Understanding the Investment in Medical Device Manufacturing

Medical mold development represents a critical component in healthcare manufacturing, requiring precision engineering and strict adherence to regulatory standards. The intricate process of creating molds for medical devices involves substantial planning, expertise, and resources to ensure the final products meet the exacting demands of the healthcare industry.

The journey from concept to finished medical mold encompasses multiple stages, each contributing to both the timeline and overall cost structure. Manufacturing facilities must carefully balance quality requirements with economic considerations while maintaining compliance with regulatory frameworks such as FDA guidelines and ISO standards.

Key Cost Components in Medical Mold Development

Material Selection and Quality Standards

The choice of materials significantly impacts the cost of medical mold development. Medical-grade materials must meet stringent purity requirements and maintain stability under various conditions. High-performance polymers and specialty steel alloys commonly used in medical molds command premium prices due to their superior properties and certification requirements.

Quality validation processes for materials add another layer of expense, as each batch requires testing and documentation to ensure compliance with medical standards. These materials must demonstrate biocompatibility, resistance to sterilization processes, and long-term stability – factors that directly influence the overall cost structure.

Design and Engineering Expertise

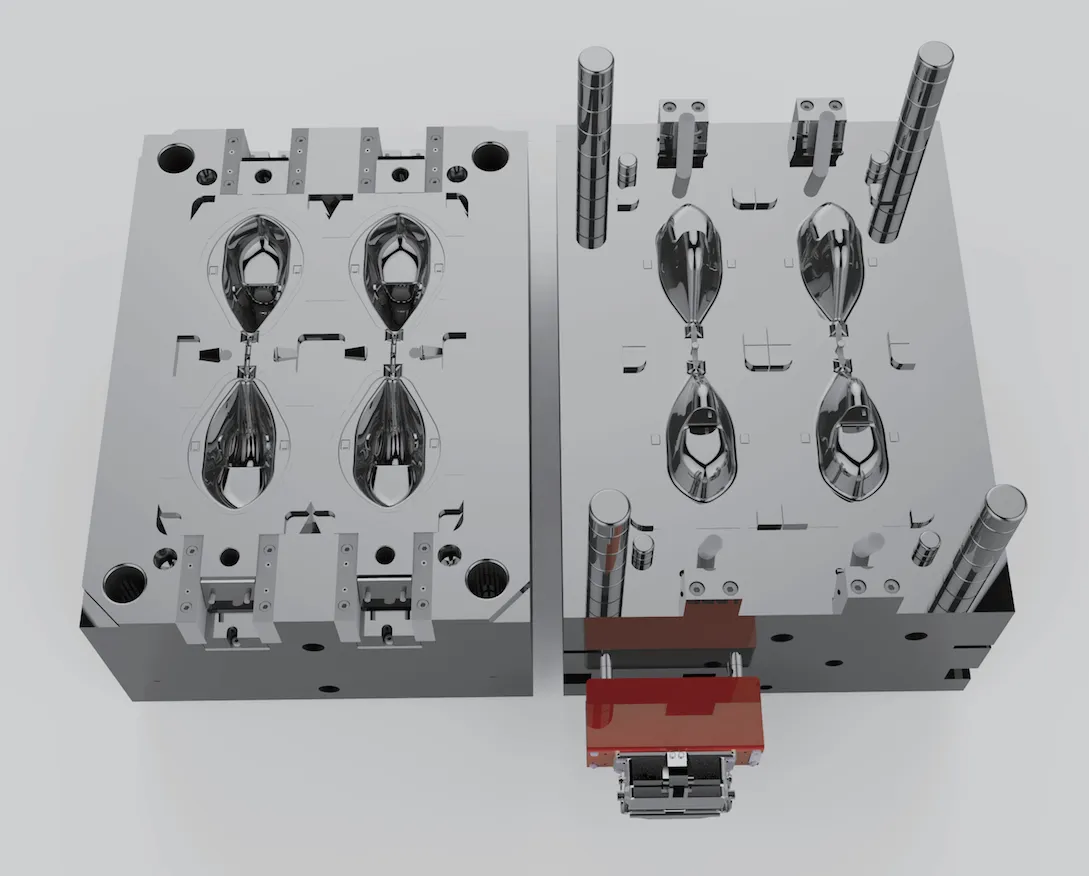

Professional engineering expertise represents a substantial investment in medical mold development. Skilled designers and engineers must dedicate considerable time to creating precise technical specifications, conducting flow analyses, and optimizing designs for manufacturability. Their specialized knowledge ensures the mold will produce consistent, high-quality medical components.

Advanced software tools and simulation programs used in the design phase also contribute to development costs. These technologies help prevent costly errors before physical production begins, ultimately saving time and resources in the long run.

Timeline Considerations in Medical Mold Production

Development Phases and Milestones

The timeline for medical mold development typically spans several months, depending on complexity and regulatory requirements. Initial concept development and design validation can take 4-6 weeks, while prototyping and testing phases may extend several more months. Each milestone must be carefully documented and verified to ensure compliance with medical device regulations.

Project managers must account for potential iterations and refinements throughout the development process. Unexpected challenges or design modifications can impact the timeline, making it crucial to build flexibility into project schedules while maintaining clear communication with stakeholders.

Regulatory Compliance and Documentation

Securing necessary approvals and certifications adds significant time to medical mold development. Regulatory bodies require extensive documentation, validation testing, and quality system compliance. These requirements can add weeks or months to the development timeline but are essential for ensuring product safety and legal compliance.

Manufacturing facilities must maintain detailed records of material traceability, process controls, and quality testing throughout the development cycle. This documentation becomes part of the product's technical file and supports regulatory submissions.

Optimization Strategies for Cost and Time Management

Advanced Manufacturing Technologies

Implementing cutting-edge manufacturing technologies can help optimize both cost and time factors in medical mold development. Automated systems, precision machining centers, and advanced monitoring equipment improve efficiency while maintaining the high quality standards required for medical applications.

Digital manufacturing solutions and Industry 4.0 technologies enable better process control and real-time monitoring, reducing the risk of errors and minimizing production delays. These investments in technology often lead to long-term cost savings through improved productivity and reduced waste.

Strategic Planning and Resource Allocation

Effective project management and resource allocation play crucial roles in controlling costs and meeting timelines. Creating detailed project plans, identifying potential bottlenecks, and maintaining adequate staffing levels help ensure smooth progression through development phases.

Regular review meetings and progress assessments allow teams to identify and address challenges early, preventing costly delays and maintaining project momentum. Building strong relationships with material suppliers and service providers also helps optimize lead times and manage costs effectively.

Future Trends Affecting Medical Mold Development

Emerging Technologies and Innovation

The medical mold development landscape continues to evolve with new technologies and manufacturing approaches. Additive manufacturing, artificial intelligence, and advanced materials science are creating opportunities for faster, more efficient development processes.

These innovations promise to reduce both costs and development times while maintaining or improving product quality. Companies investing in research and development stay ahead of industry trends and position themselves for future success.

Sustainability and Cost Efficiency

Environmental considerations are increasingly influencing medical mold development decisions. Sustainable materials and energy-efficient manufacturing processes not only reduce environmental impact but can also lead to long-term cost savings.

Organizations are exploring recycling programs, energy management systems, and waste reduction initiatives to optimize their operations while meeting growing demands for sustainable manufacturing practices.

Frequently Asked Questions

What factors most significantly impact medical mold development costs?

The most significant cost factors include material selection, engineering expertise, regulatory compliance requirements, and the complexity of the mold design. Advanced materials and precise engineering specifications typically represent the largest portion of development costs.

How long does typical medical mold development take?

Medical mold development usually requires 3-6 months from concept to completion, depending on complexity and regulatory requirements. Simple molds might be completed in less time, while complex projects with extensive validation requirements can take longer.

What strategies can reduce medical mold development time without compromising quality?

Implementing advanced manufacturing technologies, maintaining efficient project management practices, and utilizing simulation software for design validation can help reduce development time while maintaining quality standards. Early involvement of regulatory experts can also streamline the approval process.