precision in production.

Production Process Validation

Process validation in medical mold production involves establishing documented evidence that the manufacturing process consistently produces parts meeting predetermined specifications. This includes Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ) protocols.

Continuous monitoring and periodic revalidation ensure that processes remain in control and capable of maintaining required precision levels. Process parameters must be clearly defined and controlled within validated ranges.

Maintaining Long-term Precision

Preventive Maintenance Strategies

Regular maintenance of molds and production equipment is crucial for sustained precision. Detailed maintenance schedules, cleaning protocols, and wear monitoring procedures help prevent unexpected failures and quality issues. Documentation of maintenance activities provides traceability and supports continuous improvement efforts.

Implementing predictive maintenance technologies can help identify potential issues before they impact production quality. This proactive approach helps maintain consistent precision while minimizing production interruptions.

Environmental Control and Monitoring

The production environment significantly impacts precision in medical mold production. Temperature, humidity, and cleanliness must be carefully controlled and monitored. Environmental monitoring systems should provide real-time data and alerts when conditions deviate from specified ranges.

Regular validation of environmental control systems ensures their effectiveness in maintaining required conditions. Documentation of environmental monitoring provides evidence of control and supports regulatory compliance.

Frequently Asked Questions

What are the key factors affecting precision in medical mold production?

The primary factors include material selection, equipment capability, environmental conditions, operator training, and quality control systems. Each factor must be carefully controlled and monitored to maintain required precision levels.

How often should medical molds be inspected and validated?

Medical molds should undergo regular inspection based on usage frequency, typically every 5,000 to 10,000 cycles. Full validation should be performed annually or when significant changes occur in the process or equipment.

What role does automation play in ensuring precision?

Automation helps maintain consistent process parameters, reduce human error, and provide detailed documentation of production conditions. Advanced robotics and control systems contribute significantly to achieving and maintaining precision in medical mold production.