ISO Class 8 Clean Rooms: An Overview

Clean rooms rated at ISO Class 8 serve important functions in places where keeping things really clean matters, especially when making medical devices. The ISO 14644-1 standard sets limits here too, allowing no more than around 3.5 million floating particles in each cubic meter of space. Controlling air quality this tightly becomes absolutely necessary for businesses needing to keep contaminants away from what they produce. Within these Class 8 spaces, both particle count and their sizes get monitored carefully. That makes them good choices for operations involving things like plastic injection molding techniques commonly applied to create components for health care equipment and other delicate applications across different sectors.

ISO Class 8 clean rooms play a really important role in injection molding operations. When companies keep these standards up, they prevent mold contamination that might otherwise ruin the effectiveness of finished products. This matters most in industries such as medical device production, where even tiny impurities can cause serious problems because everything needs to be spotless and exact. Following these cleaning rules helps manufacturers create better products overall while staying within all the required regulations. For businesses providing injection molding services, this means delivering consistently good quality without any contaminants, which builds trust among clients and strengthens their position in competitive markets.

Key Quality Standards for Injection Molds

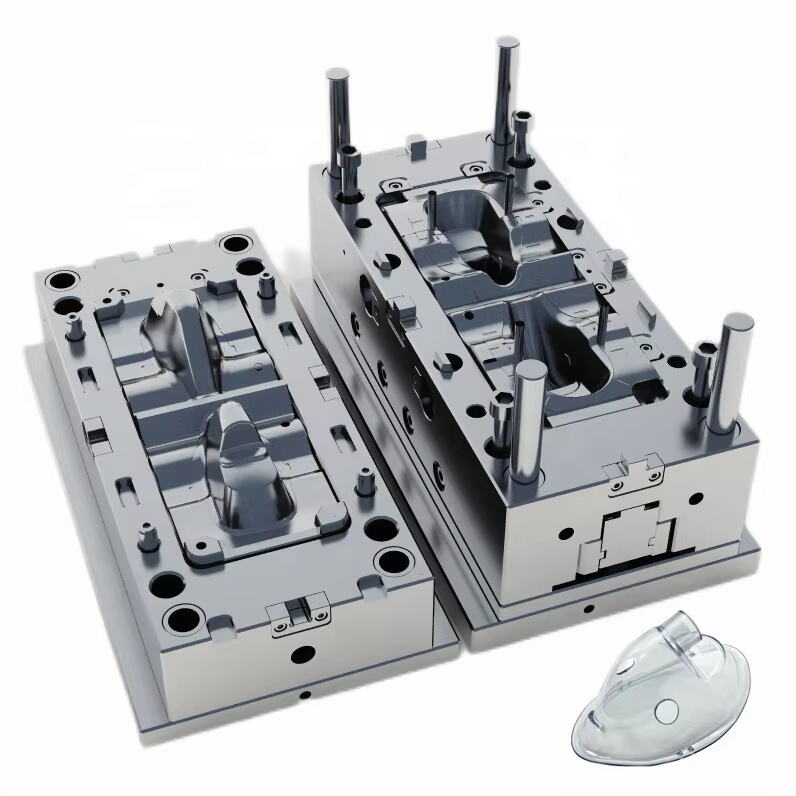

Precision and Tolerances in Mold Design

Getting the mold design right matters a lot if we want our molded parts to hit those exact size specs. When it comes to injection molding, those tight tolerances really count because they make sure everything fits together properly once assembled. Take some industries where specs get super strict sometimes, down to plus or minus 0.001 inches on certain parts. That kind of accuracy takes serious attention to detail during design and some pretty sophisticated machining work. Most good shops know this stuff inside out since meeting those tough standards isn't just about looking good it's actually what keeps customers happy and gets past all the regulations that come with manufacturing plastics these days.

Surface Finish Requirements

How smooth or rough an injection mold's surface is makes all the difference in the quality and function of what comes out of it. When surfaces are really smooth, there's less friction during production, so products look better and work more efficiently. Most factories follow something called RA values to measure roughness and make sure their molds meet certain texture requirements. Sticking to these guidelines means fewer headaches down the line because parts usually come out ready to go without needing extra finishing work. Take the medical device industry for instance they absolutely rely on this because even tiny imperfections can matter a lot when making things like surgical instruments or implants where precision isn't just nice to have it's essential for patient safety.

Material Compatibility and Selection

Getting the material choice right for injection molds makes all the difference when it comes to how long the mold lasts and what kind of products come out of it. Steel and aluminum are typical options, each bringing their own advantages to the table. Heat resistance matters a lot, so does the strength of the material under pressure. The chosen material needs to work well within the injection molding setup itself, standing up to the harsh conditions inside the machine while still producing quality parts. For medical grade plastics especially, where there's no room for error, picking materials that won't break down over time becomes absolutely critical. Thermal properties play a big role here too since temperature fluctuations during production can really impact both mold life and finished product consistency in these demanding applications.

Clean Room Compliance for Injection Molds

Contamination Control Measures

Getting contamination under control in ISO Class 8 cleanrooms matters a lot when it comes to keeping molded products safe from defects. The usual approach involves fancy air filters to catch particles, restricted entry points so people don't bring in dirt, and strict rules about what workers wear before entering. Standards such as ISO 14644-1 basically say we need to keep track of both dust floating around and any microbes that might sneak in. Training sessions happen regularly for everyone working there because nobody wants to mess up quality control. When staff really get why they follow certain steps during production, they're less likely to skip them accidentally. And this attention to detail makes all the difference in delivering products customers can trust won't fail later down the line.

Air Particle Limits and Monitoring

Clean rooms classified as ISO Class 8 have strict rules about airborne particles, limiting them to just 3,520 particles at or above 0.5 micrometers per cubic meter of air. Sticking to these standards matters a lot when making precision molds, particularly important in fields such as medical devices where even tiny contaminants can cause big problems. The monitoring equipment constantly checks not only how many particles are floating around but also looks at other environmental factors too. When something goes out of spec, these systems let operators know right away so they can fix whatever's wrong before it affects product quality. Keeping everything within those tight parameters through constant watchfulness makes all the difference in places where getting things wrong could lead to serious consequences down the line.

Cleaning and Maintenance Protocols

Keeping up with regular cleaning routines inside clean rooms remains essential for protecting the quality of our molding operations. Most facilities stick to non-abrasive cleaners because they don't scratch surfaces, while also employing methods that won't disturb the delicate balance of particles in the air. We schedule routine checks on all these cleaning practices too. These inspections help spot areas where we could do better and make sure we meet those tough industry standards like ISO 14644. Companies that neglect their cleaning schedules often run into problems later on. Contaminants tend to accumulate over time, which can really mess with product specs and create headaches during production runs. A good cleaning program isn't just about ticking boxes though it actually makes business sense in the long run.

Testing and Certification for Injection Molds

Dimensional Accuracy Testing

Checking dimensional accuracy remains essential when making sure injection molds hit their target specs. Most shops rely on tools like coordinate measuring machines, or CMMs for short, to get down to the nitty gritty of component measurements. These machines basically take super detailed readings so every part fits within those tight tolerance ranges specified during design. The whole point of this thorough checking process? To cut down on defects once production ramps up, which means better quality products heading out the door and happier customers at the end of the line. Medical device manufacturers know this all too well since even minor dimensional issues can spell disaster for implantable parts. That's why they invest heavily in these tests to keep their products safe and reliable for patients who depend on them day in and day out.

Mold Performance Evaluation

When looking at how well injection molds perform, most attention goes to three main areas efficiency, how long they last, and the actual quality of what comes out of them. During evaluations, people typically check things like how fast each cycle runs and whether the mold keeps producing consistently over time. Statistical process control, or SPC for short, has become pretty standard across the industry for spotting when something starts going off track. Many plants find that using SPC lets them tweak operations before problems get serious, which means better overall performance from day to day. Manufacturers who want to keep up with competition and satisfy those tough industry standards usually end up spending time on these assessments regularly. Beyond just making production smoother, this kind of monitoring actually cuts costs down the road while keeping products dependable in the market.

ISO Certification Process

Getting ISO certified for injection molds means going through a detailed check against established industry norms and best practices. The whole process requires lots of paperwork and proving that every step meets requirements, especially around quality checks and making ongoing improvements. When companies actually get through this certification process, it really boosts their reputation in the market and shows they take quality seriously. For businesses operating in critical sectors such as medical devices or drug manufacturing, having reliable, safe parts from molds is absolutely essential. That's why these industries pay extra attention to suppliers with proper certifications. After all, when something goes wrong with a component used in patient care equipment, there's no room for excuses. Manufacturers with ISO certification tend to win more business simply because potential customers see those letters as proof that quality isn't just talked about, but actually practiced day after day.

Applications in Sensitive Industries

Medical Device Manufacturing

Medical device manufacturing relies heavily on injection molding processes because there are so many rules to follow in this industry. Most companies need to operate their production lines inside ISO Class 8 clean rooms just to keep medical products uncontaminated. These special environments help eliminate dust buildup, chemical fumes, and all sorts of microscopic particles that could ruin sensitive equipment. Manufacturers working with the FDA and other regulatory bodies have no choice but to stick strictly to their cleaning protocols and quality checks. All these regulations aren't just paperwork either they actually make sure that devices stay safe and functional when doctors use them on patients. A single mistake in the process can lead to recalls or worse, harm to people who depend on these life-saving tools every day.

Pharmaceutical Production

For drug manufacturing, keeping injection molded parts clean isn't just important it's absolutely essential for making sure medications work properly and don't harm patients. These parts get made in special clean rooms where dust particles and other contaminants must be kept at bay. The rules about what counts as clean enough are extremely strict. Companies have no choice but to run frequent checks and tests if they want to stay compliant with all the regulatory requirements. All this extra care pays off though because it means doctors can trust that the components used in syringes, vials and other medical devices won't compromise patient safety. Without such strict controls, even tiny amounts of contamination could render entire batches of medication useless or worse, dangerous.

Electronics and Microtechnology

Injection molding plays a critical role in making precision parts across electronics and microtechnology industries. For many manufacturers, working in ISO Class 8 clean rooms has become standard practice because these controlled environments prevent dust and other contaminants from ruining sensitive components during production. The latest manufacturing tech keeps getting better at meeting those exacting quality requirements. CNC machines, automated inspection systems, and real-time monitoring all help ensure parts come out exactly as specified. Without these advanced capabilities, it would be nearly impossible to keep up with the ever tightening tolerances demanded by modern electronic devices and microscale components.

Conclusion: Importance of Adhering to Standards for Reliable and Safe Production

Keeping strict quality controls during injection mold manufacturing makes all the difference when producing dependable, safe goods. This becomes even more critical in fields like healthcare and medicine where mistakes aren't just costly they can literally put lives at risk. The medical industry cannot afford anything less than perfection because contaminated equipment or medications could lead to serious patient harm. That's why many facilities maintain ISO Class 8 clean room environments during production these controlled spaces help stop unwanted particles from getting into sensitive materials. For manufacturers working in these regulated areas, following these standards isn't just good business practice it's often legally required by governing bodies overseeing product safety across the board.

Keeping up with ISO Class 8 clean room requirements shows manufacturers care about doing things right while also making customers feel confident about what they buy. When companies stick to these strict quality controls, their products stay safe and work as intended, which builds real trust over time. Following these standards goes beyond just checking boxes on paperwork. It actually makes people who invest in the company feel secure knowing the goods live up to top quality expectations. For businesses working in industries where mistakes cost money or lives, this kind of commitment isn't optional it's essential for staying competitive and respected in the marketplace.

FAQs

What is an ISO Class 8 clean room?

An ISO Class 8 clean room is a controlled environment specified by ISO 14644-1, which regulates air quality by limiting airborne particles to a maximum of 3,520,000 particles per cubic meter.

Why is ISO Class 8 clean room compliance important in injection molding?

Compliance ensures that the molds are free from contamination, maintaining the quality and integrity of the final product, crucial in sectors like medical device manufacturing.

What industries benefit from ISO Class 8 clean rooms?

Industries such as medical device manufacturing, pharmaceutical production, and electronics benefit from ISO Class 8 clean rooms due to their need for contaminant-free production environments.

How are air particle levels monitored in ISO Class 8 clean rooms?

Air particle levels are monitored using continuous monitoring systems that track both particle count and environmental conditions, allowing for immediate corrective actions if necessary.