Medical Products

|

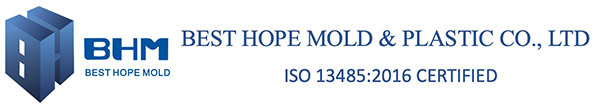

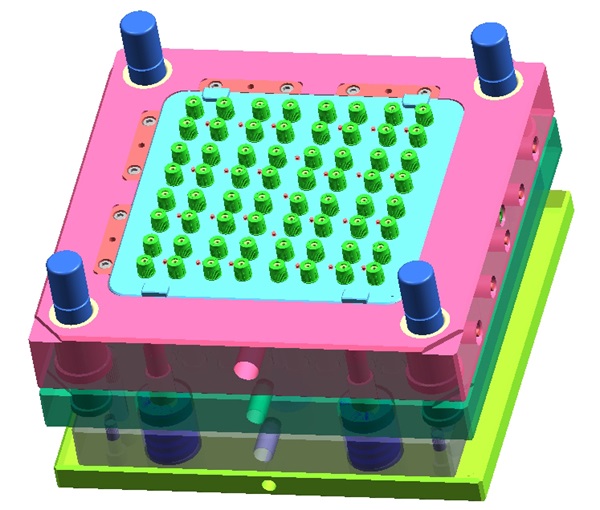

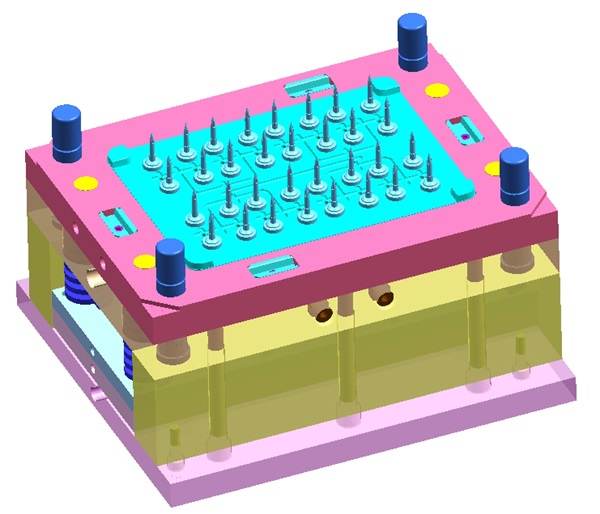

Engineering DesignDesign for manufacturability and sfficient production is our primary objective. With advance CAD/CAM/CAE systems, such as Pro-E, Solidworks, UG, AutoCAD, Mold flow analysis, we can provide you different file formats drawing in 2-4 days. According with sample do part design and mold design or using clients part drawing for tooling all is what we can fully cooperate with. Runner balance to ensure part accurate dimension. Sufficient cooling system guarantee the fastest cycle time. Runner and part weight strictly control. We always will help each clients do the part design analysis before tooling,prevent any issue from part design. During mold shipping,all technical drawing for part and mold will be shipped together with mold.Mold drawing should be same as the real mold making.

|

| Links: | |

| 2006 Copyright © Best Hope Mold & Plastic Co., Ltd Headquarter:2503,No 158 Rongyue Road,Zhongshan Street,Songjiang District,201613,Shanghai Plant:Bld45, No.99, Xinda Rd. Huimin Street, Jiashan City,314100, Zhejiang, China

|

Medical: www.bh-med.com; Mold Tooling: www.bh-mold.net Email: bhm@bh-med.com; bhmould@bhmould.com Tel: +86-18121109009 Mob: 008618121109009 |